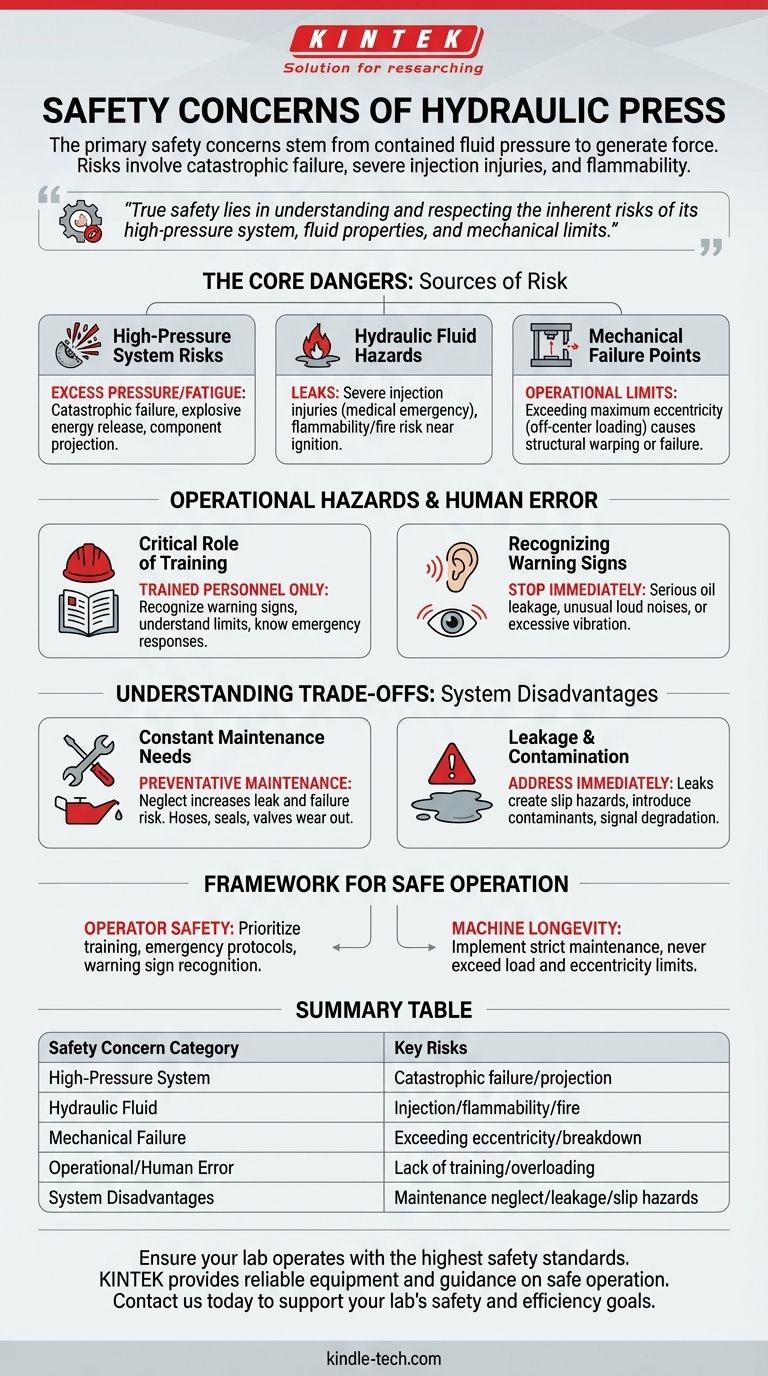

The primary safety concerns with a hydraulic press stem directly from its core operating principle: the use of immense, contained fluid pressure to generate force. The main risks involve catastrophic mechanical failure from over-pressurization, high-pressure fluid leaks that can cause severe injection injuries, and the potential flammability of hydraulic fluids.

A hydraulic press is a powerful tool whose immense force-multiplying capability is also its greatest source of danger. True safety lies not just in following rules, but in understanding and respecting the inherent risks of its high-pressure system, fluid properties, and mechanical limits.

The Core Dangers: Understanding the Sources of Risk

To operate a hydraulic press safely, you must first understand where the dangers originate. The risks are not arbitrary; they are built into the machine's design and physics.

High-Pressure System Risks

A hydraulic system works by pressurizing a fluid to generate extreme force. This contained energy is the primary hazard.

If the press exceeds its designed pressure limits or if a component is fatigued, the result can be a catastrophic failure. This can lead to the explosive release of energy, projecting metal components at high velocity.

Hydraulic Fluid Hazards

The hydraulic fluid itself presents multiple dangers. A pinhole leak in a high-pressure line can eject a nearly invisible stream of fluid capable of penetrating skin and causing a severe fluid injection injury, which is a medical emergency.

Furthermore, some hydraulic fluids are flammable. If a leak occurs near an ignition source, it can result in a fire or explosion.

Mechanical Failure Points

Every press has defined operational limits. One of the most critical is the maximum limit of eccentricity, which refers to off-center loading.

Applying force unevenly puts enormous stress on the press's frame and components. Exceeding this limit can cause the structure to warp or fail, leading to a sudden and dangerous breakdown.

Operational Hazards and Human Error

While the machine has inherent risks, the most significant variable is the operator. Proper procedure and awareness are non-negotiable.

The Critical Role of Training

A hydraulic press must only be operated by trained and authorized personnel.

An untrained operator will not recognize subtle warning signs, understand the machine's limits, or know how to react in an emergency. Training is the single most important safety control.

Recognizing Warning Signs

A press will almost always provide warning signs before a major failure.

Operators must be trained to immediately stop the machine if they notice serious oil leakage, unusual loud noises, or excessive vibration. These symptoms point to underlying problems that must be resolved before work continues.

Exceeding Machine Limits

Never push the machine beyond its stated capacity. This includes the maximum tonnage and any tooling or die limitations.

Overloading the press is a direct path to mechanical failure, risking both the machine and the operator.

Understanding the Trade-offs: Inherent System Disadvantages

Certain disadvantages of hydraulic systems are directly tied to safety and must be managed proactively.

The Constant Need for Maintenance

While some designs are robust, hydraulic systems require consistent maintenance to remain safe. Hoses, seals, and valves wear out over time.

Neglecting this maintenance dramatically increases the risk of leaks and component failure. A rigorous preventative maintenance schedule is a core part of any safety program.

Leakage and Contamination Risks

Even small leaks are a significant concern. They create slip hazards on the floor, introduce contaminants into the hydraulic system (which can cause component failure), and signal the degradation of seals or fittings.

All leaks, no matter how minor, should be addressed immediately.

A Framework for Safe Operation

Your approach to hydraulic press safety should be guided by your primary operational goals.

- If your primary focus is operator safety: Prioritize comprehensive training on standard operating procedures, emergency shutdown protocols, and the recognition of warning signs.

- If your primary focus is machine longevity and reliability: Implement a strict preventative maintenance schedule and enforce an absolute rule to never exceed the press's designed load and eccentricity limits.

Ultimately, safety is achieved by treating the hydraulic press with a deep respect for the immense power it commands.

Summary Table:

| Safety Concern Category | Key Risks |

|---|---|

| High-Pressure System | Catastrophic failure, explosive energy release, component projection |

| Hydraulic Fluid | Injection injuries, flammability, fire/explosion risk |

| Mechanical Failure | Exceeding eccentricity limits, frame stress, structural breakdown |

| Operational/Human Error | Lack of training, ignoring warning signs, overloading the press |

| System Disadvantages | Maintenance neglect, leakage, contamination, slip hazards |

Ensure your lab operates with the highest safety standards. KINTEK specializes in providing reliable lab equipment, including hydraulic presses, and consumables tailored to your laboratory needs. Our experts can help you select the right equipment and provide guidance on safe operation and maintenance protocols. Contact us today to discuss how we can support your lab's safety and efficiency goals.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis