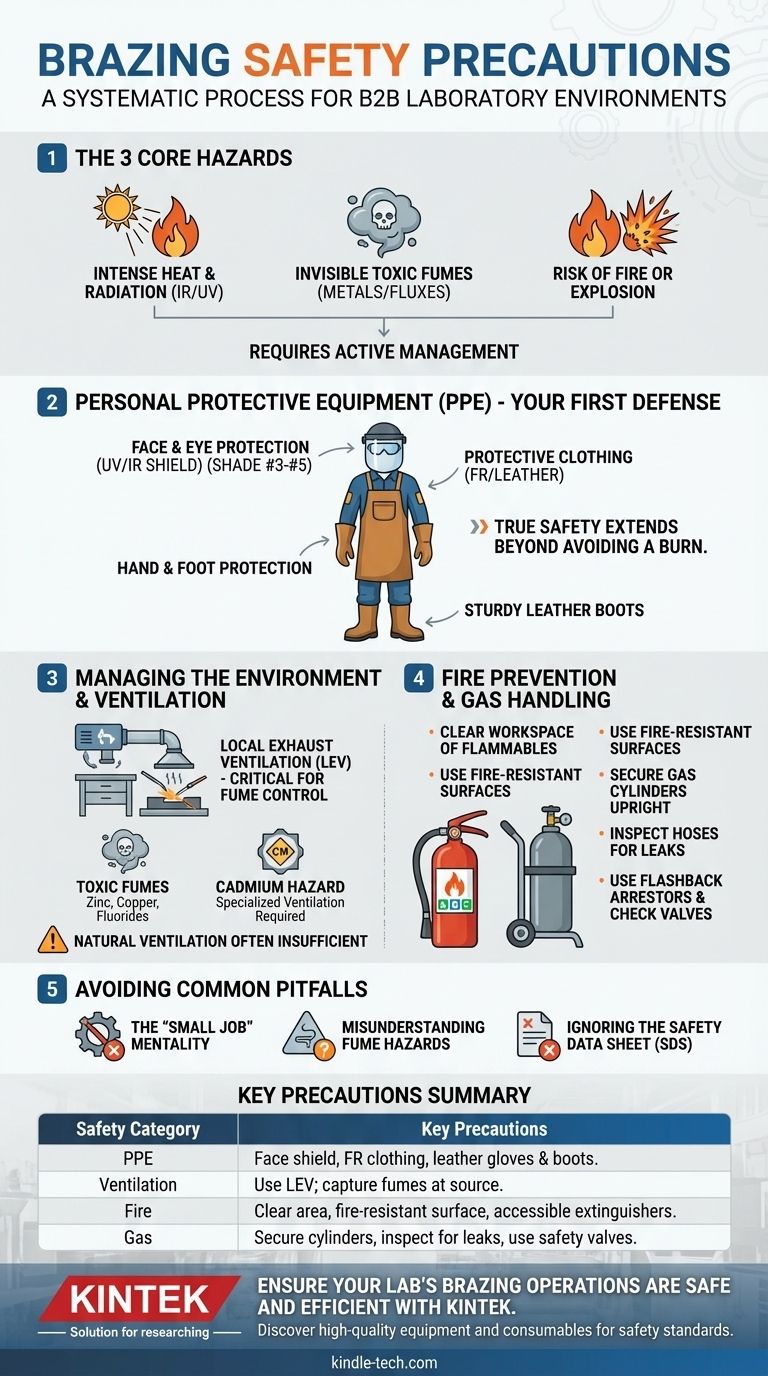

Brazing safety is a systematic process, not a simple checklist. The essential precautions involve using specific personal protective equipment (PPE) for heat and radiation, ensuring robust ventilation to remove toxic fumes, preparing the workspace to prevent fires, and handling gas cylinders and materials with extreme care.

True brazing safety extends beyond simply avoiding a burn. It requires a deep understanding and active management of the three primary hazards: intense heat and radiation, invisible toxic fumes from fluxes and metals, and the constant risk of fire or explosion.

Protecting Yourself: Personal Protective Equipment (PPE)

Your first line of defense is what you wear. Brazing involves significant thermal, infrared (IR), and ultraviolet (UV) radiation hazards, even if the glow doesn't seem as intense as a welding arc.

Eye and Face Protection

You must protect your eyes from spatter and harmful radiation. The hot base metal and filler emit IR and UV light that can cause serious, permanent eye damage.

A full-face shield over safety glasses provides the best protection. Goggles or safety glasses used for brazing should have a minimum shade of #3 to #5, depending on the intensity of the operation.

Protective Clothing

Synthetic materials like polyester or nylon can melt and fuse to your skin when exposed to heat or spatter. Never wear them.

Opt for flame-resistant (FR) clothing, heavy wool, or leather. A leather apron and sleeves are excellent for protecting your torso and arms from heat and molten filler metal.

Hand and Foot Protection

Your hands are closest to the heat source. Always wear dry, gauntlet-style leather gloves to protect your hands and wrists.

Sturdy, closed-toe footwear, preferably leather work boots, is also mandatory to protect against dropped parts or spatter.

Managing the Environment: Ventilation and Fume Control

This is the most frequently overlooked—and one of the most critical—aspects of brazing safety. Heating metals and fluxes releases a complex mixture of fumes and gases that can be highly toxic.

The Dangers of Brazing Fumes

Brazing filler metals can contain zinc, copper, silver, and other elements. Fluxes often contain fluoride compounds. When heated, these materials create metal oxides and fluoride fumes.

Inhaling these fumes can lead to metal fume fever, a flu-like illness, or cause long-term respiratory damage. Fillers containing cadmium (now rare but still present in older stock) are extremely toxic and require specialized ventilation and respiratory protection.

Ventilation is Non-Negotiable

Natural ventilation, such as an open garage door, is rarely sufficient for anything beyond the smallest, most infrequent jobs.

The best practice is Local Exhaust Ventilation (LEV). This uses a capture hood positioned near the work to draw fumes away from your breathing zone before they can spread. For production work, LEV is essential.

Fire Prevention and Emergency Preparedness

You are working with an open flame and materials heated to over 840°F (450°C). The risk of fire is constant and must be proactively managed.

Preparing the Work Area

The brazing area must be completely clear of all flammable materials, including wood, paper, rags, and flammable liquids or aerosols.

Work on a fire-resistant surface like a welding table or fire bricks. Keep a fire extinguisher rated for Class A, B, and C fires within easy reach. If working with combustible metals like magnesium, a Class D extinguisher is required.

Safe Gas Cylinder Handling

Gas cylinders contain immense pressure and flammable fuel. They must always be chained securely in an upright position to a wall or cart.

Before use, inspect all hoses and connections for leaks using a soapy water solution. Always use flashback arrestors and check valves on both the torch and regulator side to prevent a flame from traveling back into the hoses or cylinder.

Understanding the Common Pitfalls

Building a safe habit means recognizing and avoiding common shortcuts and misunderstandings that lead to accidents.

The "It's Just a Small Job" Mentality

Severity of injury is not proportional to the size of the job. A moment of carelessness on a small repair can cause a severe burn, fire, or toxic exposure just as easily as on a large production run. Treat every operation with the same level of respect.

Misunderstanding Fume Hazards

The most dangerous hazards of brazing are often the ones you cannot see. Many toxic fumes are invisible and odorless. Never assume that if you don't see thick smoke, the air is safe to breathe.

Ignoring the Safety Data Sheet (SDS)

Every filler metal and flux comes with a Safety Data Sheet. This document is your most important resource. It details the material's specific hazards, required PPE, and emergency procedures. Reading it is a critical step in your safety preparation.

Making the Right Choice for Your Goal

Your specific safety setup should be scaled to the frequency and nature of your work.

- If your primary focus is occasional hobby use or a single repair: Prioritize a completely clear, fire-safe workspace and full PPE (face shield, leather gloves, FR clothing). Work outdoors or in a space with wide-open doors to maximize natural ventilation.

- If your primary focus is setting up a professional workshop: Invest in a dedicated brazing station with a proper fire-resistant surface and a Local Exhaust Ventilation (LEV) system. Enforce strict PPE and cylinder handling protocols at all times.

- If you are required to use older, cadmium-bearing filler metals: Your absolute priority is respiratory protection. This requires an LEV system coupled with a properly fitted respirator, and you must follow all specific OSHA guidelines for cadmium exposure.

A proactive and informed approach to safety transforms brazing from a dangerous task into a controlled and highly effective process.

Summary Table:

| Safety Category | Key Precautions |

|---|---|

| Personal Protective Equipment (PPE) | Full-face shield over safety glasses (shade #3-#5), flame-resistant clothing, leather gloves, and sturdy boots. |

| Ventilation & Fume Control | Use Local Exhaust Ventilation (LEV) to remove toxic fumes from fluxes and metals; natural ventilation is often insufficient. |

| Fire Prevention | Clear workspace of flammables, use fire-resistant surfaces, and keep appropriate fire extinguishers (Class A, B, C) accessible. |

| Gas Cylinder Handling | Secure cylinders upright, inspect hoses for leaks, and use flashback arrestors and check valves. |

Ensure your lab's brazing operations are safe and efficient with KINTEK.

Brazing requires precision and, most importantly, a commitment to safety. KINTEK specializes in providing high-quality lab equipment and consumables designed to meet rigorous safety standards. Whether you need reliable PPE, advanced fume extraction systems, or durable brazing materials with clear Safety Data Sheets, we have the solutions to protect your team and enhance your workflow.

Don't compromise on safety—contact us today to discuss your specific laboratory needs and discover how KINTEK can support your brazing projects with trusted products and expert guidance.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- Is HVAC brazing or soldering? The Critical Choice for Strong, Leak-Free Systems

- Why Use a Vacuum Annealing Furnace for De-hydrogenation? Isolate Permanent Damage in Hydrogen-Exposed Metals

- What is the process of a vacuum furnace? Achieve Superior Material Purity and Performance

- What is the function of a precision isothermal heating furnace in inducing secondary phase precipitation? Optimize Microstructures

- What happens if proper clearance is not maintained between joints while brazing? Avoid Common Joint Failures

- What is var in metals? A Guide to Vacuum Arc Remelting for Superior Alloys

- What are the factors that control the sintering process? Master Temperature, Time, Pressure & Material

- Is physical vapor deposition safe? Understanding the Engineered Safety of PVD Technology