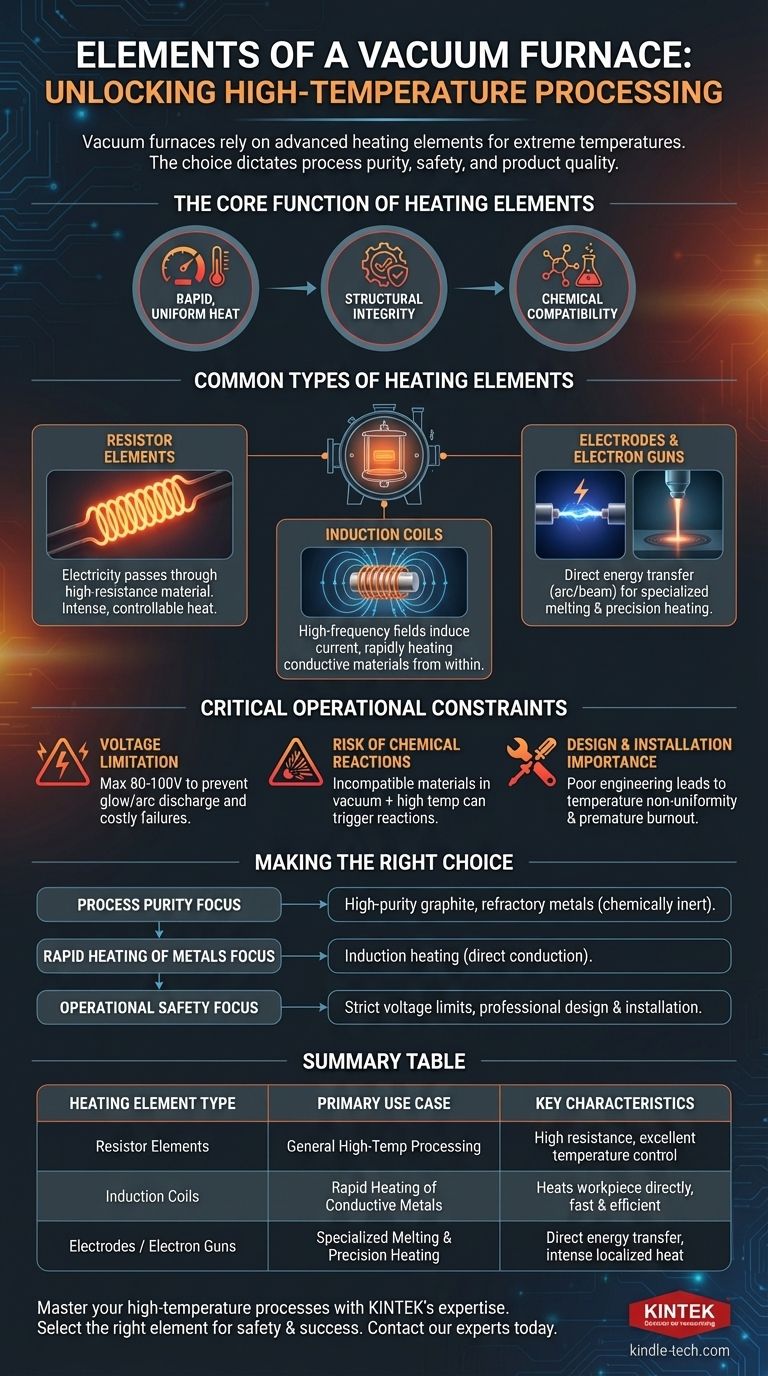

At its core, a vacuum furnace relies on several types of heating elements to generate the extreme temperatures required for processing high-performance materials. The most common types are electrical resistors, induction coils, electrodes, and electron guns, with the specific choice depending entirely on the furnace's intended application and the materials being processed.

The selection of a heating element is not merely a matter of generating heat. It is a critical engineering decision that dictates temperature uniformity, process purity, and operational safety within the furnace's hot zone.

The Core Function of Heating Elements

The role of a heating element extends far beyond simple temperature generation. Its design and material properties directly influence the quality of the final product and the reliability of the entire system.

Achieving Rapid, Uniform Heat

A primary requirement is the ability to heat the workload quickly and evenly. This demands materials with excellent thermal conductivity and design principles that minimize heat loss.

Maintaining Structural Integrity

Heating elements must perform reliably under extreme conditions. They are engineered to resist deformation at high temperatures and provide stable, consistent performance over many operational cycles.

Ensuring Chemical Compatibility

Perhaps the most critical factor is the element's chemical inertness. The material used must not react with the workpiece, as this could contaminate the product and compromise its structural or chemical properties.

Common Types of Heating Elements Explained

While a furnace may use various technologies, the heating sources generally fall into a few key categories.

Resistor Elements

This is the most conventional approach, where electricity is passed through a material with high resistance, such as graphite or molybdenum. This resistance generates intense, controllable heat.

Induction Coils

Induction heating uses powerful, high-frequency electromagnetic fields. A coil generates this field, which induces an electrical current directly within the conductive workpiece, causing it to heat up rapidly from the inside out.

Electrodes and Electron Guns

For more specialized applications, direct energy methods are used. Electrodes can create an electric arc for melting, while electron guns emit a focused beam of high-energy electrons to heat a precise target area.

Critical Operational Constraints

Operating a vacuum furnace involves managing significant risks. The heating system, in particular, has specific constraints that are essential for safe and effective operation.

The Voltage Limitation

The working voltage for electric heating elements is typically kept low, generally not exceeding 80-100 volts. Higher voltages can ionize the low-pressure gas inside the furnace, causing a glow discharge or arc discharge.

This uncontrolled electrical event can severely damage the heating elements and insulation, leading to costly failures and significant safety hazards.

The Risk of Chemical Reactions

Using an inappropriate heating element material can lead to dangerous outcomes. The combination of high temperatures and a vacuum environment can trigger unwanted chemical reactions or even explosions if incompatible materials are present.

The Importance of Design and Installation

The physical design and installation of the heating elements are paramount. Poorly engineered or improperly installed components are a primary source of failure, leading to temperature non-uniformity and premature burnout.

Making the Right Choice for Your Process

Selecting the appropriate heating element technology is fundamental to achieving your desired process outcomes safely and efficiently.

- If your primary focus is process purity: Prioritize element materials like high-purity graphite or refractory metals that are chemically inert to your workpiece.

- If your primary focus is rapid heating of metals: Induction heating is often the most effective method, as it heats the conductive material directly.

- If your primary focus is operational safety and reliability: Ensure the system operates within strict voltage limits and that all components are professionally designed and installed to prevent electrical discharge.

Ultimately, understanding your heating elements is the first step toward mastering your high-temperature vacuum process.

Summary Table:

| Heating Element Type | Primary Use Case | Key Characteristics |

|---|---|---|

| Resistor Elements | General High-Temp Processing | High resistance materials (e.g., graphite, molybdenum); excellent temperature control. |

| Induction Coils | Rapid Heating of Conductive Metals | Heats workpiece directly via electromagnetic fields; fast and efficient. |

| Electrodes / Electron Guns | Specialized Melting & Precision Heating | Direct energy transfer (arc or electron beam) for intense, localized heat. |

Master your high-temperature processes with KINTEK's expertise. Selecting the right heating element is critical for the success and safety of your vacuum furnace operations. Whether your priority is ultimate process purity, rapid heating rates, or operational reliability, KINTEK specializes in providing the precise lab equipment and consumables your laboratory needs. Our team can help you navigate the complexities of element selection, voltage constraints, and installation to ensure optimal performance. Contact our experts today to discuss your specific application and find the perfect solution for your lab.

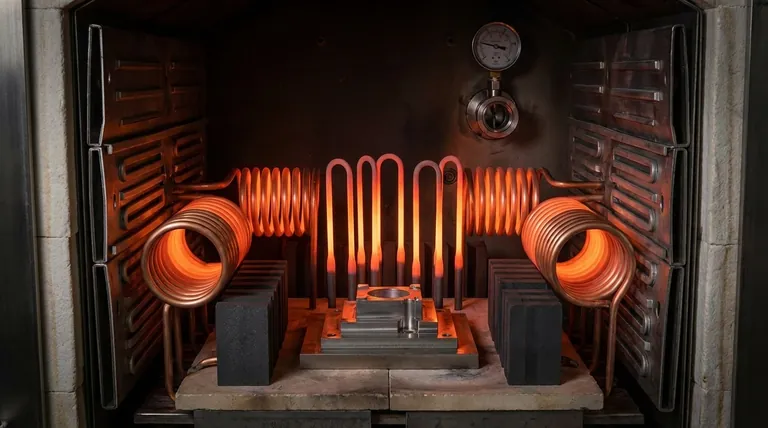

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- What is a retort in heat treatment? Achieve Superior Surface Quality and Metallurgical Control

- What is the process of sintering? A Guide to Powder-Based Manufacturing

- What is the use of furnace in laboratory? Unlock Material Transformation for Your Research

- What is the process of heat treatment furnace? Master the 3 Stages for Precise Material Properties

- Can you vacuum braze aluminum? A Guide to Flux-Free, High-Strength Joining

- Can you heat treat something twice? Yes, and Here's When and How to Do It Correctly

- How does heat treatment process work? Tailor Material Properties for Your Application

- How does a vacuum furnace environment influence sintered Ruthenium powder? Achieve High Purity and Theoretical Density