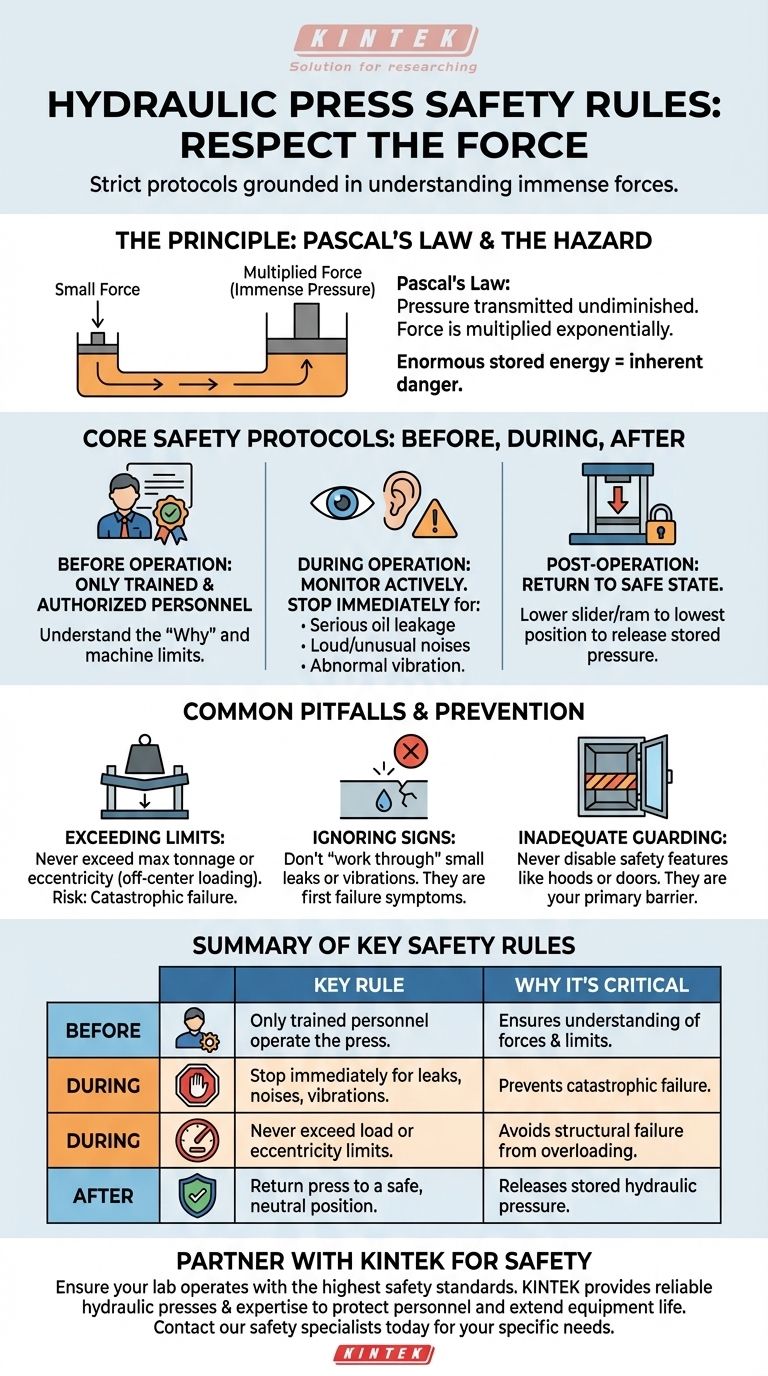

Operating a hydraulic press requires strict adherence to safety protocols grounded in an understanding of the immense forces at play. The most critical rules are ensuring only properly trained personnel operate the machine, immediately stopping work if any abnormalities like oil leaks, unusual noises, or vibrations occur, never exceeding the machine's specified load limits, and returning the press to a safe, neutral position after use.

The core of hydraulic press safety is not merely following a checklist, but respecting the physics. Understanding that the machine multiplies force exponentially via Pascal's Law is the key to recognizing why procedural discipline and machine maintenance are non-negotiable.

The Principle of Force: Why a Press Demands Respect

To operate a press safely, you must first understand how it generates its power. The danger is a direct consequence of its core operating principle.

Pascal's Law in Action

A hydraulic press works on Pascal’s Law, which states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In simple terms, a small amount of force applied to a small piston creates immense pressure in the hydraulic fluid. This pressure then acts on a much larger piston, multiplying the initial force significantly.

The Source of the Hazard

This force multiplication is what makes the press a powerful tool, but it's also what makes it inherently dangerous. The stored energy in the compressed fluid is enormous. A failure in any component can lead to a sudden, catastrophic release of that energy.

Core Safety Protocols: Before, During, and After

A safe operation is a disciplined one. The safety process can be broken down into three distinct phases.

The Operator: The First Line of Defense

The single most important safety rule is that only trained and authorized personnel should ever operate a hydraulic press. Training must cover not only the "how" of operation but the "why" of every safety procedure and the specific limits of the machine.

Monitoring During Operation

The operator must remain vigilant while the press is active. Be alert for any signs of malfunction, including:

- Serious oil leakage

- Loud or unusual noises

- Abnormal vibration

If any of these signs appear, the machine must be stopped immediately. These are indicators of potential mechanical or hydraulic failure.

Post-Operation Procedure

After the work is complete, the machine must be put into a safe state. This typically involves lowering the slider or ram to its lowest position. This action releases any stored hydraulic pressure, making the machine inert and safe for the next user.

Understanding the Common Pitfalls

Many incidents occur not from a single major error, but from a series of seemingly small oversights. Recognizing these common pitfalls is critical for prevention.

Exceeding Machine Limits

Every press has a maximum rated tonnage and a limit for eccentricity (off-center loading). Overloading the press or placing a workpiece off-center creates stress that the machine was not designed to handle, risking catastrophic structural failure.

Ignoring Warning Signs

A small leak or a new vibration can seem minor, but these are often the first symptoms of a developing failure. The pitfall is to "work through it" instead of stopping to diagnose the issue. This habit turns a preventable maintenance issue into a major safety incident.

Inadequate Guarding

Modern presses are equipped with safety features like steel hoods and clear, impact-resistant polycarbonate doors. These are not optional. Never operate a press with safety guards removed or disabled. They are your primary physical barrier against component failure or material expulsion.

Making the Right Choice for Your Goal

Your approach to safety should align with your primary responsibility, whether you are an operator, a manager, or a safety engineer.

- If your primary focus is operator safety: Ensure all training is comprehensive, documented, and regularly refreshed, with a zero-tolerance policy for operating without authorization.

- If your primary focus is machine longevity: Implement a strict preventative maintenance schedule and empower operators to stop work immediately at the first sign of a problem.

- If your primary focus is overall facility safety: Build a program that starts with selecting the correct press for the application and integrates guarding, training, and maintenance into a single, cohesive safety system.

Ultimately, safety with a hydraulic press is a proactive culture, not just a reactive checklist.

Summary Table:

| Safety Phase | Key Rule | Why It's Critical |

|---|---|---|

| Before Operation | Only trained personnel operate the press. | Ensures understanding of immense forces and machine limits. |

| During Operation | Stop immediately for leaks, noises, or vibrations. | Prevents catastrophic failure from developing issues. |

| During Operation | Never exceed load or eccentricity limits. | Avoids structural failure from overloading or off-center stress. |

| After Operation | Return press to a safe, neutral position. | Releases stored hydraulic pressure, making the machine inert. |

Ensure your lab operates with the highest safety standards. KINTEK specializes in providing reliable lab equipment, including hydraulic presses, and the consumables that keep them running safely. Our expertise helps you protect your personnel and extend the life of your equipment. Contact our safety specialists today to discuss your specific needs and find the right solution for your laboratory.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Manual Lab Heat Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

People Also Ask

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis