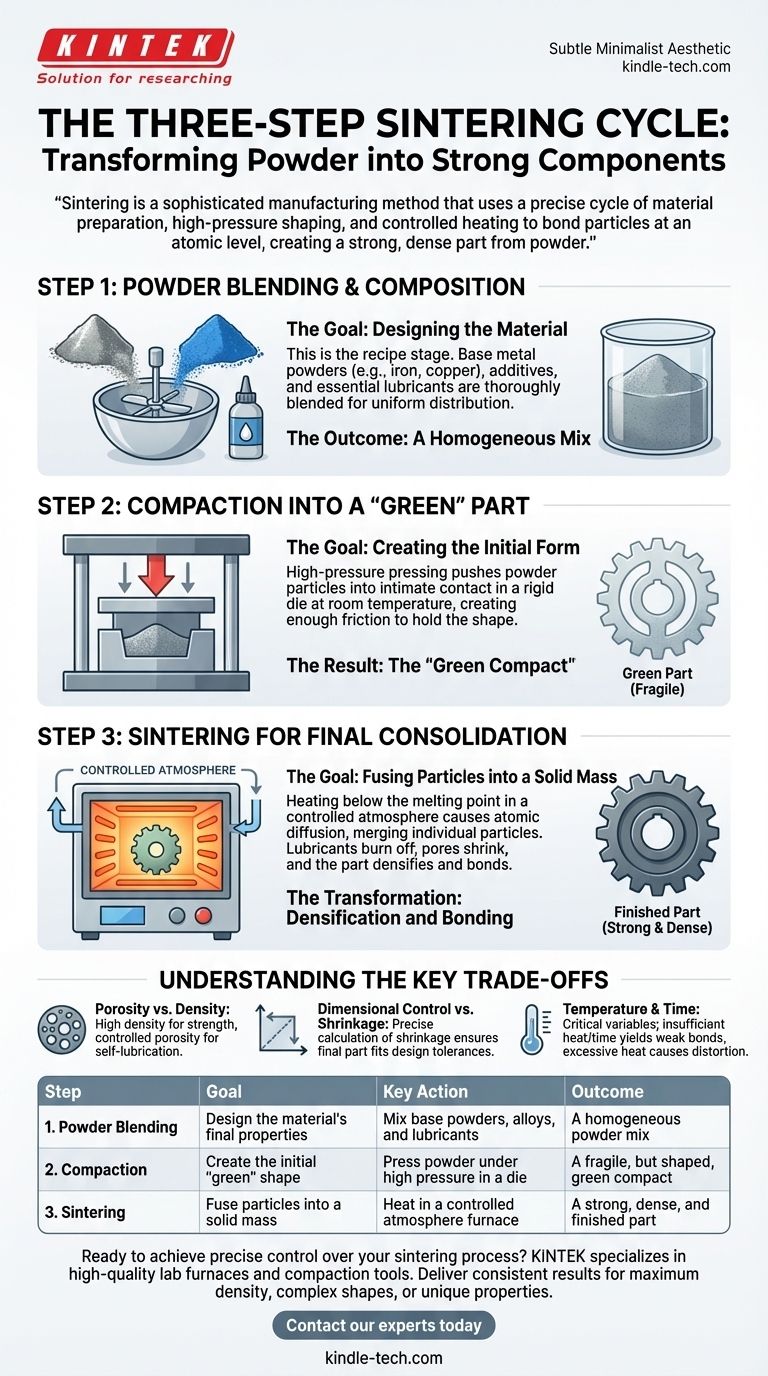

At its core, the sintering process is a three-step cycle designed to transform loose metallic or ceramic powder into a strong, solid component. The universally recognized steps are first blending the raw powders, then compacting them into a preliminary shape, and finally, heating the shape in a furnace to fuse the particles together into a unified mass.

Sintering is not a process of simple melting. It is a sophisticated manufacturing method that uses a precise cycle of material preparation, high-pressure shaping, and controlled heating to bond particles at an atomic level, creating a strong, dense part from powder.

Step 1: Powder Blending and Composition

The first stage of the cycle is foundational, as the composition of the powder mix determines the final properties of the component.

The Goal: Designing the Material

This is the recipe stage. The choice of base metal powders (like iron, copper, or nickel) and additives dictates the final part's strength, hardness, corrosion resistance, and other characteristics.

The Ingredients: Powders and Additives

A typical mix includes the primary metal powder, alloying elements for enhanced properties, and processing aids. A common additive is a lubricant, which is essential for reducing friction and wear on the tooling during the next step (compaction).

The Outcome: A Homogeneous Mix

The powders are thoroughly blended to ensure a uniform distribution of all elements. An inconsistent mix will lead to a finished part with unpredictable performance and potential structural flaws.

Step 2: Compaction into a "Green" Part

With the powder prepared, the next step is to give the material its desired shape through immense pressure.

The Goal: Creating the Initial Form

Compaction mechanically presses the loose powder into a solid object with specific geometric features. This is typically done at room temperature using a rigid die or mold.

The Mechanism: High-Pressure Pressing

The blended powder is loaded into a die cavity and compressed under high pressure. This force pushes the powder particles into intimate contact, creating enough particle-to-particle friction and cold welds to hold the shape together.

The Result: The "Green Compact"

The output of this stage is known as a green compact or green part. This part has the desired shape and dimensions but is mechanically fragile. Its strength is just enough to allow for careful handling and transfer to the sintering furnace.

Step 3: Sintering for Final Consolidation

This final heating stage is what transforms the fragile green compact into a robust, functional component.

The Goal: Fusing Particles into a Solid Mass

The purpose of sintering is to create strong metallurgical bonds between the powder particles, dramatically increasing the part's density, strength, and hardness.

The Mechanism: Controlled Heating Below Melting Point

The green compact is placed in a furnace with a controlled atmosphere to prevent oxidation. It is then heated to a temperature below the melting point of the primary material. At this high temperature, atomic diffusion accelerates, causing the individual particles to merge and bond.

The Transformation: Densification and Bonding

During this stage, any lubricants or binders mixed in Step 1 are burned off. As the particles fuse, pores between them shrink or close, causing the part to densify and undergo a slight, predictable shrinkage. The result is a single, solid piece with the desired mechanical properties.

Understanding the Key Trade-offs

The sintering process is a balance of competing factors. Understanding them is critical to achieving the desired outcome.

Porosity vs. Density

A key characteristic of sintered parts is their residual porosity. While high density is often desired for maximum strength, controlled porosity can be a feature, allowing parts to be self-lubricating when impregnated with oil.

Dimensional Control vs. Shrinkage

The densification that occurs during sintering causes the part to shrink. This shrinkage must be precisely calculated and accounted for in the design of the compaction die to ensure the final part meets its dimensional tolerances.

Temperature and Time

The temperature of the furnace and the time the part spends in it are critical variables. Insufficient heat or time results in weak bonds and low density. Excessive heat can cause unwanted grain growth, melting, or distortion of the part.

Making the Right Choice for Your Goal

The focus of your effort depends entirely on the intended application of the final component.

- If your primary focus is achieving maximum strength and density: Your success is determined by the final sintering stage, requiring precise control over furnace temperature, time, and atmosphere.

- If your primary focus is creating complex shapes with high precision: The design of the compaction die and accurately accounting for material shrinkage are your most critical concerns.

- If your primary focus is developing a material with unique properties (e.g., magnetism or self-lubrication): Your success is defined in the initial powder blending stage, where you control the precise recipe of materials.

Mastering these three distinct stages gives you complete control over the final structure and performance of the sintered part.

Summary Table:

| Step | Goal | Key Action | Outcome |

|---|---|---|---|

| 1. Powder Blending | Design the material's final properties | Mix base powders, alloys, and lubricants | A homogeneous powder mix |

| 2. Compaction | Create the initial "green" shape | Press powder under high pressure in a die | A fragile, but shaped, green compact |

| 3. Sintering | Fuse particles into a solid mass | Heat in a controlled atmosphere furnace | A strong, dense, and finished part |

Ready to achieve precise control over your sintering process?

The three-step cycle is the foundation, but success depends on reliable equipment. KINTEK specializes in high-quality lab furnaces and compaction tools designed for the exacting demands of sintering. Whether your goal is maximum part density, complex shapes, or unique material properties, our solutions deliver the consistent results you need.

Contact our experts today to discuss how KINTEK's equipment can enhance your sintering cycle and help you produce stronger, more precise parts.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations