Properly operating a plate filter press requires a methodical approach that prioritizes preparation, controlled pressure application, and systematic shutdown. The core procedure involves ensuring the filter plates and cloths are correctly installed and aligned, closing the press with the correct hydraulic clamping force, and then gradually feeding the slurry until the chambers are filled with solid cake and the filtrate runs clear.

The key to successful filter press operation is not just following a sequence of steps, but understanding it as a pressure management system. Consistently achieving a dry cake and clear filtrate depends on controlling the feed pressure in response to the cake formation inside the chambers.

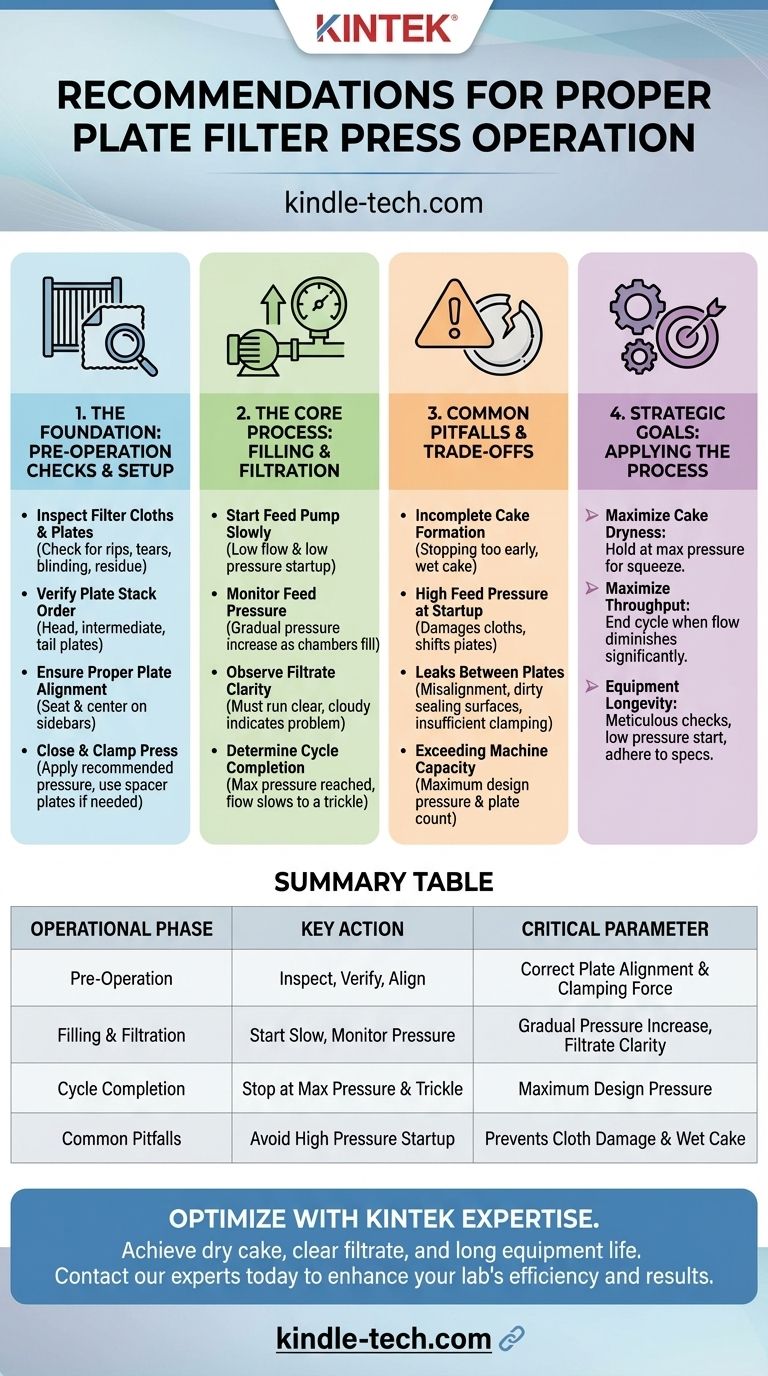

The Foundation: Pre-Operation Checks and Setup

Before starting any filtration cycle, a thorough inspection and proper setup are essential to prevent leaks, equipment damage, and inefficient operation. This stage sets the foundation for the entire process.

Inspecting Filter Cloths and Plates

You must visually inspect each filter cloth for any rips, tears, or excessive blinding (clogging). A damaged cloth is a primary cause of poor filtrate quality.

Also, check the sealing surfaces of the filter plates themselves for any residue or damage that could prevent a proper seal.

Verifying the Plate Stack Order

The plates must be arranged in the correct sequence. This typically involves a head plate, a series of intermediate chamber plates, and a tail plate.

Plates are often numbered to ensure they are returned to the same position and orientation, which helps maintain consistent sealing performance over time.

Ensuring Proper Plate Alignment

As the press is closed, ensure each plate is properly seated and centered on the sidebars. Misalignment is a major cause of leaks and can put immense stress on the plates, potentially causing them to crack under pressure.

Closing and Clamping the Press

Use the hydraulic system to close the plate stack. Apply the manufacturer-recommended clamping pressure to seal the pack.

Insufficient pressure will cause leaks. Excessive pressure can damage the plates. If you are running a batch with fewer plates than the press is designed for, you may need to use spacer plates to ensure the hydraulic cylinder can apply the correct force without over-extending.

The Core Process: Filling and Filtration

This phase is where the separation of solids from liquids occurs. Careful monitoring is critical to achieving the desired outcome.

Starting the Feed Pump

Begin feeding the slurry into the press using a low flow rate and low pressure. A sudden high-pressure surge can slam into the empty filter cloths, causing damage and preventing proper cake formation.

Monitoring Feed Pressure

The feed pressure will be low at the start of the cycle and will gradually increase as the chambers fill with solids and the cake becomes denser. This pressure rise is the primary indicator of cycle progress.

Observing the Filtrate Clarity

The liquid exiting the press, known as the filtrate, should run clear. If the filtrate is cloudy, it immediately signals a problem, such as a torn filter cloth or a poor seal between plates.

Determining Cycle Completion

A filtration cycle is complete when the feed pressure reaches the pre-set maximum and the flow of filtrate slows to a trickle. This indicates the chambers are packed with solids and no more liquid can be efficiently removed.

Understanding the Trade-offs and Common Pitfalls

Avoiding common mistakes is crucial for both the efficiency of the filtration process and the longevity of the equipment.

Incomplete Cake Formation

Stopping the feed cycle too early, before pressure has fully built, will result in a wet, sloppy cake that is difficult to handle and represents poor dewatering performance.

High Feed Pressure at Startup

Introducing slurry at high pressure into an empty press is one of the most common operational errors. This can damage cloths, shift plates, and prevent a uniform cake from forming across the filter surface.

Leaks Between Plates

Leaks are almost always a symptom of an issue during setup. The most common causes are misaligned plates, dirty sealing surfaces, a damaged filter cloth gasket, or insufficient hydraulic clamping pressure.

Exceeding Machine Capacity

Every press has a maximum design pressure and a defined number of plates it can safely operate with. Attempting to add more plates than specified can compromise the structural integrity of the press frame.

How to Apply This to Your Goal

Your operational focus will shift slightly depending on the primary objective of your dewatering process.

- If your primary focus is maximizing cake dryness: Allow the feed pressure to reach its maximum setpoint and hold it there for a designated period to squeeze out as much residual moisture as possible.

- If your primary focus is maximizing throughput: End the cycle as soon as the filtrate flow significantly diminishes, even if maximum pressure hasn't been held for long, to begin the next cycle sooner.

- If your primary focus is equipment longevity: Pay meticulous attention to pre-operation checks, always start the feed at low pressure, and never exceed the manufacturer's recommended clamping and feed pressures.

Mastering a systematic and observant operational routine is the most effective way to ensure reliable and efficient filter press performance.

Summary Table:

| Operational Phase | Key Action | Critical Parameter |

|---|---|---|

| Pre-Operation | Inspect cloths & plates, verify stack order | Correct plate alignment and clamping force |

| Filling & Filtration | Start feed pump slowly, monitor pressure | Gradual feed pressure increase, filtrate clarity |

| Cycle Completion | Stop when pressure maxes and flow trickles | Maximum design pressure |

| Common Pitfalls | Avoid high pressure at startup, ensure complete cake formation | Prevents cloth damage and wet cake |

Optimize your dewatering process with KINTEK's expertise.

Proper filter press operation is key to achieving dry cake, clear filtrate, and long equipment life. Whether your goal is maximizing throughput, cake dryness, or equipment longevity, the right approach and reliable equipment are essential.

KINTEK specializes in lab equipment and consumables, serving laboratory needs with high-quality filtration solutions and expert support. Let our team help you select the right filter press and operational parameters for your specific application.

Contact our experts today to discuss your filtration challenges and discover how we can enhance your lab's efficiency and results.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System