At its core, a hydraulic press poses significant risks stemming from the immense, controlled force it generates. The primary dangers involve catastrophic mechanical failure under pressure, hazards from the hydraulic fluid itself, and critical errors in operation that can lead to severe injury or machine damage.

The greatest strength of a hydraulic press—its ability to generate extreme force—is also the source of its greatest risks. Effectively managing these risks requires understanding not only the immediate physical dangers but also the hidden operational and maintenance liabilities.

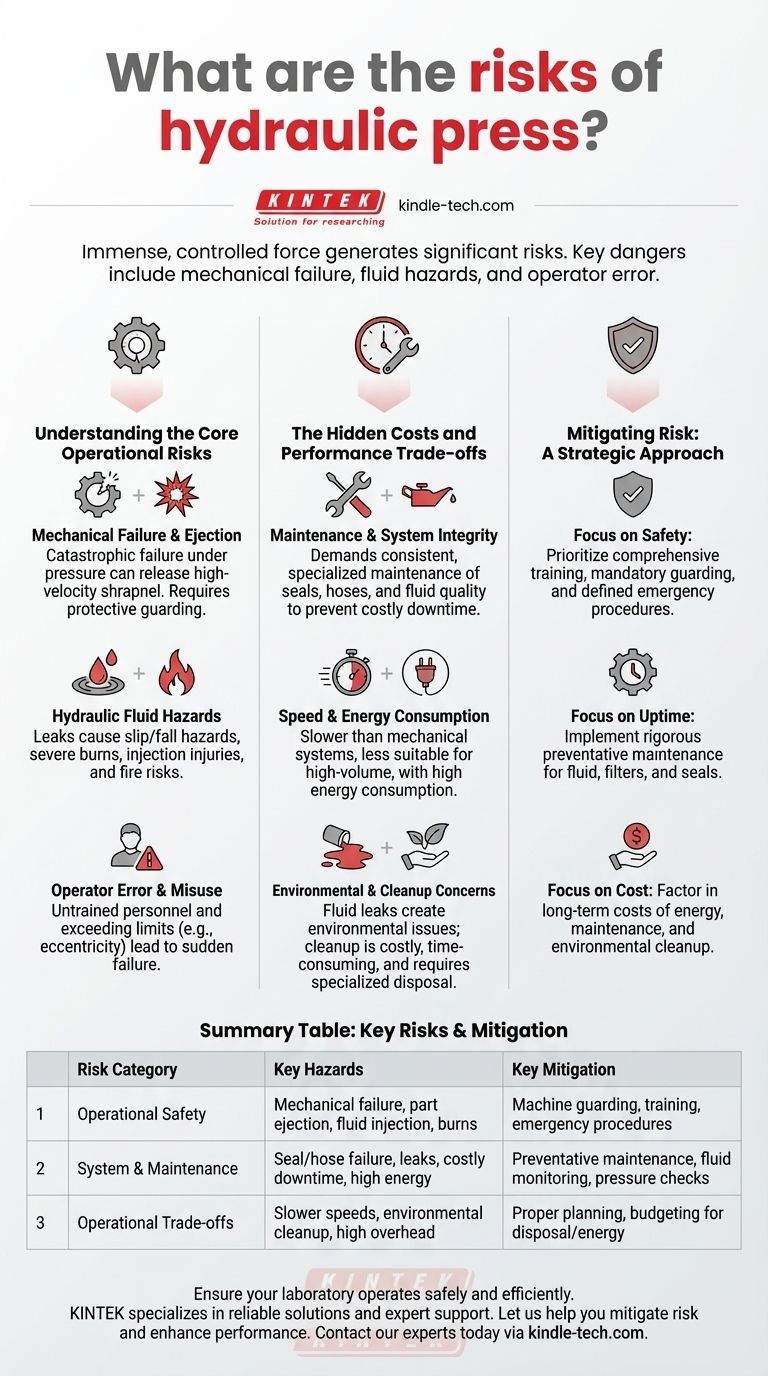

Understanding the Core Operational Risks

The most severe risks are those that threaten the immediate safety of the operator and anyone in the vicinity. These are tied directly to the machine's function and the energy it contains.

Mechanical Failure and Ejection

A hydraulic press works by pressurizing a fluid to generate immense compressive force. If a component like a cylinder, seal, or even the workpiece itself fails, this stored energy can be released violently.

This can result in high-velocity ejection of shrapnel, metal parts, or shattered tooling. Safety features like 10-gauge steel hoods and clear polycarbonate splash doors exist specifically to contain these types of catastrophic failures.

Hydraulic Fluid Hazards

The hydraulic fluid is the lifeblood of the press, but it also presents multiple risks.

First, leaks are a constant concern. A small leak can create a serious slip-and-fall hazard. A major line rupture can spray hot, high-pressure fluid, causing severe burns and injection injuries.

Second, some hydraulic fluids are flammable. If a leak occurs near an ignition source, it can result in a dangerous fire.

Operator Error and Misuse

The machine is only as safe as its operator. Untrained personnel are a significant liability, as they may not recognize the signs of a developing problem.

Exceeding the machine's stated limits, such as the maximum limit of eccentricity (off-center loading), can place asymmetrical stress on the components, leading to premature wear and sudden failure. Likewise, failing to follow proper shutdown procedures can leave the system in an unsafe state.

The Hidden Costs and Performance Trade-offs

Beyond immediate safety, several operational risks and trade-offs can impact efficiency, cost, and long-term viability. These factors must be weighed against the machine's benefits.

Maintenance and System Integrity

While the mechanical design of a press can be simple, its hydraulic system demands consistent and specialized maintenance. This creates a seeming contradiction: the press is both durable and high-maintenance.

The reality is that seals, hoses, and fluid quality must be constantly monitored. A failure to replace aging seals or filter the hydraulic fluid can lead to leaks, loss of pressure, and costly downtime, negating the machine's inherent durability.

Speed and Energy Consumption

Hydraulic presses are not known for speed. The process of building and releasing hydraulic pressure is inherently slower than purely mechanical systems. This makes them less suitable for high-volume, rapid-cycle manufacturing.

Furthermore, these systems can have high energy consumption, as a powerful motor is required to run the pump that pressurizes the fluid, even during idle periods in some designs.

Environmental and Cleanup Concerns

Hydraulic fluid leaks are not just a safety issue; they are an environmental one. Disposing of used or spilled fluid must be done in accordance with regulations.

Cleanup from a significant leak is time-consuming and costly, involving not just labor but also specialized absorbent materials and disposal fees. This contributes to the machine's total carbon footprint and operational overhead.

Mitigating Risk: A Strategic Approach

Understanding the risks is the first step toward controlling them. Your strategy for using a hydraulic press should be aligned with your primary operational goals.

- If your primary focus is operator safety: Prioritize comprehensive training, mandatory use of machine guarding, and clearly defined emergency procedures for leaks or mechanical noise.

- If your primary focus is operational uptime: Implement a rigorous, preventative maintenance schedule for hydraulic fluid, filters, and seals to prevent unexpected downtime.

- If your primary focus is cost-effectiveness: Factor in the long-term costs of high energy consumption, specialized maintenance, and potential environmental cleanup, not just the initial purchase price.

By respecting the inherent power and managing its associated risks, you can effectively harness the capabilities of a hydraulic press.

Summary Table:

| Risk Category | Key Hazards | Key Mitigation Strategies |

|---|---|---|

| Operational Safety | Mechanical failure, part ejection, fluid injection, burns | Machine guarding, comprehensive operator training, emergency procedures |

| System & Maintenance | Seal/hose failure, leaks, costly downtime, high energy use | Preventative maintenance schedules, fluid monitoring, pressure checks |

| Operational Trade-offs | Slower cycle speeds, environmental cleanup, high overhead | Proper planning for volume, budgeting for disposal and energy costs |

Ensure your laboratory operates safely and efficiently. The risks associated with hydraulic presses are significant but manageable with the right equipment and expertise. KINTEK specializes in lab equipment and consumables, serving laboratory needs with reliable solutions and expert support.

Let us help you mitigate risk and enhance performance. Contact our experts today via our secure form to discuss your specific requirements and find the perfect hydraulic press solution for your lab.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Heat Press Machine

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy