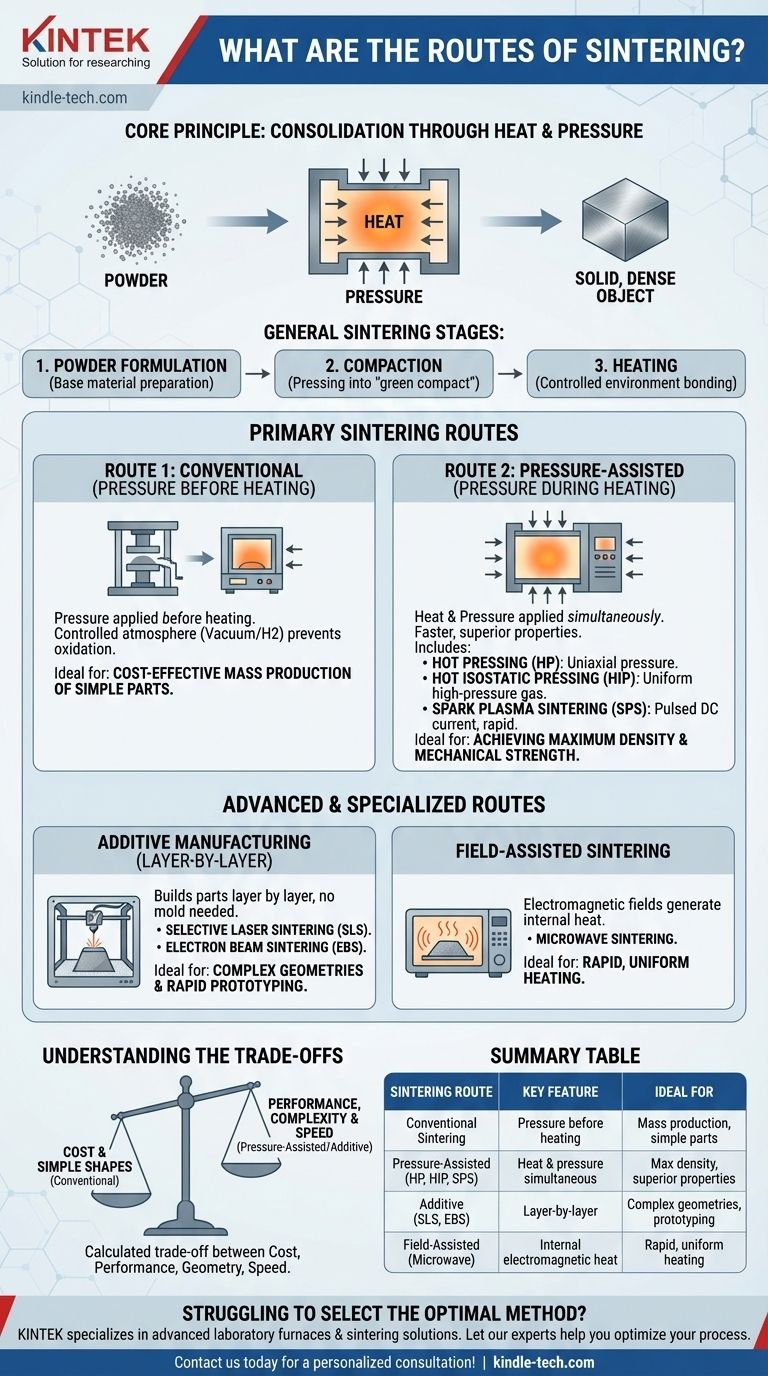

At its core, sintering routes are the distinct methods used to transform a powder into a solid, dense object using heat. These routes are primarily differentiated by how they apply two key variables: heat and pressure. The main categories include conventional sintering where pressure is applied before heating, pressure-assisted sintering where heat and pressure are applied simultaneously, and additive manufacturing techniques that build objects layer by layer.

The choice of a sintering route is not a matter of preference but a critical engineering decision. It involves a calculated trade-off between desired material properties, geometric complexity, production speed, and overall cost.

The Guiding Principle: Consolidation Through Heat and Pressure

Sintering is a thermal treatment for consolidating powdered material into a solid mass. This is accomplished by heating the material to a temperature below its melting point, causing the individual particles to bond and fuse together.

The Two Core Variables

All sintering routes are variations on how to control heat and pressure. Heat provides the energy for atoms to diffuse across particle boundaries, creating strong bonds. Pressure aids this process by forcing particles into closer contact, accelerating densification and helping to eliminate internal voids.

The General Sintering Stages

Regardless of the specific route, the overall process generally involves three stages:

- Powder Formulation: The base material powder is prepared, often mixed with binders or alloying elements.

- Compaction: The powder is pressed into a desired shape, known as a "green compact." This step is sometimes combined with heating.

- Heating: The compact is heated in a controlled environment to induce particle bonding and achieve its final strength and density.

The Primary Sintering Routes

The major distinction between sintering methods is whether pressure is applied before heating or during heating.

Route 1: Conventional (Pressureless) Sintering

This is the most traditional and widely used approach. In this route, the powder is first mechanically pressed into a shape at room temperature (compaction) and then heated in a furnace.

The term "pressureless" can be misleading; it simply means no external pressure is applied during the heating stage. The heating itself is often performed in a controlled atmosphere, such as a vacuum or a specific gas like hydrogen, to prevent oxidation and facilitate the process.

Route 2: Pressure-Assisted Sintering

In these advanced methods, pressure and heat are applied simultaneously. This combination results in faster processing and superior material properties, including higher density and finer grain structures.

- Hot Pressing (HP): Involves simultaneously heating the powder and applying uniaxial pressure (pressure from one direction) within a die.

- Hot Isostatic Pressing (HIP): The material is heated in a vessel while subjected to high-pressure, inert gas from all directions (isostatic pressure). This uniform pressure is highly effective at eliminating internal porosity.

- Spark Plasma Sintering (SPS): A modern, rapid technique where a pulsed DC current is passed through the powder and die. This creates intense localized heat at particle contact points, enabling extremely fast densification at lower overall temperatures.

Advanced & Specialized Sintering Routes

Beyond the primary methods, specialized routes have been developed for unique applications, particularly for complex geometries and novel materials.

Additive Manufacturing (Layer-by-Layer Sintering)

These methods, also known as 3D printing, build parts from the ground up, one layer at a time, directly from a powder bed. This eliminates the need for a pre-formed compact or mold.

- Selective Laser Sintering (SLS): A high-power laser scans across a bed of powder, selectively fusing particles together to create a solid layer.

- Electron Beam Sintering (EBS): Similar to SLS, but uses a focused beam of electrons as the energy source, typically performed in a vacuum.

Field-Assisted Sintering

This category includes methods that use electromagnetic fields to generate heat within the material itself, rather than relying on external furnace elements.

- Microwave Sintering: The material is heated using microwave radiation. This can lead to more uniform and rapid heating compared to conventional furnaces, saving energy and time.

Understanding the Trade-offs

Choosing the right sintering route requires balancing competing priorities. No single method is best for every situation.

Cost vs. Performance

Conventional sintering is generally the most cost-effective method for mass production. Pressure-assisted techniques like HIP and SPS require more sophisticated and expensive equipment but yield superior mechanical properties and near-full density, which is critical for high-performance applications.

Geometric Complexity

Conventional and hot pressing methods are limited to the shapes that can be created in a die. Additive manufacturing routes like SLS excel at producing highly complex, intricate geometries that are impossible to make with traditional methods.

Speed and Throughput

Conventional furnace cycles can take many hours. Spark Plasma Sintering (SPS) and Microwave Sintering are prized for their incredibly short cycle times, often measured in minutes. Additive manufacturing is relatively slow for producing a single part but is ideal for rapid prototyping and custom fabrication.

Selecting the Right Route for Your Application

Your final choice depends entirely on your project's end goal.

- If your primary focus is cost-effective mass production of simple parts: Conventional sintering in a controlled-atmosphere furnace is the industry standard.

- If your primary focus is achieving maximum density and mechanical strength for critical components: A pressure-assisted route like Hot Isostatic Pressing (HIP) or Spark Plasma Sintering (SPS) is necessary.

- If your primary focus is creating a prototype or a final part with complex internal channels and unique geometry: An additive manufacturing route like Selective Laser Sintering (SLS) is the only viable option.

Ultimately, the optimal sintering route is the one that best aligns your material requirements with your manufacturing objectives.

Summary Table:

| Sintering Route | Key Feature | Ideal For |

|---|---|---|

| Conventional Sintering | Pressure applied before heating | Cost-effective mass production of simple parts |

| Pressure-Assisted (HP, HIP, SPS) | Heat and pressure applied simultaneously | Achieving maximum density and superior mechanical properties |

| Additive (SLS, EBS) | Layer-by-layer fabrication from a powder bed | Complex geometries and rapid prototyping |

| Field-Assisted (Microwave) | Internal heating via electromagnetic fields | Rapid, uniform heating cycles |

Struggling to select the optimal sintering method for your materials? The right equipment is critical to achieving your target density, mechanical properties, and production efficiency. KINTEK specializes in providing advanced laboratory furnaces and sintering solutions tailored to your specific needs—from cost-effective conventional furnaces to high-performance Spark Plasma Sintering (SPS) systems. Let our experts help you optimize your process. Contact us today for a personalized consultation!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Can you heat something in a vacuum chamber? Master Precise Thermal Processing in Airless Environments

- What is vacuum sintering? Achieve Unmatched Purity and Performance for Advanced Materials

- What are the methods of brazing heating? Choose the Right Method for Your Production Needs

- Why would you braze instead of solder? For Superior Joint Strength and High-Temperature Performance

- What is the operating temperature of a furnace? From Home Heating to Industrial Processing