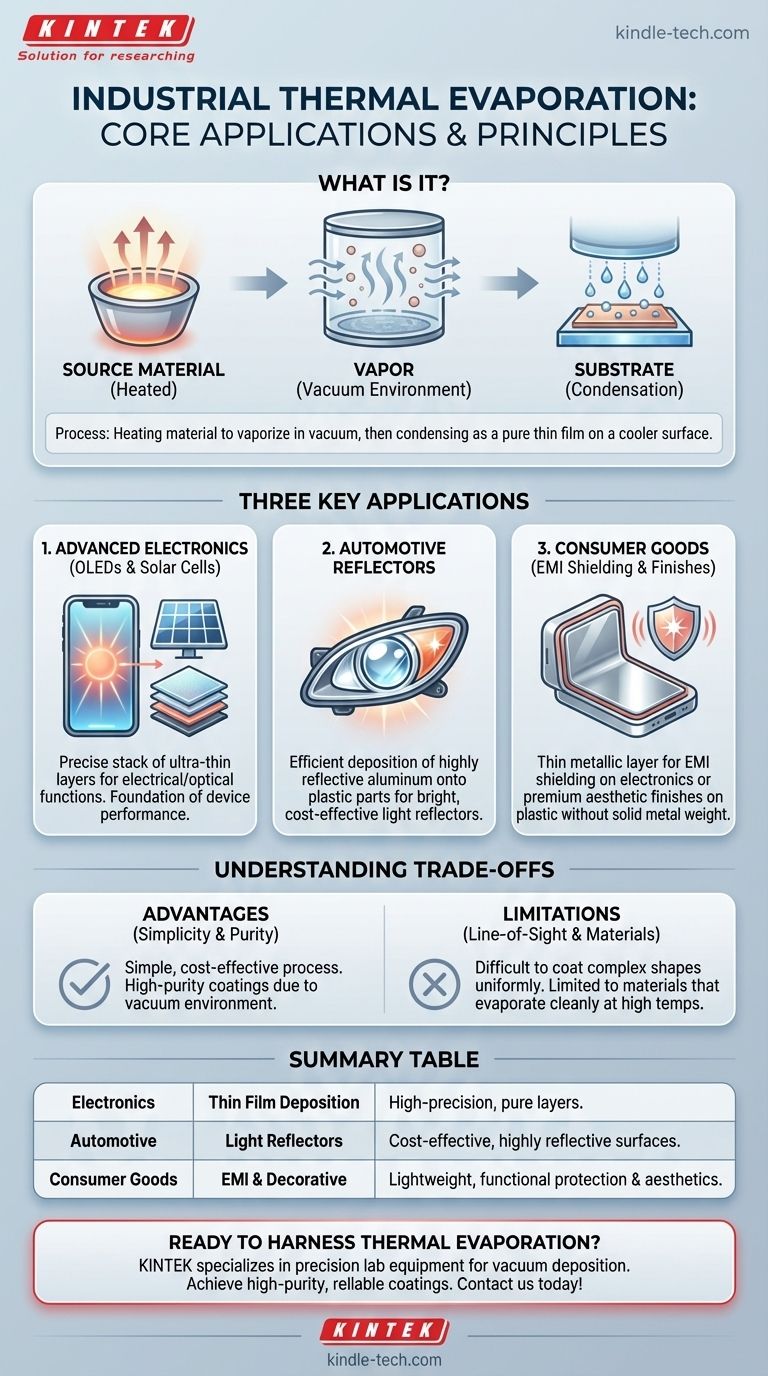

Evaporation is a cornerstone of modern manufacturing, enabling the creation of everything from advanced electronics to protective automotive parts and high-end decorative finishes. Three key industrial applications include depositing thin films for OLED screens and solar cells, creating light reflectors for the automotive industry, and applying metallic coatings to consumer goods for EMI shielding or aesthetic appeal.

At its core, industrial evaporation is not about simple drying. It is a sophisticated vacuum deposition technique used to apply ultra-thin, highly pure films of a material onto a surface, giving that product specific optical, electrical, or aesthetic properties.

What is Industrial Thermal Evaporation?

The term "evaporation" in an industrial context almost always refers to thermal evaporation. This is a specific type of Physical Vapor Deposition (PVD), a process for creating high-performance coatings.

The Core Principle: Heating and Vaporization

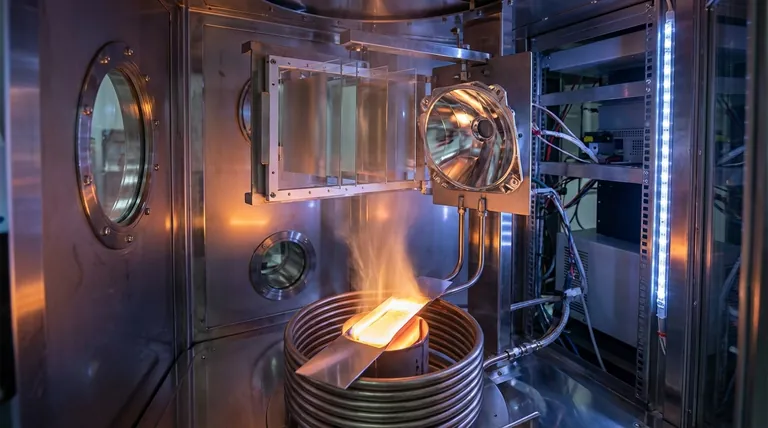

The process begins by placing a source material, such as a metal like aluminum, into a high-vacuum chamber. This material is then heated until it evaporates, turning from a solid into a gas or vapor.

The Deposition Process: Condensation on a Substrate

This vapor then travels through the vacuum and makes contact with a cooler object, known as the substrate. Upon contact, the vapor rapidly condenses back into a solid, forming a very thin, uniform film on the substrate's surface.

Why a Vacuum is Essential

The entire process must occur in a vacuum for two critical reasons. First, the vacuum ensures the vaporized material remains pure and doesn't react with air. Second, it allows the vapor molecules to travel in a straight line directly to the substrate, ensuring a clean and direct coating.

A Closer Look at Key Applications

Thermal evaporation is valued for its versatility, enabling a wide range of products across different sectors.

Application 1: Advanced Electronics (OLEDs & Solar Cells)

In devices like OLED screens and solar cells, performance depends on a precise stack of incredibly thin material layers. Thermal evaporation is used to deposit these layers, each with a specific electrical or optical function, building the foundation of the device's performance.

Application 2: Automotive Light Reflectors

The brilliant, mirror-like surface inside a car's headlight is not polished metal. It is typically a plastic part coated with a thin, highly reflective layer of aluminum applied using thermal evaporation. This process is efficient, cost-effective, and creates a perfect reflective surface.

Application 3: EMI/RFI Shielding & Decorative Finishes

Many plastic electronic casings are coated with a thin layer of metal to provide EMI (electromagnetic interference) shielding, protecting the sensitive components inside. The same process is also used for purely decorative purposes, such as giving a plastic cosmetic cap a premium, metallic finish without the cost or weight of solid metal.

Understanding the Trade-offs

While powerful, thermal evaporation is not the solution for every challenge. It's important to understand its advantages and limitations.

Advantage: Simplicity and Purity

Compared to other deposition methods, thermal evaporation is a relatively simple and cost-effective process. Because it happens in a vacuum, it produces coatings of very high purity.

Limitation: Line-of-Sight Deposition

The vapor travels in a straight line from the source to the substrate. This makes it difficult to uniformly coat complex, three-dimensional shapes with undercuts or hidden surfaces without sophisticated part rotation.

Limitation: Material Constraints

The process is best suited for materials that evaporate cleanly at high temperatures. Materials that decompose or react when heated cannot be effectively deposited using this method.

Making the Right Choice for Your Goal

To apply this knowledge, consider the primary goal of the coating.

- If your primary focus is high-precision electronics: Evaporation is a critical technology for building the layered, functional structures in components like OLEDs and solar cells.

- If your primary focus is functional, high-volume surfaces: The process is ideal and cost-effective for creating reflective or conductive coatings for automotive, aerospace, or medical parts.

- If your primary focus is aesthetic and cost-effective finishes: It provides a premium metallic look for consumer goods without the expense and weight of using solid metal.

Ultimately, thermal evaporation demonstrates how a fundamental physical principle is harnessed to create the sophisticated and reliable products we use every day.

Summary Table:

| Application | Industry | Key Benefit |

|---|---|---|

| Thin Film Deposition | Electronics (OLEDs, Solar Cells) | High-precision, pure layers for device performance |

| Light Reflectors | Automotive | Cost-effective, highly reflective surfaces |

| EMI Shielding & Decorative Coatings | Consumer Goods | Lightweight, aesthetic, and functional protection |

Ready to harness the power of thermal evaporation for your projects? KINTEK specializes in precision lab equipment and consumables for vacuum deposition processes. Whether you're developing advanced electronics, automotive components, or consumer goods, our expertise ensures you achieve high-purity, reliable coatings. Contact us today to discuss how our solutions can elevate your manufacturing process!

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Evaporation Boat for Organic Matter

People Also Ask

- What is the process of thermal evaporation in PVD? A Step-by-Step Guide to Thin Film Deposition

- What is thermal evaporation used to deposit? A Guide to Metals, Compounds, and Key Applications

- What is the widely used boat made of in thermal evaporation? Choosing the Right Material for High-Purity Deposition

- What are the drawbacks of thermal evaporation? Understanding the Limitations for High-Performance Applications

- What is the meaning of thermal evaporation? A Guide to Simple, Cost-Effective Thin Film Coating