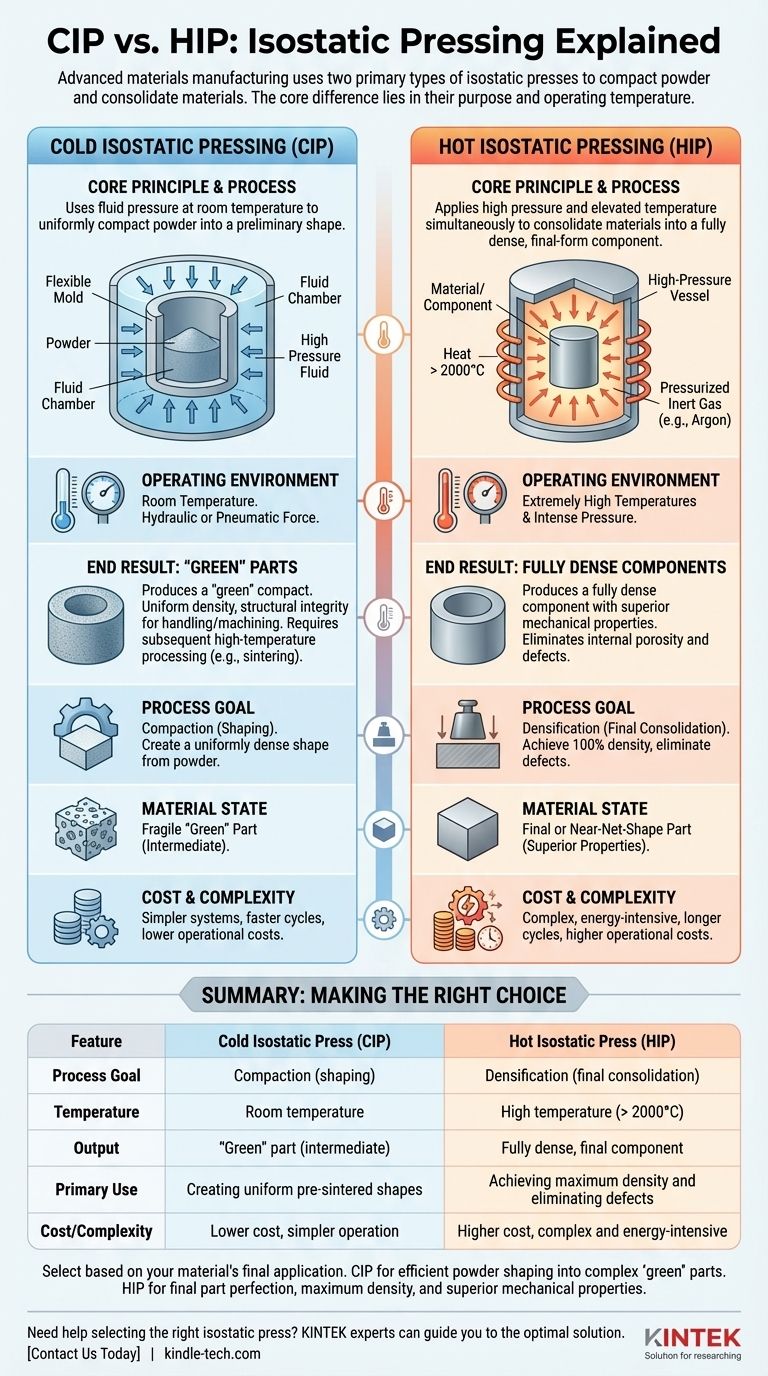

Within the field of advanced materials manufacturing, the two primary types of isostatic presses are the Cold Isostatic Press (CIP) and the Hot Isostatic Press (HIP). A CIP uses fluid pressure at room temperature to uniformly compact powder into a preliminary shape. In contrast, a HIP applies both high pressure and elevated temperature simultaneously to consolidate materials into a fully dense, final-form component.

The fundamental difference is not merely temperature, but purpose. Cold Isostatic Pressing is a shaping step to create a uniform "green" part, while Hot Isostatic Pressing is a final consolidation step to achieve maximum density and eliminate internal defects.

Understanding Cold Isostatic Pressing (CIP)

The Core Principle

In a CIP process, a powder is sealed in a flexible, elastomeric mold. This mold is then submerged in a fluid chamber, and high pressure is applied to the fluid. This pressure is transmitted uniformly from all directions onto the mold, compacting the powder inside.

The Operating Environment

As the name implies, this process occurs at or near room temperature. The force is purely hydraulic or pneumatic; no heat is intentionally added to the system.

The End Result: "Green" Parts

The output of a CIP is a "green" compact. This component has a uniform density and enough structural integrity to be handled and machined. However, it is not fully dense and requires a subsequent high-temperature process, such as sintering or hot isostatic pressing, to achieve its final material properties.

Understanding Hot Isostatic Pressing (HIP)

The Core Principle

A HIP process places the material or component inside a high-pressure containment vessel. The vessel is heated to an elevated temperature while an inert gas, typically argon, is pressurized. This combination of heat and isostatic pressure closes internal porosity.

The Operating Environment

HIP operates at extremely high temperatures, often over 2,000°C (3,632°F), and intense pressures. This environment allows for plastic deformation and diffusion bonding at the atomic level, effectively welding internal voids shut.

The End Result: Fully Dense Components

The result of HIP is a fully dense component, often with mechanical properties that are superior to those achieved through casting or forging. It can be used to consolidate powders into a solid form or to heal defects in pre-existing parts, like castings.

Understanding the Trade-offs: CIP vs. HIP

Process Goal

CIP is a compaction process. Its primary goal is to create a uniformly dense shape from a powder before final consolidation.

HIP is a densification process. Its goal is to achieve 100% density, eliminate internal defects, and create a finished, high-performance part.

Material State

CIP produces a fragile "green" part that represents an intermediate manufacturing step.

HIP produces a final or near-net-shape part with superior mechanical properties, often requiring little to no subsequent work.

Cost and Complexity

CIP systems are generally simpler, have faster cycle times, and are less expensive to operate.

HIP systems are highly complex and energy-intensive due to the extreme heat and pressure, resulting in longer cycles and significantly higher operational costs.

Making the Right Choice for Your Goal

Selecting the correct isostatic process depends entirely on your material's final application and your manufacturing workflow.

- If your primary focus is creating a uniform, pre-sintered part: Use Cold Isostatic Pressing (CIP) to efficiently compact powder into a complex "green" shape for subsequent processing.

- If your primary focus is achieving maximum material density and eliminating defects: Use Hot Isostatic Pressing (HIP) to create a final, high-performance component with superior mechanical properties.

Ultimately, knowing whether you need to shape a powder (CIP) or perfect a final part (HIP) is the key to leveraging these powerful technologies effectively.

Summary Table:

| Feature | Cold Isostatic Press (CIP) | Hot Isostatic Press (HIP) |

|---|---|---|

| Process Goal | Compaction (shaping) | Densification (final consolidation) |

| Temperature | Room temperature | High temperature (> 2000°C) |

| Output | "Green" part (intermediate) | Fully dense, final component |

| Primary Use | Creating uniform pre-sintered shapes | Achieving maximum density and eliminating defects |

| Cost/Complexity | Lower cost, simpler operation | Higher cost, complex and energy-intensive |

Need help selecting the right isostatic press for your lab's advanced materials workflow? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can guide you to the optimal solution—whether you require efficient powder shaping with CIP or final part perfection with HIP. Contact us today to discuss how our solutions can enhance your material properties and manufacturing efficiency!

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What are the disadvantages of powder metallurgy? Key Limitations in Strength and Size

- What is cold isostatic pressing mold material? Essential Elastomers for Uniform Density

- How big is the isostatic pressing market? A Deep Dive into the $1.2B+ Advanced Manufacturing Enabler

- What is the process of isostatic graphite? A Guide to High-Performance, Uniform Material Creation

- Why is cold working better than hot working? A Guide to Choosing the Right Metal Forming Process