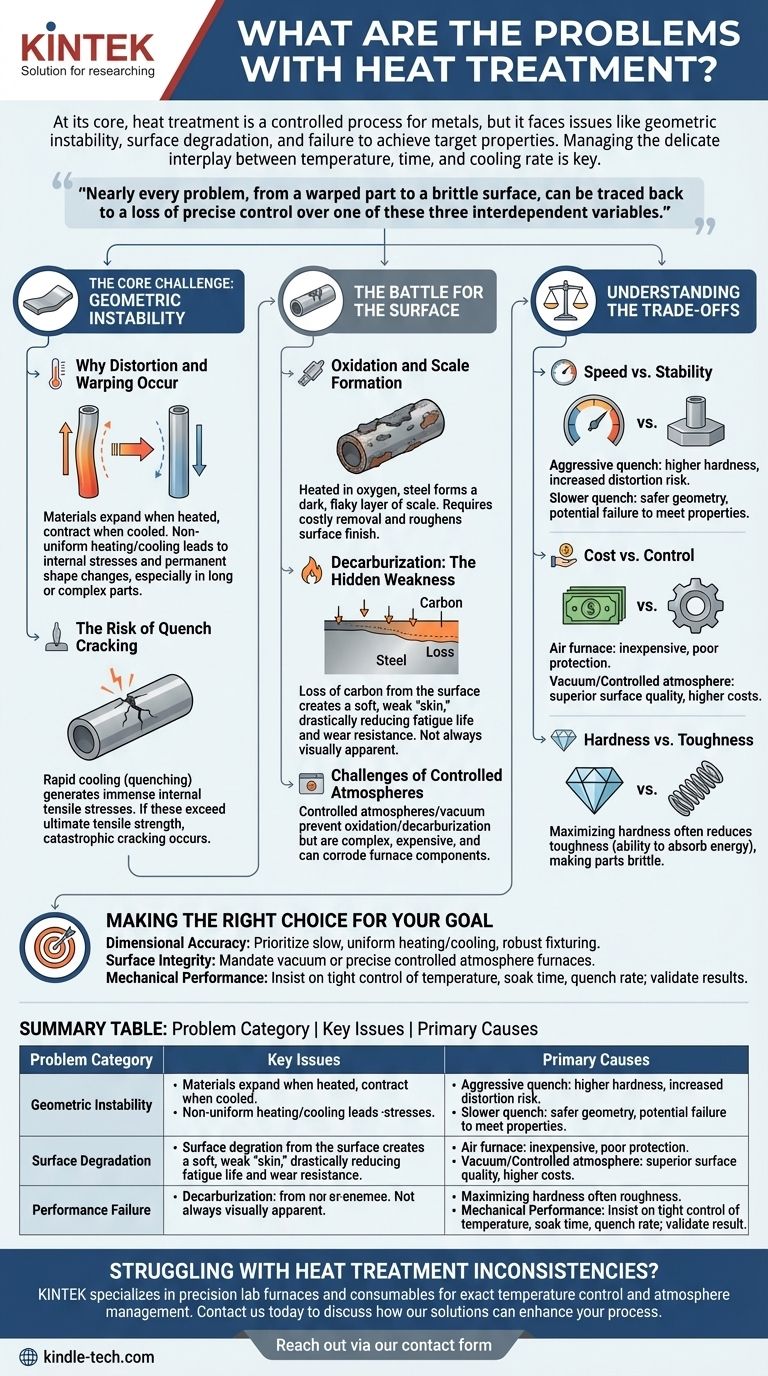

At its core, heat treatment is a controlled process of heating and cooling metals to achieve desired mechanical properties, but it is fraught with potential problems. The most common issues fall into three categories: geometric instability like distortion and cracking, surface degradation such as scaling and decarburization, and the failure to achieve the target hardness or microstructure, leading to inconsistent performance.

The fundamental challenge of heat treatment is not just preventing individual defects, but managing the delicate interplay between temperature, time, and cooling rate. Nearly every problem, from a warped part to a brittle surface, can be traced back to a loss of precise control over one of these three interdependent variables.

The Core Challenge: Geometric Instability

The most visibly dramatic failures in heat treatment involve the part losing its intended shape or fracturing entirely. These issues stem from the intense thermal and transformational stresses induced during the process.

Why Distortion and Warping Occur

All materials expand when heated and contract when cooled. When this happens non-uniformly across a part—due to its geometry or uneven furnace temperatures—internal stresses build up.

These stresses are then relieved as the material yields at high temperatures, resulting in permanent changes to the part's shape. This is why long, thin parts or those with complex geometries are especially prone to warping.

The Risk of Quench Cracking

Quenching, or rapid cooling, is necessary to achieve high hardness in steels. However, it is also the point of highest risk.

As the part's surface cools and transforms much faster than its core, immense internal tensile stresses are generated. If these stresses exceed the material's ultimate tensile strength, catastrophic cracking will occur, rendering the part useless.

The Battle for the Surface

A part's surface is its interface with the world, and heat treatment can unfortunately degrade it. Protecting the surface chemistry and finish is a critical, and often complex, aspect of the process.

Oxidation and Scale Formation

When heated in the presence of oxygen (i.e., in an open-air furnace), steel rapidly forms a dark, flaky layer of iron oxide known as scale.

This scale must be removed through costly secondary processes like sandblasting or acid pickling. It also results in a rough surface finish and a small amount of material loss.

Decarburization: The Hidden Weakness

Decarburization is the loss of carbon from the surface of steel. It occurs at high temperatures when the furnace atmosphere has a lower carbon potential than the steel itself.

This creates a soft, weak "skin" on the part, which drastically reduces fatigue life and wear resistance. It is a particularly dangerous defect because it is not always visually apparent.

Challenges of Controlled Atmospheres

To prevent oxidation and decarburization, parts are often heat-treated in controlled atmospheres or a vacuum. However, this introduces its own set of problems.

Managing the precise composition of process gases is complex and expensive. Furthermore, certain atmospheres can be corrosive, causing erosion and premature failure of the furnace's electric heating elements and other internal components.

Understanding the Trade-offs

Choosing the right heat treatment process always involves balancing competing priorities. Understanding these trade-offs is key to avoiding common pitfalls.

Speed vs. Stability

A more aggressive quench yields higher hardness but dramatically increases the risk of distortion and cracking. A slower quench is safer from a geometric standpoint but may fail to produce the required mechanical properties.

Cost vs. Control

Heat treating in an air furnace is inexpensive but offers almost no protection against scale and decarburization. A vacuum or controlled atmosphere furnace provides superior surface quality but comes with significantly higher equipment and operational costs.

Hardness vs. Toughness

This is a fundamental material trade-off. Processes that maximize hardness, a material's resistance to indentation and wear, often reduce its toughness, which is its ability to absorb energy and resist fracture. A part that is too hard can become brittle and fail unexpectedly in service.

Making the Right Choice for Your Goal

Successfully navigating the challenges of heat treatment requires aligning your process with your most critical engineering requirement.

- If your primary focus is dimensional accuracy: Prioritize slow, uniform heating and cooling, and use robust fixturing to support the part and minimize distortion.

- If your primary focus is surface integrity: Mandate the use of vacuum or precisely controlled atmosphere furnaces to prevent oxidation and decarburization.

- If your primary focus is mechanical performance: Insist on tight control over all process parameters—temperature, soak time, and quench rate—and validate the results with rigorous testing.

Understanding these inherent challenges is the first step toward mastering the heat treatment process and ensuring reliable outcomes.

Summary Table:

| Problem Category | Key Issues | Primary Causes |

|---|---|---|

| Geometric Instability | Distortion, Warping, Quench Cracking | Non-uniform heating/cooling, thermal stresses, rapid quenching |

| Surface Degradation | Scaling, Decarburization, Oxidation | Exposure to oxygen, improper furnace atmosphere |

| Performance Failure | Inconsistent hardness, brittle microstructure | Poor control of temperature, time, or cooling rate |

Struggling with heat treatment inconsistencies? KINTEK specializes in precision lab furnaces and consumables that deliver the exact temperature control and atmosphere management needed to prevent distortion, cracking, and surface defects. Our equipment ensures your materials achieve the desired hardness, microstructure, and dimensional stability—every time. Contact us today to discuss how our solutions can enhance your heat treatment process and improve your lab's efficiency. Reach out via our contact form for a personalized consultation!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Sintering Brazing Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is 1800 degrees Celsius furnace? A Guide to High-Temperature Materials Processing

- What is the function of the EAF? Powering a Sustainable, Agile Future for Steel Production

- Is a brazed joint strong? Yes, It Can Be Stronger Than the Base Metal

- What materials are used in vacuum braze? A Guide to Metals, Alloys, and Filler Selection

- How does the isothermal holding function of high-temperature furnaces affect TLP bonding joints? Achieve Seamless Bonds

- What is the heat treatment process of quench hardening? A Guide to Achieving Maximum Hardness

- How thick is the plasma nitriding layer? Tailor Case Depth from 0.05mm to 0.5mm for Your Needs

- Why is a vacuum drying oven required for Si-FG post-treatment? Preserving Chemical Integrity of Graphene