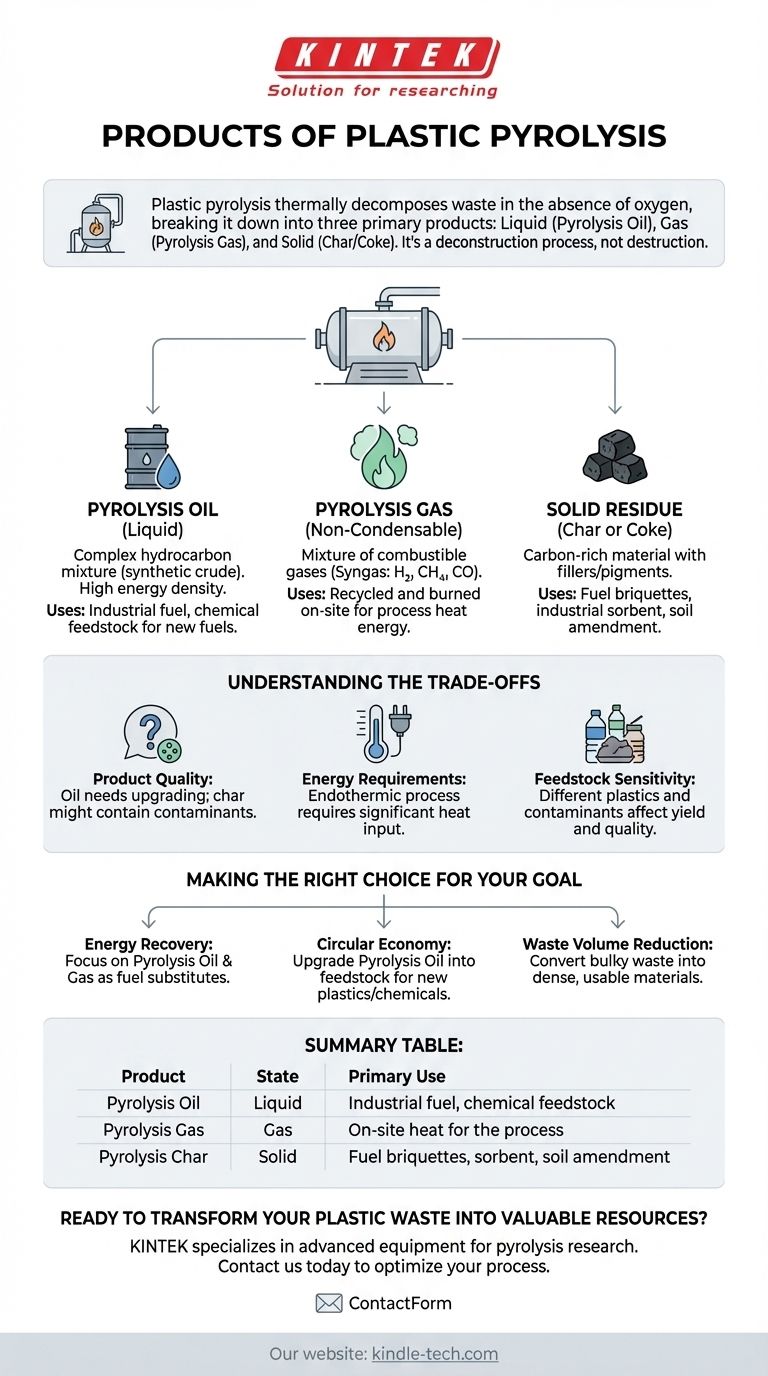

In essence, plastic pyrolysis thermally decomposes plastic waste in the absence of oxygen, breaking it down into three primary products: a liquid hydrocarbon mixture called pyrolysis oil, a non-condensable combustible gas, and a solid carbonaceous residue often called char or coke. A fourth potential byproduct, wastewater, is generated only if the initial plastic feedstock contains moisture.

The core function of pyrolysis is not to destroy plastic but to deconstruct it. The process reverses the original manufacturing process, breaking down long, complex polymer chains into simpler, smaller, and more valuable molecules that can be used as fuel or chemical feedstock.

The Three Core Products of Plastic Pyrolysis

The exact yield and composition of each product depend heavily on the type of plastic being processed and the specific conditions of the pyrolysis reactor (e.g., temperature, pressure). However, the output can always be categorized into three distinct states of matter.

Pyrolysis Oil (Liquid)

Pyrolysis oil, sometimes called synthetic crude, is the primary liquid product. It is a complex mixture of various hydrocarbon compounds.

This oil is extracted by cooling the hot gases that exit the pyrolysis reactor. It has a high energy density and can be used directly as a fuel in industrial furnaces or boilers. More advanced applications involve refining it to produce valuable fuels like biodiesel or other chemical feedstocks.

Pyrolysis Gas (Non-Condensable Gas)

This product is a mixture of gases that do not condense into a liquid when cooled. It is often referred to as "syngas" or synthesis gas.

The gas is rich in combustible components, including hydrogen (H₂), methane (CH₄), carbon monoxide (CO), and various other light hydrocarbons (CnHm). A key feature of most pyrolysis plants is that this gas is recycled and burned on-site to provide the heat energy required to sustain the pyrolysis reaction, making the process more energy-efficient.

Solid Residue (Char or Coke)

After the volatile components have been driven off as gas, a solid, carbon-rich material remains. This product is variously referred to as pyrolysis char, coke, or biochar.

This solid residue is composed primarily of carbon, mixed with any inert materials (like fillers or pigments) present in the original plastic. It has several potential uses, including being pressed into briquettes for fuel, used as an industrial sorbent, or even as an agricultural soil amendment.

Understanding the Trade-offs

While a powerful technology, plastic pyrolysis is not a perfect solution. Understanding its limitations is key to evaluating its role in waste management and energy production.

Product Quality and Contamination

The pyrolysis oil is not a direct substitute for refined fossil fuels. It often requires further processing and upgrading to remove impurities and stabilize its properties before it can be used as a transportation fuel. Similarly, the solid char can contain heavy metals or other contaminants from the original plastic waste, which may restrict its use in certain applications.

Process Energy Requirements

Pyrolysis is an endothermic process, meaning it requires a significant input of heat energy to break the chemical bonds in the plastic polymers. While the pyrolysis gas is typically used to self-sustain the reaction, the initial startup and process control demand a carefully managed energy balance.

Feedstock Sensitivity

The process is highly sensitive to the type and cleanliness of the plastic feedstock. Different plastics (like PET, PVC, or HDPE) yield different proportions and qualities of oil, gas, and char. Contaminants like food residue, paper, or moisture can negatively affect the efficiency of the process and the quality of the end products.

Making the Right Choice for Your Goal

The value of the pyrolysis products is directly tied to the intended application.

- If your primary focus is energy recovery: The pyrolysis oil and gas are the most valuable outputs, serving as direct substitutes for conventional fuels in heat and power generation.

- If your primary focus is a circular economy: The key is upgrading the pyrolysis oil into a feedstock for creating new plastics or other high-value chemicals, effectively closing the loop on plastic waste.

- If your primary focus is waste volume reduction: The technology excels by converting bulky plastic waste into a smaller volume of dense, usable materials, significantly reducing the burden on landfills.

Ultimately, plastic pyrolysis is a transformative technology that converts a persistent environmental liability into a set of valuable material and energy resources.

Summary Table:

| Product | State | Primary Use |

|---|---|---|

| Pyrolysis Oil | Liquid | Industrial fuel, chemical feedstock |

| Pyrolysis Gas | Gas | On-site heat for the process |

| Solid Char | Solid | Fuel briquettes, sorbent, soil amendment |

Ready to transform your plastic waste into valuable resources? The pyrolysis process is highly dependent on the right equipment to ensure optimal yield and product quality. KINTEK specializes in advanced laboratory equipment and consumables for pyrolysis research and development. Our solutions help you accurately analyze feedstock, optimize process conditions, and characterize the resulting oil, gas, and char. Contact us today (#ContactForm) to learn how our expertise can support your plastic recycling and energy recovery goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs