To braze stainless steel, you must use a filler metal and a method designed to overcome the material's tough, protective oxide layer. Common filler metals include silver-based, copper-based, and nickel-based alloys. Success depends entirely on removing the surface oxides, which can be accomplished either with a chemical flux or by using a controlled atmosphere in a furnace.

The central challenge of brazing stainless steel isn't the steel itself, but the invisible layer of chromium oxide on its surface. Your choice of filler metal and process must be entirely focused on defeating this barrier to achieve a strong, reliable joint.

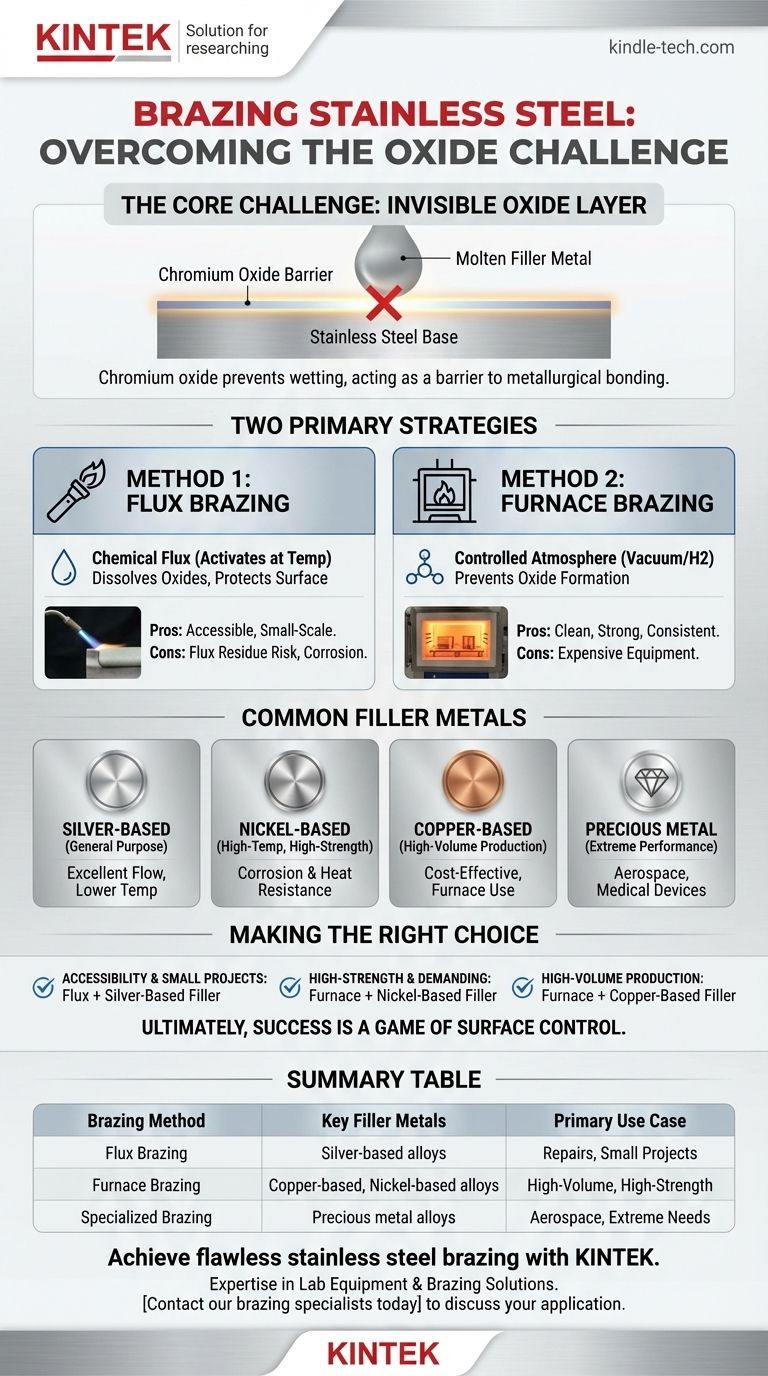

The Core Challenge: Overcoming the Oxide Layer

Brazing works by creating a metallurgical bond between a filler metal and the base metals. For this to happen, the liquid filler must be able to "wet" and spread across the component surfaces. With stainless steel, this fundamental step is uniquely challenging.

What Makes Stainless Steel Difficult?

Stainless steel's corrosion resistance comes from its chromium content. This chromium readily reacts with oxygen to form a very stable, passive, and self-healing layer of chromium oxide on the surface.

While this oxide layer is excellent for preventing rust, it acts as a barrier that prevents liquid braze filler metal from making contact with the underlying steel. Elements like titanium, manganese, and nickel can further complicate this oxide layer.

The Principle of "Wetting"

"Wetting" is the ability of a liquid to maintain contact with a solid surface. Proper wetting is non-negotiable for a successful braze joint.

The oxide film on stainless steel prevents wetting. The molten filler metal will simply bead up on the surface, like water on a waxed car, instead of spreading and flowing into the joint. Therefore, any successful stainless steel brazing strategy must first address the oxide.

Choosing Your Brazing Method and Materials

Your approach to defeating the oxide layer will dictate the process and materials you use. There are two primary strategies: using a chemical flux or controlling the atmosphere.

Common Filler Metals for Stainless Steel

A wide range of filler metals can be used, with the selection depending on the application's temperature, strength, and corrosion requirements.

- Silver-based fillers: Very common for general-purpose and lower-temperature applications. They have excellent flow characteristics.

- Nickel-based fillers: Used for high-temperature and high-strength applications, offering excellent corrosion and heat resistance.

- Copper-based fillers: Often used in furnace brazing under controlled atmospheres. They are cost-effective for high-volume production.

- Precious metal fillers (e.g., gold, palladium): Used in highly specialized applications requiring extreme performance, such as in aerospace or medical devices.

Method 1: Brazing with Flux

For torch or induction brazing in open air, a chemical flux is required. The flux is a chemical mixture that becomes active at brazing temperatures.

Its job is to dissolve the stainless steel oxides and protect the surface from re-oxidizing during heating, allowing the filler metal to wet the clean steel underneath.

Method 2: Furnace Brazing

Furnace brazing eliminates the need for flux by controlling the environment around the parts. By heating the assembly in a specialized furnace, you can prevent oxides from forming in the first place.

This is typically done in a vacuum or a controlled atmosphere of specific gases (e.g., hydrogen). The high temperature and lack of oxygen allow the filler metal to wet the surfaces cleanly.

Understanding the Trade-offs

Choosing between flux and furnace brazing involves significant trade-offs in complexity, cost, and final quality.

Flux Brazing: Pros and Cons

This method is more accessible for smaller-scale work. However, flux itself can introduce problems. If not completely removed after brazing, leftover flux can trap contaminants and cause corrosion in the finished joint.

Furnace Brazing: Pros and Cons

This process produces exceptionally clean, strong, and consistent joints with no flux residue to clean up. It is ideal for complex assemblies and high-volume production. The primary drawback is the requirement for expensive and complex furnace equipment.

Making the Right Choice for Your Application

Your final decision should be guided by your project's specific requirements for strength, cleanliness, and production volume.

- If your primary focus is accessibility for repairs or small projects: A torch, a silver-based filler metal, and a high-quality black flux designed for stainless steel is the most direct approach.

- If your primary focus is high-strength joints for demanding applications: A nickel-based filler metal applied via vacuum furnace brazing provides superior performance and reliability.

- If your primary focus is high-volume, cost-effective production: Furnace brazing with a copper-based filler metal is an established industrial standard for many applications.

Ultimately, successful stainless steel brazing is a game of surface control.

Summary Table:

| Brazing Method | Key Filler Metals | Primary Use Case |

|---|---|---|

| Flux Brazing | Silver-based alloys | Repairs, small projects, general-purpose applications |

| Furnace Brazing | Copper-based, Nickel-based alloys | High-volume production, high-strength, high-temperature applications |

| Specialized Brazing | Precious metal alloys (e.g., gold) | Aerospace, medical devices, extreme performance needs |

Achieve flawless stainless steel brazing with KINTEK.

Whether you are developing a new product or optimizing your production line, selecting the right brazing materials and method is critical for joint strength and integrity. KINTEK specializes in providing the high-quality lab equipment and consumables, including furnace systems and brazing alloys, necessary for precise, repeatable results.

Our experts can help you navigate the complexities of oxide layer management to ensure your brazing process is efficient, cost-effective, and reliable.

Contact our brazing specialists today to discuss your specific application and discover how KINTEK can support your laboratory's success.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What metals can be joined by brazing? Discover the Versatility of Modern Brazing Techniques

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- What are the factors that affect the strength of a brazed joint? Master the 4 Keys to a Perfect Bond

- Which element made stainless steel difficult to brazed? It's Chromium's Oxide Layer

- What is vacuum brazing? The Ultimate Guide to High-Purity, Flux-Free Metal Joining