Compression molding is most frequently used to manufacture large, flat, or moderately curved parts from thermosetting plastics and high-strength composite materials. Its primary applications are in the automotive, aerospace, electrical, and industrial sectors, where material strength, heat resistance, and dimensional stability are more critical than rapid production speed.

The choice to use compression molding is not about chasing a popular trend; it's a deliberate engineering decision. While injection molding dominates the world of thermoplastics, compression molding remains the superior and often only viable process for creating large, high-strength parts from thermoset and composite materials.

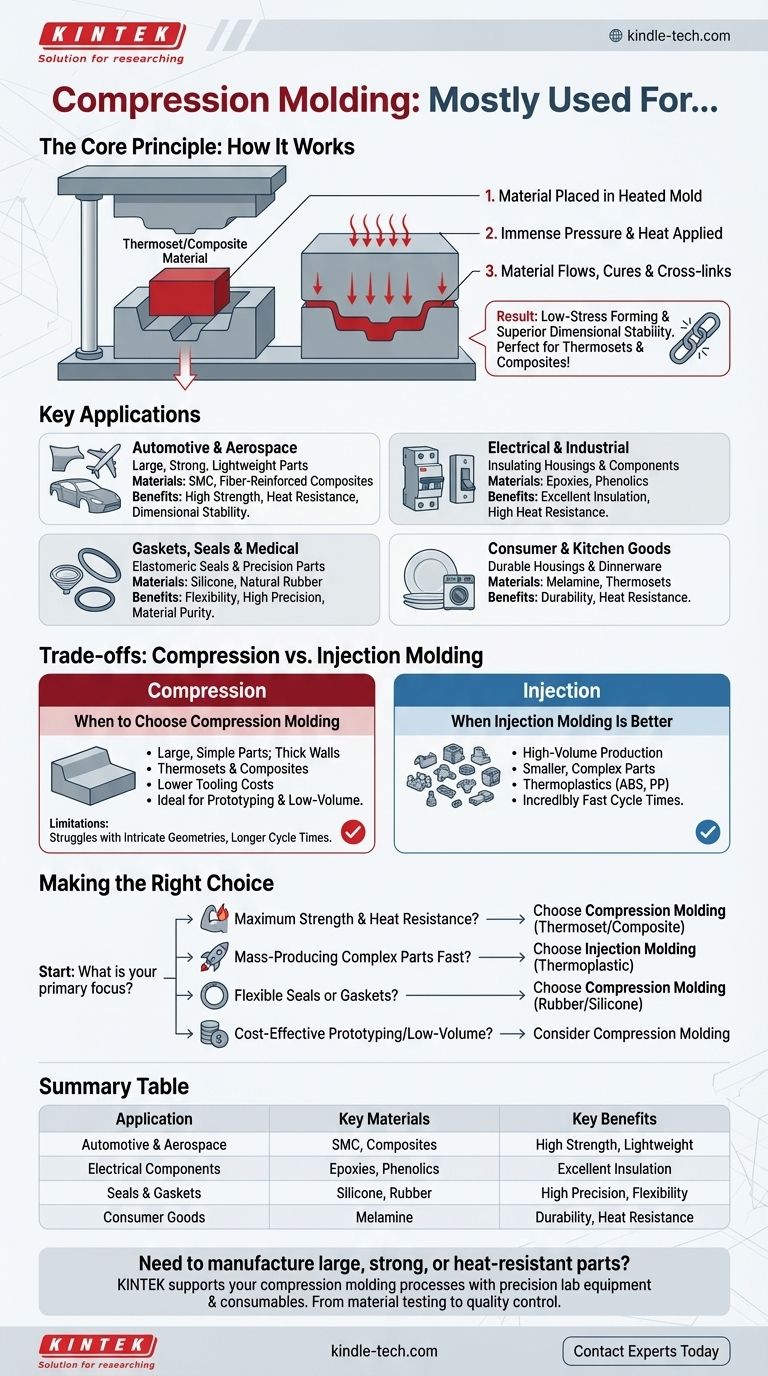

The Core Principle: Why It Excels with Certain Materials

Compression molding is a fundamentally simple process: a measured amount of material is placed in a heated mold, which is then closed under immense pressure, forcing the material to fill the cavity and cure. This simple mechanism is precisely why it works so well for specific materials and applications.

The Thermoset and Composite Connection

Thermosetting plastics, like epoxies and phenolics, and composites, like Sheet Molding Compound (SMC), undergo an irreversible chemical reaction (cross-linking) when heated.

The compression molding process—applying sustained heat and pressure over a period of minutes—is perfectly suited to facilitate this curing process. This ensures the part is fully cross-linked, resulting in exceptional rigidity, heat resistance, and strength.

The Advantage of Low-Stress Forming

Unlike injection molding, where molten plastic is forced at high velocity through narrow channels, compression molding gently flows the material into its final shape within the mold cavity.

This results in significantly less residual stress in the finished part. The benefits are superior dimensional stability and a reduced risk of warping or cracking over the product's lifespan.

Key Applications Where Compression Molding Excels

The unique advantages of the process make it the go-to choice in several key industries.

Automotive and Transportation

This is the largest market for compression molding. It is used to produce large, strong, and lightweight components like vehicle body panels, hoods, spoilers, and structural components from SMC and other fiber-reinforced composites.

Electrical and Industrial Components

Thermoset materials have excellent electrical insulating properties and high heat resistance. This makes compression molding ideal for producing circuit breaker housings, electrical insulators, switchgear, and motor components.

Gaskets, Seals, and Medical Parts

The process is perfectly suited for elastomers like silicone and natural rubber. This makes it the standard method for producing O-rings, seals, diaphragms, and silicone medical device components that require high precision and material purity.

Consumer and Kitchen Goods

A classic example is durable dinnerware made from melamine, a thermosetting plastic. The process is also used for appliance housings, knobs, and handles where durability and heat resistance are required.

Understanding the Trade-offs: Compression vs. Injection Molding

No process is perfect for every job. Understanding the trade-offs between compression and injection molding is critical for making an informed decision.

When to Choose Compression Molding

This process is the clear winner for large, relatively simple parts with thick walls, especially when using thermosets or composite materials. The lower pressure requirements often lead to less expensive tooling, making it a viable option for prototyping and lower-volume production runs.

When Injection Molding Is Better

For high-volume production of smaller, more complex parts from thermoplastic materials (like ABS, polypropylene, or polycarbonate), injection molding is vastly superior. Its incredibly fast cycle times (measured in seconds, not minutes) make it the standard for mass-market products.

Limitations in Part Complexity

Compression molding struggles with highly intricate geometries, sharp internal corners, and features like undercuts that are easily handled by injection molding. The gentle flow of the material is not suited for filling tiny, complex details.

The Impact of Cycle Time

The primary drawback of compression molding is its long cycle time, which is necessary for the material to cure properly. This makes it less economical for producing millions of identical parts compared to the rapid cycles of injection molding.

Making the Right Choice for Your Project

Selecting the correct manufacturing process requires aligning your part's requirements with the core strengths of the technology.

- If your primary focus is maximum strength and heat resistance for a large part: Compression molding with a thermoset or fiber-reinforced composite is your best option.

- If your primary focus is mass-producing complex thermoplastic parts at high speed: Injection molding is the industry standard and the correct choice.

- If your primary focus is creating flexible seals or gaskets from rubber or silicone: Compression molding is the ideal and most common process for these elastomeric materials.

- If your primary focus is cost-effective prototyping or low-volume production: Compression molding's potentially lower tooling costs can make it more accessible than injection molding.

Understanding these core differences empowers you to select the manufacturing process that aligns perfectly with your material, design, and production goals.

Summary Table:

| Application | Key Materials | Key Benefits |

|---|---|---|

| Automotive & Aerospace | Sheet Molding Compound (SMC), Composites | High strength, lightweight, dimensional stability |

| Electrical Components | Epoxies, Phenolics | Excellent insulation, heat resistance |

| Seals & Gaskets | Silicone, Rubber | High precision, material purity, flexibility |

| Consumer Goods | Melamine | Durability, heat resistance |

Need to manufacture large, strong, or heat-resistant parts?

At KINTEK, we specialize in providing the right lab equipment and consumables to support your compression molding processes, from material testing to quality control. Whether you're in automotive, aerospace, or industrial manufacturing, our solutions help you achieve superior part performance and efficiency.

Contact our experts today to discuss how we can support your lab's needs with precision equipment tailored for thermoset and composite applications.

Visual Guide

Related Products

- Double Plate Heating Press Mold for Lab

- Infrared Heating Quantitative Flat Plate Press Mold

- Warm Isostatic Press for Solid State Battery Research

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- What is the hot press molding method? A Guide to Shaping Materials with Heat & Pressure

- How is conventional heating different from induction heating? Direct vs. Indirect Heat Explained

- What are the different types of press machines? Choose the Right Heating Tech for Your Application

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing