In the pharmaceutical industry, a filter press is a specialized piece of equipment used to separate solids from liquids with a high degree of control. It is most commonly applied in research and development (R&D) labs, quality control (QC) departments, and for small-scale production, where precision and product purity are paramount.

A filter press is not just a simple sieve; it is a controlled system for precise solid-liquid separation. In pharmaceuticals, its value lies in its suitability for small, high-value batches, ensuring product purity and process repeatability during development and quality assurance.

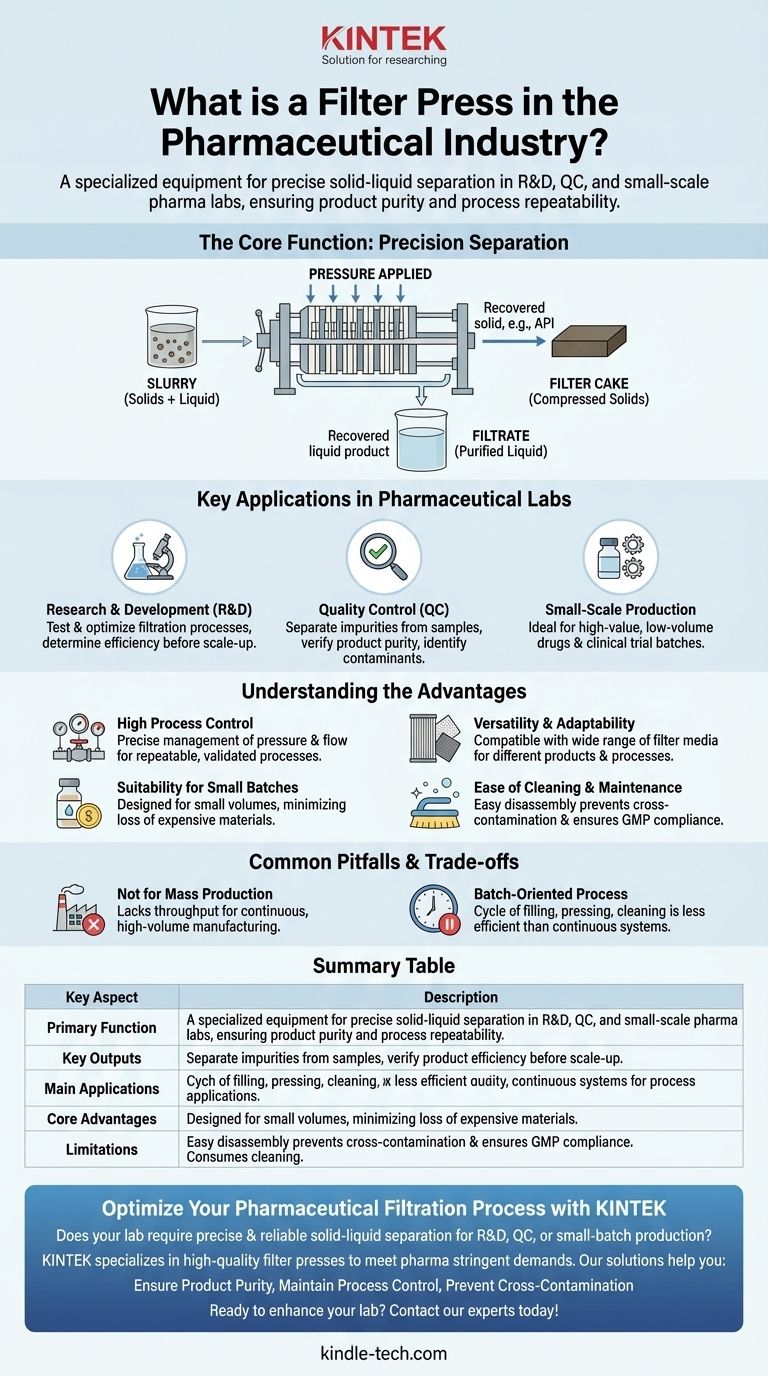

The Core Function: Precision Separation

A filter press performs one of the most fundamental tasks in chemical and pharmaceutical processing: separating solid particles from a liquid slurry. Its design, however, is optimized for control and efficiency on a smaller scale.

How It Works in Principle

A slurry (a mixture of solids and liquid) is pumped into the filter press, which contains a series of filter plates and cloths. As pressure is applied, the liquid is forced through the filter media, emerging as a clear liquid called filtrate. The solid particles are trapped between the plates, forming a compressed solid block known as a filter cake.

The Goal: Purity and Recovery

The objective of this process can be to recover the solids, the liquid, or both. In pharmaceuticals, the solid "cake" might be the valuable Active Pharmaceutical Ingredient (API), while in other cases, the purified liquid filtrate is the desired product.

Key Applications in Pharmaceutical Labs

The laboratory filter press is not a tool for mass production. Instead, its utility is found in environments where control, data, and small volumes are the priority.

Research & Development (R&D)

Scientists use lab-scale filter presses to test and optimize filtration processes for new drugs. They can experiment with different pressures and filter media to determine the most efficient way to purify a compound before scaling up the process.

Quality Control (QC)

In a QC lab, a filter press can be used to separate impurities from a sample batch of a drug product. This allows analysts to verify that the product meets strict purity standards and to identify any unexpected contaminants.

Small-Scale Production

For certain high-value, low-volume drugs, or for producing batches for clinical trials, a laboratory filter press is perfectly suitable. Its smaller size and lower cost make it a practical choice for these limited production runs.

Understanding the Advantages

The filter press is a staple in pharma labs because its characteristics align perfectly with the industry's stringent demands for precision and safety.

High Degree of Process Control

Operators can precisely manage variables like pressure and flow rate. This level of control is essential for creating a repeatable and validated process, which is a core requirement in the pharmaceutical world.

Versatility and Adaptability

Lab filter presses are compatible with a wide variety of filter media. This allows a single unit to be used for many different products and processes, simply by changing the type of filter cloth or paper.

Suitability for Small, High-Value Batches

Early-stage drug development often involves working with small quantities of extremely expensive materials. The filter press is designed for these small volumes, minimizing product loss and making it a cost-effective tool for R&D.

Ease of Cleaning and Maintenance

Preventing cross-contamination between different drug batches is non-negotiable. Filter presses are designed for easy disassembly, cleaning, and reassembly, which is critical for maintaining a sterile environment and complying with Good Manufacturing Practices (GMP).

Common Pitfalls and Trade-offs

While highly valuable, the laboratory filter press is a specialized tool with clear limitations. Understanding these is key to using it correctly.

Not Designed for Mass Production

The primary trade-off is scale. These units are fundamentally designed for small, intermittent batches. They lack the throughput capacity required for the continuous, high-volume manufacturing of a blockbuster drug.

A Batch-Oriented Process

Filtration using a press is a batch process. The cycle involves filling, pressing, cake removal, and cleaning before the next batch can begin. This is less efficient than continuous filtration systems used in large-scale industrial plants.

Making the Right Choice for Your Goal

To determine if a laboratory filter press is the right solution, you must first clarify your primary objective.

- If your primary focus is developing or optimizing a filtration process in R&D: The high control and versatility of a lab filter press make it the ideal tool.

- If your primary focus is verifying batch purity for quality control: Its ability to handle small samples and its ease of cleaning are perfectly suited for accurate, contamination-free QC testing.

- If your primary focus is high-volume commercial drug manufacturing: You must look to larger, industrial-scale filtration systems, as a laboratory press is not designed for this throughput.

Understanding its role as a precision tool for small-scale applications is the key to leveraging it effectively in the pharmaceutical workflow.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Function | Precision separation of solids from liquids in a slurry. |

| Key Outputs | Purified liquid filtrate and a compressed solid filter cake. |

| Main Applications | R&D process development, Quality Control (QC) testing, small-scale production. |

| Core Advantages | High process control, versatility, suitability for small batches, easy cleaning for GMP compliance. |

| Limitations | Designed for batch processing, not for high-volume, continuous manufacturing. |

Optimize Your Pharmaceutical Filtration Process with KINTEK

Does your laboratory require precise and reliable solid-liquid separation for R&D, quality control, or small-batch production? KINTEK specializes in high-quality lab equipment, including filter presses designed to meet the stringent demands of the pharmaceutical industry.

Our solutions help you:

- Ensure Product Purity: Achieve the high levels of purity required for APIs and final products.

- Maintain Process Control: Gain precise control over filtration variables for repeatable, validated results.

- Prevent Cross-Contamination: Benefit from equipment designed for easy cleaning and GMP compliance.

Ready to enhance your lab's capabilities? Contact our experts today to find the perfect filtration solution for your specific pharmaceutical applications!

Visual Guide

Related Products

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

People Also Ask

- What is the number one cause of failure in hydraulic systems? The Silent Killer of Your Equipment

- What are the factors that affect the filtration of the solution? Master the Key Variables for Optimal Performance

- What is a major cause of hydraulic system and component failures? Prevent Costly Downtime with Clean Fluid

- What are the failures in a hydraulic system? Prevent Costly Downtime with Expert Diagnosis

- What are the disadvantages of hydraulic machines? Key Trade-offs in Power and Performance