In short, annealing is a heat treatment process that fundamentally alters a metal's internal structure to make it softer, more ductile, and easier to work with. By heating the metal to a specific temperature and then slowly cooling it, you relieve internal stresses, effectively making the material less brittle and more formable.

Annealing should not be seen as simply "softening" a metal. It is a precise metallurgical process that heals and resets the material's microscopic crystal structure, reversing the hardening effects of mechanical work and preparing it for subsequent shaping or machining.

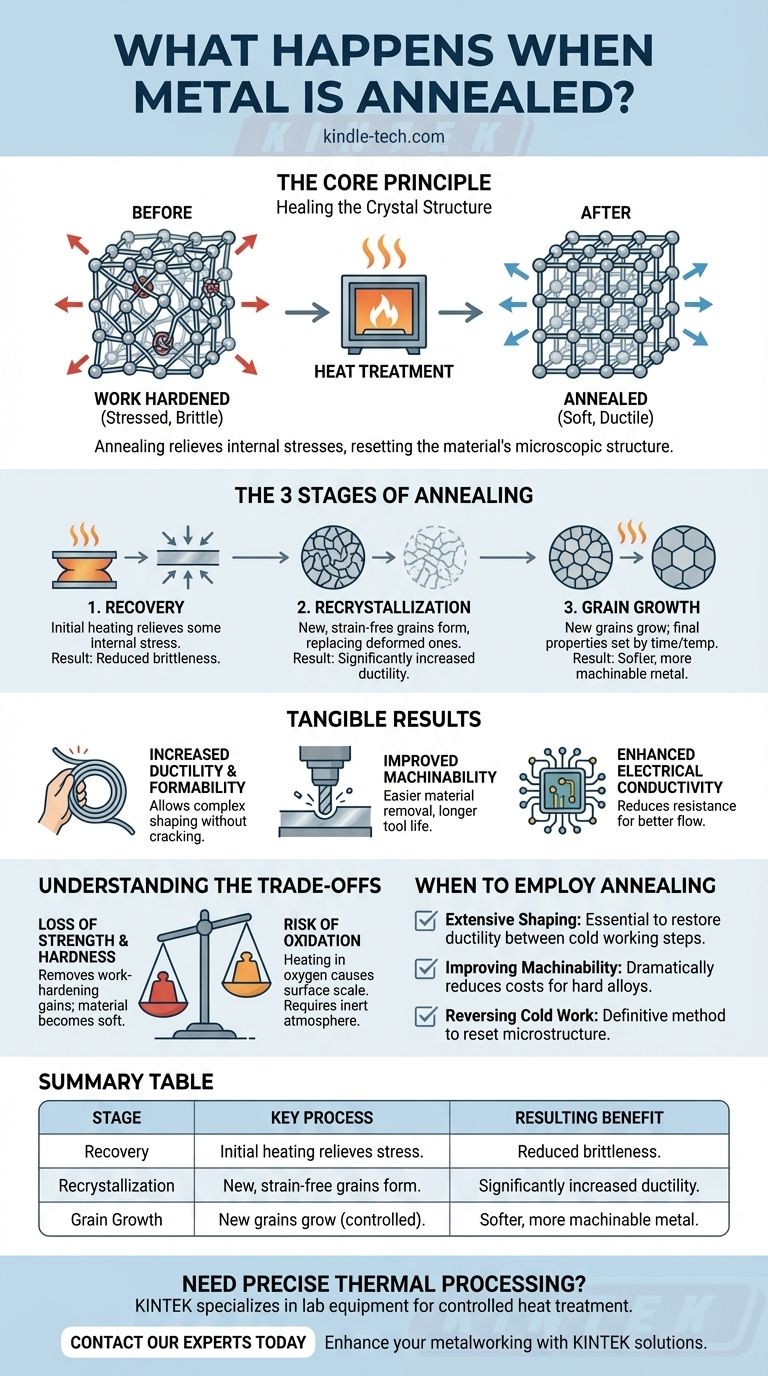

The Core Principle: Healing the Crystal Structure

To understand annealing, you must first understand the problem it solves: work hardening.

What is "Work Hardening"?

When you bend, hammer, roll, or draw a piece of cold metal, it becomes progressively harder and stronger. This effect is known as work hardening or strain hardening.

While this increased hardness can be desirable, it comes at a cost: the metal also becomes less ductile and more brittle, increasing the risk of cracking under further stress.

Internal Stress and Dislocations

At a microscopic level, metals are made of an orderly, crystalline lattice of atoms. Work hardening introduces defects and tangles into this lattice, known as dislocations.

Think of these dislocations as microscopic knots and snags in the material's internal structure. The more tangled these dislocations become, the harder it is for the atomic layers to slide past one another, which is what makes the metal feel hard and brittle.

How Annealing Relieves Stress

Annealing acts as a "reset button" for this internal structure. The process involves three main stages:

- Recovery: The metal is heated, providing thermal energy that allows some internal stresses to be relieved.

- Recrystallization: As the temperature rises further to a specific point, new, strain-free crystal grains begin to form, replacing the deformed grains filled with dislocations. This is the core of the process where the "healing" occurs.

- Grain Growth: If the metal is held at the annealing temperature, these new grains will grow. The final grain size, controlled by temperature and time, significantly influences the material's final properties.

The slow, controlled cooling that follows locks in this new, stress-free structure.

The Tangible Results of Annealing

By resetting the crystal structure, annealing produces several highly practical benefits for manufacturing and engineering.

Increased Ductility and Formability

This is the primary goal of most annealing operations. A metal with a healed crystal structure and fewer dislocations is far more ductile.

It can be bent, stretched, or drawn into complex shapes (like a wire or a deep pan) without cracking, which would be impossible in its work-hardened state.

Reduced Hardness and Improved Machinability

The direct consequence of relieving internal stress is a reduction in hardness. This softer state makes the metal much easier to machine.

Cutting tools can remove material more efficiently, leading to reduced tool wear, faster machining times, and a better surface finish on the final part.

Enhanced Electrical Conductivity

The tangled dislocations in a work-hardened metal impede the flow of electrons. By creating a more orderly and uniform crystal lattice, annealing reduces the material's electrical resistance.

This is particularly critical for materials like copper used in electrical wiring, where maximizing conductivity is essential.

Understanding the Trade-offs

While powerful, annealing is a deliberate choice with specific consequences that must be considered.

The Loss of Strength and Hardness

The primary trade-off is clear: annealing removes the strength and hardness gained from work hardening. The resulting material is soft and may not be suitable for a final application that requires high strength or wear resistance.

For this reason, annealing is often an intermediate step in manufacturing, used to allow for shaping. The part may be hardened again later through a different heat treatment or by subsequent cold work.

The Risk of Oxidation

Heating metal to high temperatures in the presence of oxygen will cause it to oxidize, forming a layer of scale on the surface. This can ruin the surface finish and affect the dimensions of a part.

To prevent this, annealing is often performed in a controlled, inert atmosphere, such as a nitrogen gas mixture, which adds complexity and cost to the process.

When to Employ Annealing

Applying this knowledge depends entirely on your manufacturing or design goal.

- If your primary focus is extensive shaping or forming: Annealing is essential to restore ductility between cold working steps, preventing fractures and material failure.

- If your primary focus is improving machinability: Annealing a work-hardened or naturally hard alloy can dramatically reduce machining costs and improve the quality of the finished part.

- If your primary focus is reversing the effects of cold work: Annealing is the definitive method for resetting a component's microstructure, restoring its original softness and ductility for further processing or use.

Ultimately, annealing is a strategic tool used to precisely control a metal's properties for a specific purpose.

Summary Table:

| Annealing Stage | Key Process | Resulting Benefit |

|---|---|---|

| Recovery | Initial heating relieves some internal stress. | Reduced brittleness. |

| Recrystallization | New, strain-free grains form. | Significantly increased ductility and formability. |

| Grain Growth | New grains grow (controlled by time/temperature). | Final properties are set; softer, more machinable metal. |

Need precise thermal processing for your materials?

Annealing is a critical step in achieving the perfect material properties for your project. KINTEK specializes in the lab equipment and consumables needed for controlled heat treatment processes, serving laboratories and manufacturers who require reliability and precision.

Contact our experts today to discuss how our solutions can enhance your metalworking, improve machinability, and ensure consistent, high-quality results.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What are the advantages of brazing compared to welding? Achieve Clean, Low-Distortion Metal Joining

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- Why would you braze instead of weld? Preserve Material Integrity and Join Dissimilar Metals

- What metals can be joined by brazing? Discover the Versatility of Modern Brazing Techniques

- Why would you braze instead of solder? For Superior Joint Strength and High-Temperature Performance