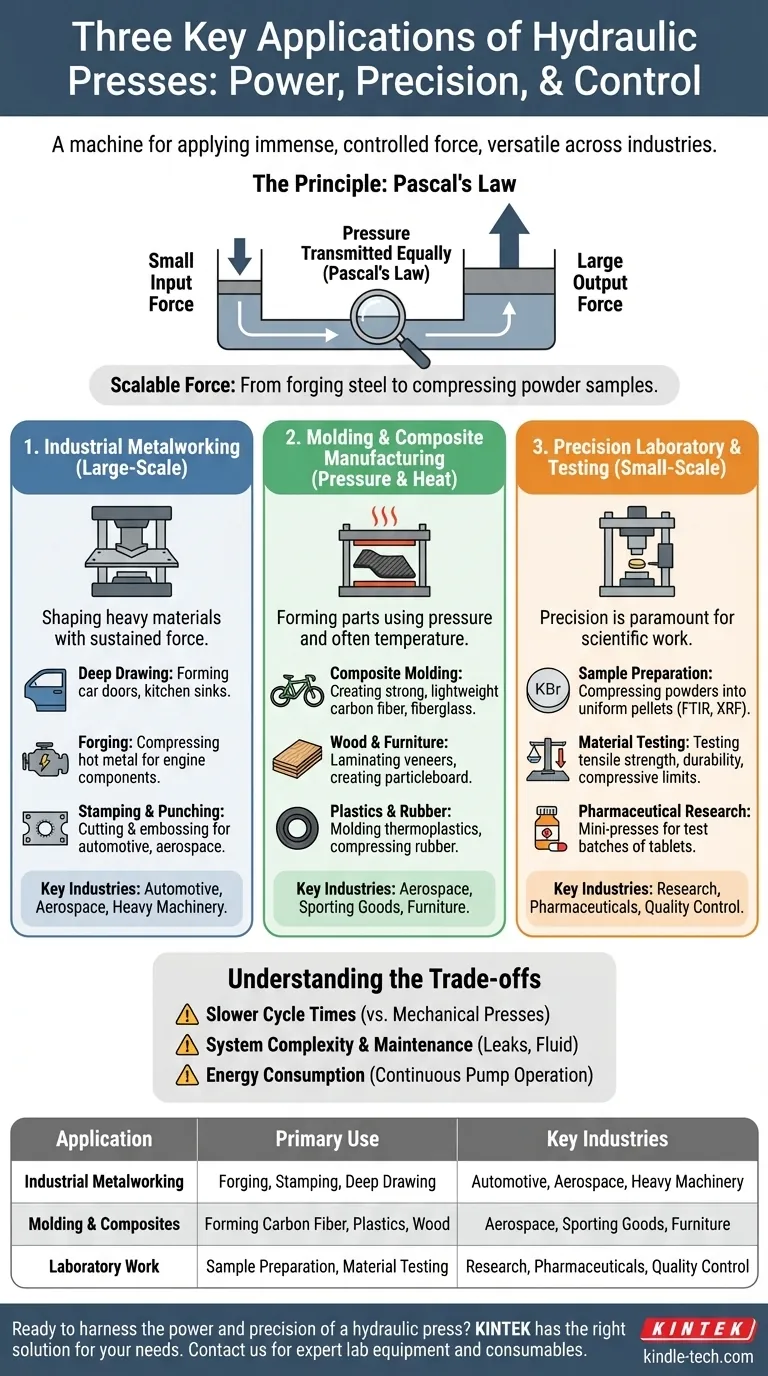

At its core, a hydraulic press is a machine for applying immense, controlled force. While its applications are vast, three primary examples showcase its versatility: industrial metal forming, such as stamping car body panels; material molding, like creating carbon fiber components or wooden furniture; and precision laboratory work, where it is used to prepare small samples for scientific analysis.

The true value of the hydraulic press is not just its power, but its scalability. The same physical principle—Pascal's Law—that allows a machine to forge steel for an airplane also allows a scientist to precisely compress a tiny powder sample for spectroscopic analysis.

The Principle: How Force is Multiplied

Before exploring its uses, it is critical to understand why a hydraulic press is so effective. Its operation is based on a fundamental concept in fluid mechanics.

The Power of Pascal's Law

A hydraulic press uses two connected cylinders of different sizes, filled with an incompressible fluid like oil. When a small force is applied to the small piston, it generates pressure throughout the fluid.

According to Pascal's Law, this pressure is transmitted equally in all directions. Because the second piston has a much larger surface area, the same pressure exerts a proportionally larger total force. This is how a small input force is multiplied into a massive output force.

The Advantage of Control

Unlike a mechanical press that delivers force in a rapid stroke, a hydraulic press can apply and maintain a constant force for an extended period. The pressure and ram speed are highly controllable, which is essential for many modern manufacturing and scientific processes.

Application Deep Dive: From Factory to Laboratory

The ability to deliver scalable, controlled force makes the hydraulic press a cornerstone tool across vastly different industries.

1. Large-Scale Industrial Metalworking

This is the classic image of a hydraulic press: a massive machine shaping heavy materials. Its ability to deliver sustained force is ideal for deforming large metal sheets without fracturing them.

Key operations include:

- Deep Drawing: Forming flat metal sheets into complex shapes like car doors or kitchen sinks.

- Forging: Compressing hot metal billets to create extremely strong parts like engine components or industrial tools.

- Stamping & Punching: Cutting or embossing shapes into metal sheets, common in automotive and aerospace manufacturing.

2. Molding and Composite Manufacturing

Hydraulic presses are essential for forming parts from materials that need both pressure and temperature to cure or take shape. Hydraulic hot presses integrate heating elements into the platens.

Common uses are:

- Composite Molding: Creating strong, lightweight parts from materials like carbon fiber or fiberglass for aerospace, automotive, and sporting goods.

- Wood and Furniture Production: A hot press is used to laminate wood veneers, create particleboard, and apply decorative surfaces to furniture panels.

- Plastics and Rubber: Molding thermoplastics and compressing rubber into specific shapes and densities.

3. Precision Laboratory and Testing Work

On a much smaller scale, the hydraulic press is a vital tool in scientific and quality control labs. Here, precision is more important than raw power.

Frequent applications include:

- Sample Preparation: Compressing powders into uniform pellets (e.g., KBr pellets for FTIR spectroscopy or sample discs for XRF analysis) to ensure consistent analytical results.

- Material Testing: Applying a precise, controlled force to test the tensile strength, durability, or compressive limits of a material.

- Pharmaceutical Research: Portable mini-presses are used in labs to create test batches of tablets or prepare materials for analysis.

Understanding the Trade-offs

Despite its versatility, the hydraulic press is not the solution for every task. Acknowledging its limitations is key to making an informed decision.

Slower Cycle Times

Compared to mechanical presses, hydraulic presses generally have slower cycle times. The process of building and releasing hydraulic pressure takes longer than the purely mechanical stroke of a flywheel-driven press. This makes them less suitable for high-speed, high-volume production of small items.

System Complexity and Maintenance

Hydraulic systems involve pumps, valves, hoses, seals, and hydraulic fluid. This complexity introduces more potential points of failure, with fluid leaks being a common maintenance concern. The fluid itself must also be kept clean and replaced periodically.

Energy Consumption

In many designs, the hydraulic pump runs continuously to maintain system pressure, even when the press is idle between cycles. This can lead to higher overall energy consumption compared to mechanical presses that only draw significant power during the actual stroke.

Making the Right Choice for Your Goal

The best type of press is determined entirely by the task you need to accomplish.

- If your primary focus is heavy-duty manufacturing: You require a large-tonnage press designed for operations like forging, stamping, and deep drawing where sustained force is paramount.

- If your primary focus is creating composite or molded parts: A hydraulic hot press with precise temperature and pressure regulation is essential for working with materials like carbon fiber, plastics, or wood veneers.

- If your primary focus is scientific research or quality control: A smaller laboratory or mini-press provides the repeatable, controlled compression needed for sample preparation and material testing.

Ultimately, the hydraulic press is a master tool for translating controlled fluid pressure into tangible, forceful results.

Summary Table:

| Application | Primary Use | Key Industries |

|---|---|---|

| Industrial Metalworking | Forging, Stamping, Deep Drawing | Automotive, Aerospace, Heavy Machinery |

| Molding & Composites | Forming Carbon Fiber, Plastics, Wood | Aerospace, Sporting Goods, Furniture |

| Laboratory Work | Sample Preparation, Material Testing | Research, Pharmaceuticals, Quality Control |

Ready to harness the power and precision of a hydraulic press for your specific needs? Whether you're forging large metal components, molding advanced composites, or preparing precise laboratory samples, KINTEK has the right solution. Our expertise in lab equipment and consumables ensures you get a press that delivers the controlled force and reliability your work demands. Contact us today to find the perfect hydraulic press for your application!

Visual Guide

Related Products

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What technical conditions does a heated hydraulic press provide for PEO batteries? Optimize Solid-State Interfaces

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating

- How does a heated laboratory hydraulic press facilitate densification in CSP? Optimize Mg-doped NASICON Sintering

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing