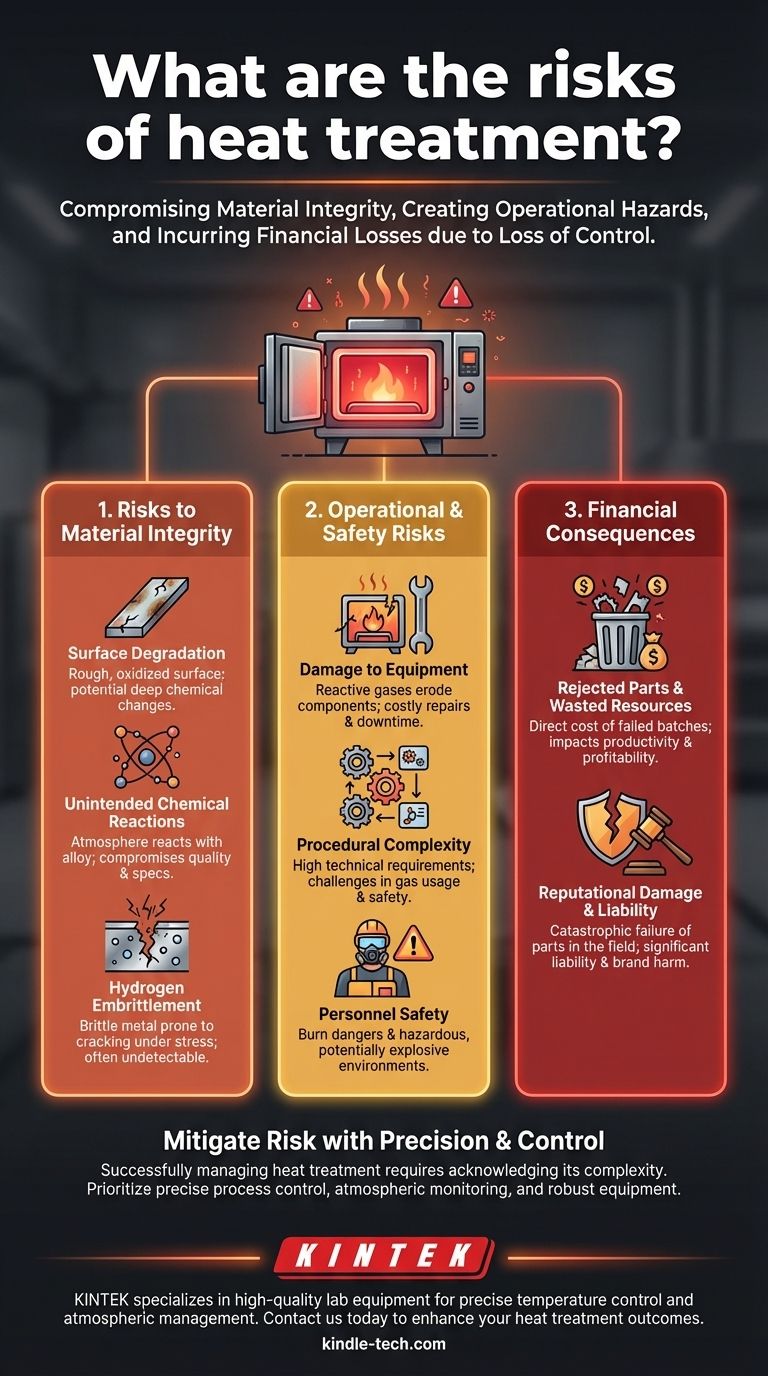

The primary risks of heat treatment fall into three categories: compromising the integrity of the material itself, creating operational hazards for equipment and personnel, and incurring significant financial losses from failed parts. While heat treatment is a powerful tool for enhancing the physical properties of materials like steel, an improperly controlled process can lead to surface degradation, chemical changes, and even catastrophic structural failure.

The core danger of any heat treatment process is a loss of control. Whether it's an improperly managed atmosphere or an incorrect temperature profile, deviation from precise parameters is what transforms a beneficial process into a source of material failure and operational risk.

The Three Categories of Heat Treatment Risk

Heat treatment is not a single process but a range of techniques, each with a unique risk profile. The most significant dangers often arise when using controlled atmospheres, which are necessary for achieving specific material properties but introduce added complexity.

Category 1: Risks to Material Integrity

The entire purpose of heat treatment is to improve a material, but a flawed process can achieve the exact opposite, introducing new and often hidden weaknesses.

Surface Degradation

An improperly controlled atmosphere can result in a rough, non-bright, and oxidized surface on the workpiece. This not only affects the aesthetic quality but can also be an indicator of more serious chemical changes beneath the surface.

Unintended Chemical Reactions

The atmosphere inside a heat treatment furnace can react with the metal alloy. This can compromise its quality and performance, leading to a part that does not meet its required engineering specifications.

Hydrogen Embrittlement

A specific and severe risk for certain types of steel is hydrogen embrittlement. When treated in an atmosphere with a high hydrogen content, the metal can become brittle and prone to cracking under stress, a dangerous and often undetectable flaw.

Category 2: Operational and Safety Risks

The equipment and environments involved in heat treatment present their own set of challenges that require significant expertise and investment to manage.

Damage to Equipment

The reactive gases used in controlled atmospheres can cause erosion and damage to furnace components, particularly the electric heating elements. An uncontrolled reaction can lead to costly repairs and significant downtime.

Procedural Complexity

Controlled atmosphere systems are complex. They demand a large initial investment, have high operating technical requirements, and present challenges in gas usage, safety protocols, and gas recovery processing.

Personnel Safety

The most immediate risk is to the people operating the equipment. Beyond the obvious danger of contact burns from extreme heat, an improperly managed furnace atmosphere can create a hazardous or even explosive environment, posing a direct threat of serious injury.

Category 3: The Financial Consequences of Failure

When heat treatment goes wrong, the financial impact can extend far beyond the cost of a single part.

Rejected Parts and Wasted Resources

The most direct cost is the loss of the part itself. A single failed batch represents a complete waste of materials, energy, and time, directly impacting productivity and profitability.

Reputational Damage and Liability

The most dangerous scenario occurs when a weakened part passes inspection and is used by a customer. The failure of such a component in the field can have catastrophic consequences, leading to significant financial liability and irreparable damage to your company's reputation.

Understanding the Trade-offs

The decision to use heat treatment, especially with a controlled atmosphere, is a balancing act. The benefits of increased strength, durability, and specific mechanical properties must be weighed against the inherent risks.

The Myth of a "Set and Forget" Process

Heat treatment is not a simple automated task. It requires constant monitoring and deep technical expertise to ensure the atmosphere and temperature remain within precise tolerances throughout the cycle.

The Atmosphere Control Dilemma

While a controlled atmosphere is essential for preventing oxidation and achieving superior results, it is also the source of the greatest complexity and risk. The choice to use one requires a commitment to investing in the right equipment and highly skilled operators.

Material and Process Suitability

Not all materials or parts are suitable for every type of heat treatment. Attempting to treat an incompatible alloy in a specific atmosphere can guarantee failure, making material science knowledge a critical prerequisite.

How to Mitigate Risk for Your Project

Your strategy for managing these risks depends entirely on your primary goal and your tolerance for complexity and investment.

- If your primary focus is achieving maximum material performance: Invest heavily in precise process control, real-time atmospheric monitoring, and rigorous post-treatment testing to prevent chemical and structural flaws.

- If your primary focus is operational safety and cost-efficiency: Prioritize robust, well-maintained equipment, comprehensive operator training, and a clear understanding of the high upfront and ongoing costs associated with advanced heat treatment.

- If you are dealing with critical, high-stress components: Implement redundant quality checks and non-destructive testing methods specifically designed to detect issues like hydrogen embrittlement before a part ever leaves your facility.

Ultimately, successfully managing the risks of heat treatment comes from acknowledging its complexity and treating it as the precise engineering discipline it is.

Summary Table:

| Risk Category | Key Dangers |

|---|---|

| Material Integrity | Surface degradation, unintended chemical reactions, hydrogen embrittlement |

| Operational Safety | Equipment damage, procedural complexity, personnel injury risks |

| Financial Impact | Part rejection, wasted resources, reputational damage, liability |

Ensure your heat treatment process is safe and effective. KINTEK specializes in high-quality lab equipment and consumables, providing reliable solutions for precise temperature control and atmospheric management. Our expertise helps you mitigate risks, protect your materials, and maintain operational safety. Contact us today to discuss how we can support your laboratory's specific needs and enhance your heat treatment outcomes.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What are the different types of heat treatment process for steel? Tailor Strength, Hardness & Toughness

- What are the four types of heat treating processes? Master Annealing, Normalizing, Hardening, and Tempering

- Why do you heat treat in a vacuum? Achieve Perfect Surface Finish and Material Integrity

- What are the five basic heat treatment processes of metals? Master Annealing, Hardening & More

- What is the process of vacuum quenching? Achieve Superior Hardness with a Pristine Surface Finish