The most critical safety precautions for a filter press involve comprehensive operator training, rigorous pre-operation inspections, and constant monitoring for abnormal conditions like leaks or pressure changes. These machines combine high-pressure hydraulics, powerful mechanical forces, and potentially hazardous materials, requiring a systematic approach to safety at all times.

The core principle of filter press safety is not merely following a checklist, but cultivating a deep awareness of its three primary hazards: high-pressure systems (hydraulic and slurry), powerful mechanical pinch points, and potential chemical exposure.

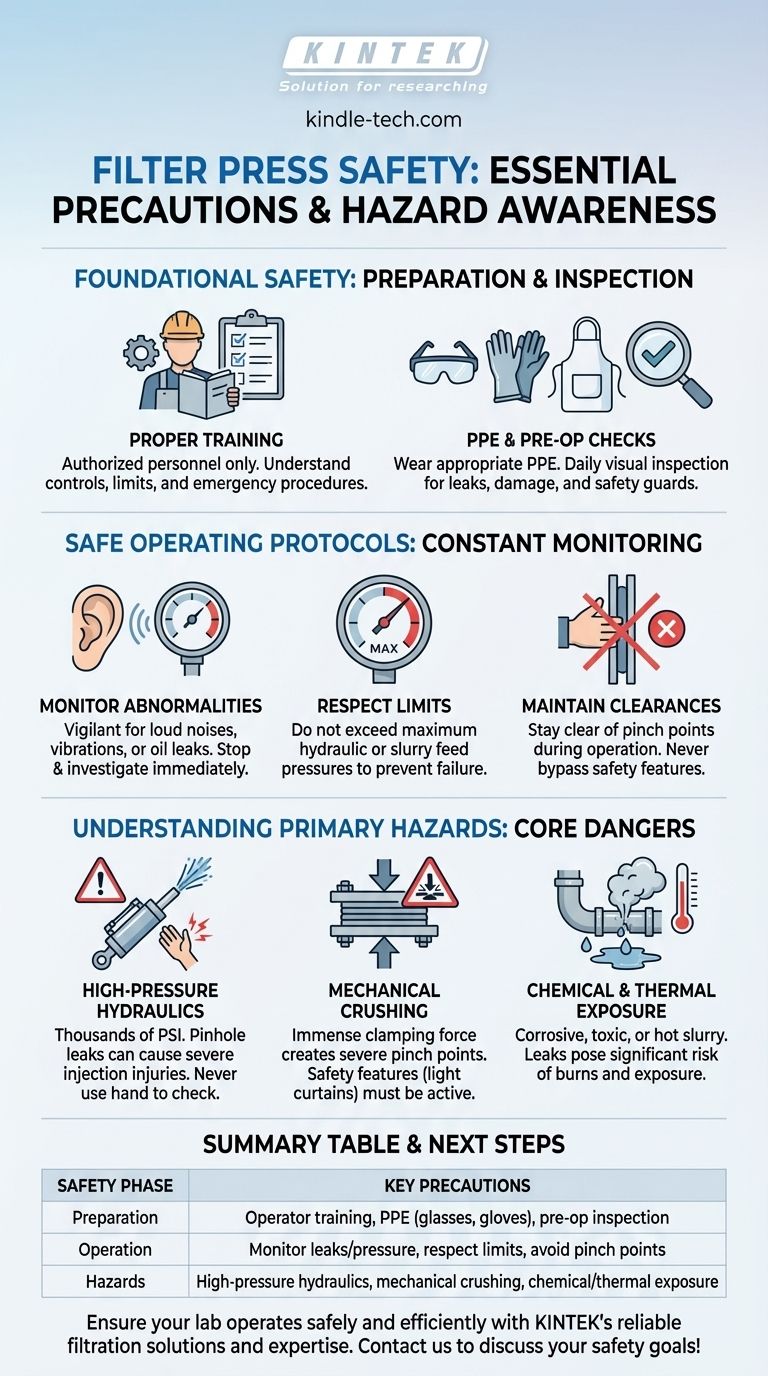

Foundational Safety: Preparation and Inspection

Before the machine is ever started, safety protocols must be in place. This foundational stage prevents the most common causes of incidents.

The Role of Proper Training

Only authorized and formally trained personnel should ever operate a filter press. Effective training goes beyond pushing buttons; it includes understanding the specific machine's controls, its operating limits, and all emergency shutdown procedures.

Personal Protective Equipment (PPE)

The correct PPE is your first line of defense. This typically includes safety glasses with side shields or a full face shield, chemical-resistant gloves appropriate for the slurry, and protective clothing or an apron.

The Pre-Operation Walk-Around

A thorough visual inspection is mandatory before every cycle. Check for any signs of hydraulic oil leaks, worn hoses, damage to the filter plates or cloths, and ensure all safety guards and emergency stops are in place and functional.

Safe Operating Protocols

During the press cycle, operators must remain vigilant, actively monitoring the machine's performance and behavior.

Monitor for Abnormal Conditions

Pay close attention to the machine's sounds and gauges. Any loud or unusual noises from the hydraulic pump, sudden vibrations, or visible oil leakage are clear signals to stop the machine immediately and investigate.

Respect Machine Limits

Never operate the press beyond its designated limits. This includes not exceeding the maximum hydraulic closing pressure or the maximum slurry feed pressure. Over-pressurizing the system can lead to catastrophic failure.

Maintain Safe Clearances

The area between the filter plates is a severe pinch point. Keep all body parts, tools, and clothing far away from the closing mechanism and shifting plates during operation. Never reach into the press while it is powered on.

Understanding the Primary Hazards

A filter press is a powerful piece of industrial equipment. Understanding the specific dangers it presents is key to mitigating them effectively.

High-Pressure Hydraulics

The hydraulic system operates at thousands of PSI. A pinhole leak can eject a stream of fluid at such high velocity that it can penetrate skin, causing a severe injection injury that requires immediate medical attention. Never use your hand to check for leaks.

Mechanical Crushing and Pinch Points

The force generated to clamp the filter plates together is immense, capable of causing serious crushing injuries. Modern presses have safety features like light curtains or two-hand controls; these must never be bypassed.

Chemical and Thermal Exposure

The slurry being processed can be corrosive, toxic, or at a high temperature. A leak between the plates or a ruptured feed line can spray hazardous material over a wide area, posing a significant risk of chemical burns or injury.

Making the Right Choice for Your Goal

Adhering to safety protocols is a non-negotiable aspect of filter press operation. Your role determines your primary area of focus.

- If your primary focus is daily operation: Make the pre-operation inspection and constant monitoring of pressures and sounds an unbreakable habit.

- If your primary focus is supervision: Ensure that all operators are formally trained, that PPE is always available and used, and that a strict maintenance schedule is followed.

- If your primary focus is maintenance: Always implement full Lockout/Tagout (LOTO) procedures to de-energize all power sources before beginning any service.

Ultimately, a proactive safety culture is the most effective tool for preventing incidents and ensuring a safe working environment.

Summary Table:

| Safety Phase | Key Precautions |

|---|---|

| Preparation | Operator training, PPE (safety glasses, gloves), pre-operation inspection |

| Operation | Monitor for leaks/pressure changes, respect pressure limits, avoid pinch points |

| Hazards | High-pressure hydraulics, mechanical crushing, chemical/thermal exposure |

Ensure your lab operates safely and efficiently with the right equipment. KINTEK specializes in reliable lab equipment and consumables, including filtration solutions designed with safety in mind. Our experts can help you select and maintain equipment that meets your laboratory's specific needs. Contact us today to discuss how we can support your lab's safety and performance goals!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System