In metallurgy, quenching is the process of rapid cooling to achieve specific material properties, most notably hardness in steel. The primary techniques involve controlling the cooling rate through different methods and media, including direct, interrupted, selective, and spray quenching, utilizing quenchants like water, brine, oil, or air.

The goal of quenching is not simply to cool a part as fast as possible. It is a precise thermal control process designed to manipulate a metal's internal microstructure, balancing the achievement of high hardness with the critical need to minimize internal stress, distortion, and the risk of cracking.

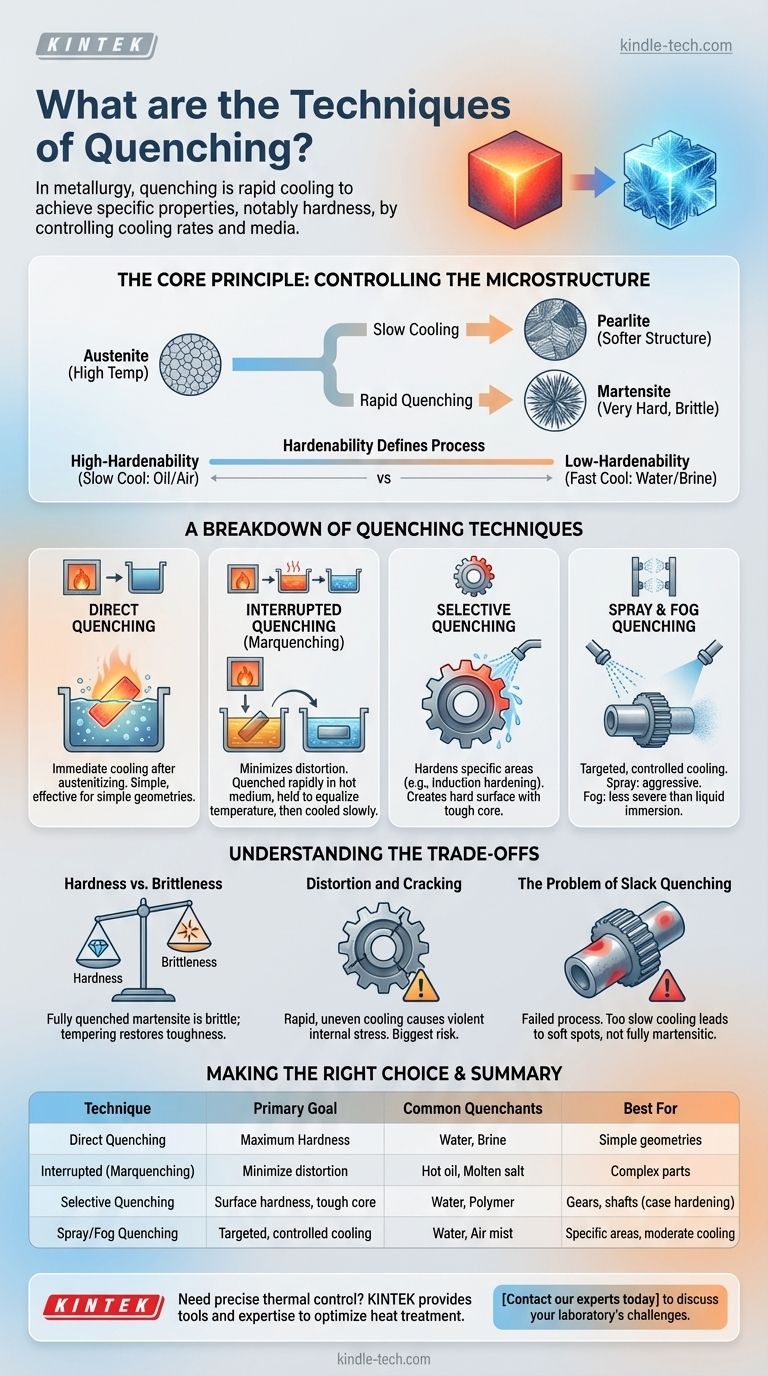

The Core Principle: Controlling the Microstructure

The entire purpose of quenching is to control how the internal crystal structure of a metal, particularly steel, transforms as it cools.

From Austenite to Martensite

When steel is heated to a high temperature (a process called austenitizing), its internal structure changes to a phase called austenite. If cooled slowly, it will transform into softer structures like pearlite.

Quenching is designed to cool the steel so rapidly that the normal transformation is bypassed. This forces the austenite to transform into martensite, a very hard and brittle needle-like structure.

Hardenability Defines the Process

A material's hardenability is its ability to form martensite. High-hardenability steels can be hardened with slower cooling rates (like oil or even air), while low-hardenability steels require a very fast quench (like water or brine) to achieve full hardness.

A Breakdown of Quenching Techniques

Different techniques provide different levels of control over the cooling rate and its uniformity.

Direct Quenching

This is the most straightforward method. The part is cooled in a quenching medium immediately after being removed from the austenitizing furnace. It is simple and effective for parts with simple geometry.

Interrupted Quenching (Marquenching)

This is an advanced technique used to minimize distortion. The part is quenched rapidly in a hot medium (like molten salt or hot oil) to a temperature just above where martensite begins to form.

It is held at this temperature long enough for the entire part to equalize, then cooled slowly through the martensite transformation range. This reduces the thermal shock and internal stresses that cause warping and cracking. Time quenching is a related term referring to this controlled hold time.

Selective Quenching

This technique hardens only specific areas of a part while leaving the core soft and tough. A common example is induction hardening, where only the surface of a gear tooth is heated and then immediately quenched with a spray.

This creates a hard, wear-resistant surface with a ductile core that can absorb shock, and is also known as case hardening.

Spray and Fog Quenching

Instead of full immersion, these techniques apply the quenching medium as a directed spray or a fine mist.

Spray quenching allows for aggressive and targeted cooling. Fog quenching provides a less severe quench than full immersion in a liquid, offering a cooling rate somewhere between a liquid and still air.

Understanding the Trade-offs

Choosing a quenching technique is a matter of balancing competing priorities. The wrong choice can ruin the component.

Hardness vs. Brittleness

The primary trade-off is that the harder the material becomes, the more brittle it is. A fully quenched, martensitic part is often too brittle for practical use and must be tempered (reheated to a lower temperature) to restore some toughness.

Distortion and Cracking

Rapid cooling is a violent process that creates immense internal stress. If the cooling is uneven, different sections of the part shrink at different rates, leading to warping (distortion) or even cracking. This is the single biggest risk in any quenching operation.

The Problem of Slack Quenching

Slack quenching is not a desired technique but a term for a failed process. It occurs when the cooling rate is too slow to fully transform the structure into martensite, resulting in soft spots and a part that does not meet its hardness specification.

Making the Right Choice for Your Goal

Your choice of quenching method and medium depends entirely on the material and the desired final properties of the component.

- If your primary focus is maximum hardness on a simple part: Use direct quenching in a medium with high cooling power, like water or brine, but be prepared for high distortion risk and the absolute need for tempering.

- If your primary focus is minimizing distortion on a complex part: Use interrupted quenching (marquenching) to equalize temperature before the final transformation, drastically reducing internal stress.

- If your primary focus is surface wear resistance with a tough core: Use selective quenching, such as induction or flame hardening, to create a hard case on a specific area.

- If your primary focus is hardening a high-hardenability tool steel: A slow medium like oil or even air quenching is sufficient and inherently safer, producing far less internal stress.

Ultimately, successful quenching is about selecting the slowest possible cooling rate that still achieves the necessary hardness for your specific application.

Summary Table:

| Technique | Primary Goal | Common Quenchants | Best For |

|---|---|---|---|

| Direct Quenching | Maximum hardness | Water, Brine | Simple geometries |

| Interrupted (Marquenching) | Minimize distortion | Hot oil, Molten salt | Complex parts |

| Selective Quenching | Surface hardness, tough core | Water, Polymer | Gears, shafts (case hardening) |

| Spray/Fog Quenching | Targeted, controlled cooling | Water, Air mist | Specific areas, moderate cooling |

Need precise thermal control for your materials? The right quenching technique is critical for achieving the perfect balance of hardness, durability, and dimensional stability in your components. KINTEK specializes in lab equipment and consumables for metallurgical processes, providing the tools and expertise to optimize your heat treatment results.

Contact our experts today to discuss how we can support your laboratory's quenching and heat treatment challenges.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control