At its core, a hydraulic forging press is a machine that uses a liquid-based hydraulic system to generate immense, controlled force. This force is used to shape, form, bend, and compress metal and other materials into desired shapes. Its applications span heavy industrial manufacturing in the automotive and aerospace sectors to precise sample preparation in scientific laboratories.

The defining characteristic of a hydraulic press is not just its power, but its ability to apply sustained and precisely controlled pressure throughout its entire stroke. This makes it uniquely suited for complex forming operations that other types of presses cannot accomplish.

The Core Principle: How It Achieves Immense Force

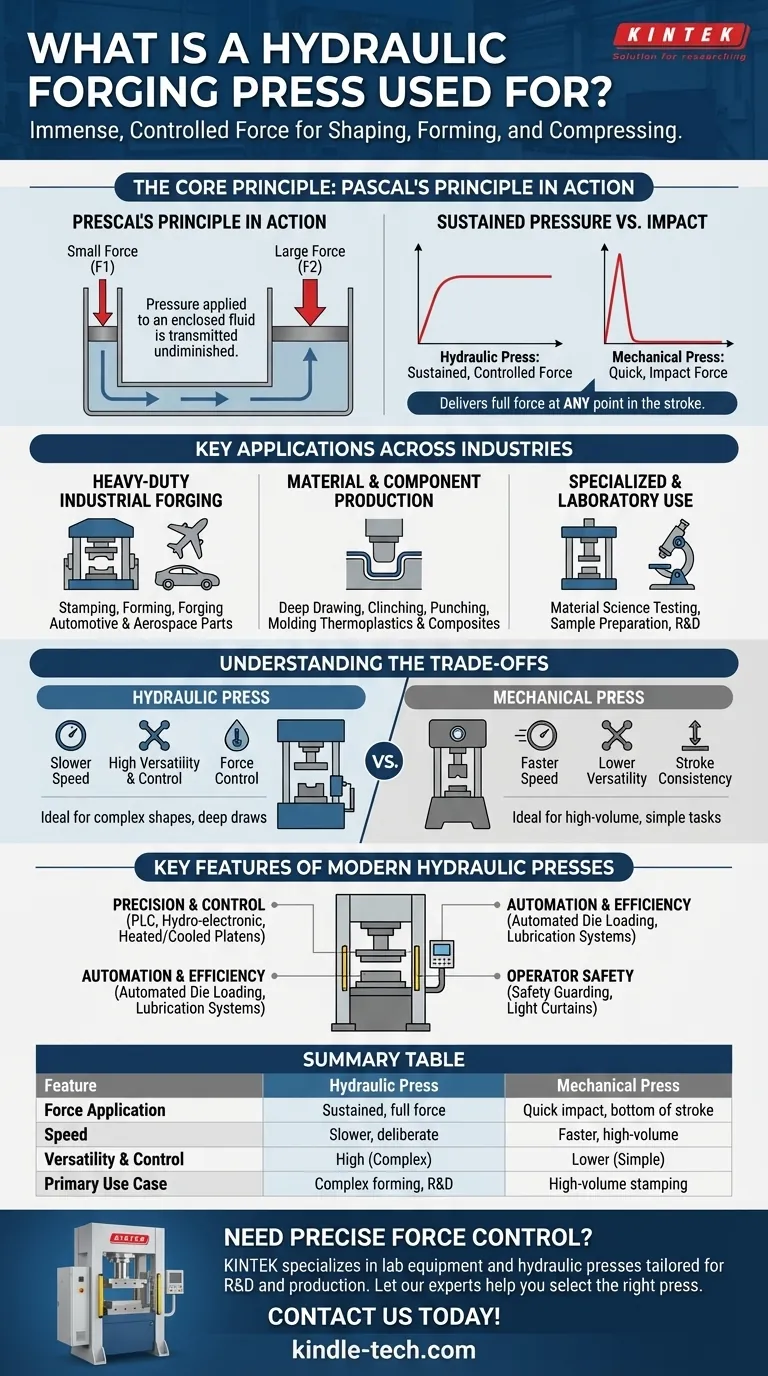

Pascal's Principle in Action

A hydraulic press operates on a fundamental law of physics known as Pascal's principle. This principle states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In simple terms, applying a small force to a small piston in a hydraulic system generates a proportionally massive force on a larger piston. This force multiplication is what allows a relatively small motor to produce thousands of tons of pressure.

Sustained Pressure vs. Impact

Unlike a mechanical press that delivers a quick, sharp blow at a fixed point in its stroke, a hydraulic press can apply its full force at any point in the ram's travel. This ability to deliver slow, sustained pressure is critical for many forming processes.

Key Applications Across Industries

The versatility of the hydraulic press makes it a cornerstone technology in numerous fields. Its use is determined by the need for high force, control, and adaptability.

Heavy-Duty Industrial Forging

In the automotive, aerospace, and defense industries, hydraulic presses are essential for heavy-duty jobs. They are used for stamping body panels, forming structural components, and forging high-strength parts like engine components and landing gear.

Material and Component Production

Hydraulic presses are central to metalworking operations like deep drawing, where a sheet of metal is drawn into a complex, deep shape without tearing. They are also used for clinching, punching, and blanking operations.

Beyond metals, these presses are used to manufacture parts from thermoplastics, carbon fiber composites, and other advanced materials that require both heat and sustained pressure for molding.

Specialized and Laboratory Use

The technology scales down effectively. Small, portable hydraulic mini presses are used in pharmaceutical labs for their low cost and high force-to-size ratio.

Larger laboratory presses are crucial for material science. They test the strength and durability of new materials, investigate the effects of high pressure on substances, and prepare samples for spectroscopic analysis.

Understanding the Trade-offs

No single technology is perfect for every task. Understanding the trade-offs between hydraulic and mechanical presses is key to making an informed decision.

Speed vs. Versatility

The primary trade-off is speed. Mechanical presses are significantly faster, making them ideal for high-volume, repetitive tasks like simple stamping or punching.

Hydraulic presses are slower but offer unparalleled versatility and control. The ability to vary the ram speed, pressure, and stroke length makes them superior for complex shapes, deep draws, and working with sensitive materials.

Force Control vs. Stroke Consistency

A hydraulic press provides absolute control over pressure, but its stroke depth can vary slightly under load. A mechanical press has a highly repeatable, fixed stroke length but only delivers its maximum force at the very bottom of the stroke.

Key Features of Modern Hydraulic Presses

Modern hydraulic presses are sophisticated systems designed for precision, efficiency, and safety in demanding environments.

Precision and Control

Advanced PLC (Programmable Logic Controller) and hydro-electronic controls allow for exact management of pressure, speed, and positioning. Features like heated and cooled platens provide precise temperature control, which is vital for molding composites and certain metal alloys.

Automation and Efficiency

To maximize uptime, modern presses often include automated systems for die loading and unloading and scrap removal. Centralized lubrication systems and water-cooled heat exchangers ensure the machine runs reliably under continuous operation.

Operator Safety

Safety is paramount. Features such as physical safety guarding, light curtains that stop the machine if an operator enters the work area, and area scanners are standard on industrial presses.

Making the Right Choice for Your Application

Selecting the right press depends entirely on your project's specific goals for material, part complexity, and production volume.

- If your primary focus is shaping large, complex, or high-strength parts: A hydraulic press is the superior choice due to its sustained, controllable force.

- If your primary focus is high-volume production of simple, shallow parts: A mechanical press is likely more cost-effective due to its higher operational speed.

- If your primary focus is material testing or small-batch sample creation: A specialized laboratory or mini hydraulic press offers the necessary force and control in a compact form factor.

Ultimately, a hydraulic press is chosen when the manufacturing process demands deliberate power and precise control over raw force.

Summary Table:

| Feature | Hydraulic Press | Mechanical Press |

|---|---|---|

| Force Application | Sustained, full force at any point in the stroke | Quick impact, maximum force only at bottom of stroke |

| Speed | Slower, more deliberate | Faster, ideal for high-volume production |

| Versatility & Control | High; ideal for complex shapes, deep draws, sensitive materials | Lower; best for simple, repetitive tasks |

| Primary Use Case | Complex forming, aerospace/auto parts, material testing, R&D | High-volume stamping, punching, blanking |

Need precise force control for your metal forming or material testing? KINTEK specializes in lab equipment and consumables, including hydraulic presses tailored for R&D and production. Our experts can help you select the right press to enhance your lab's efficiency and achieve superior results. Contact us today to discuss your specific application!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy