At its core, a hydraulic press is a machine that uses fluid pressure to generate immense compressive force. It is a foundational tool used across a vast spectrum of applications, from heavy industrial manufacturing like forging automotive parts and shaping aerospace components to precise scientific work like preparing laboratory samples for analysis.

A hydraulic press is not defined by a single function but by its fundamental ability to multiply force. This principle allows it to perform an incredibly diverse range of tasks, from crushing, bending, and forming the toughest metals to delicately compressing powders into uniform samples for scientific testing.

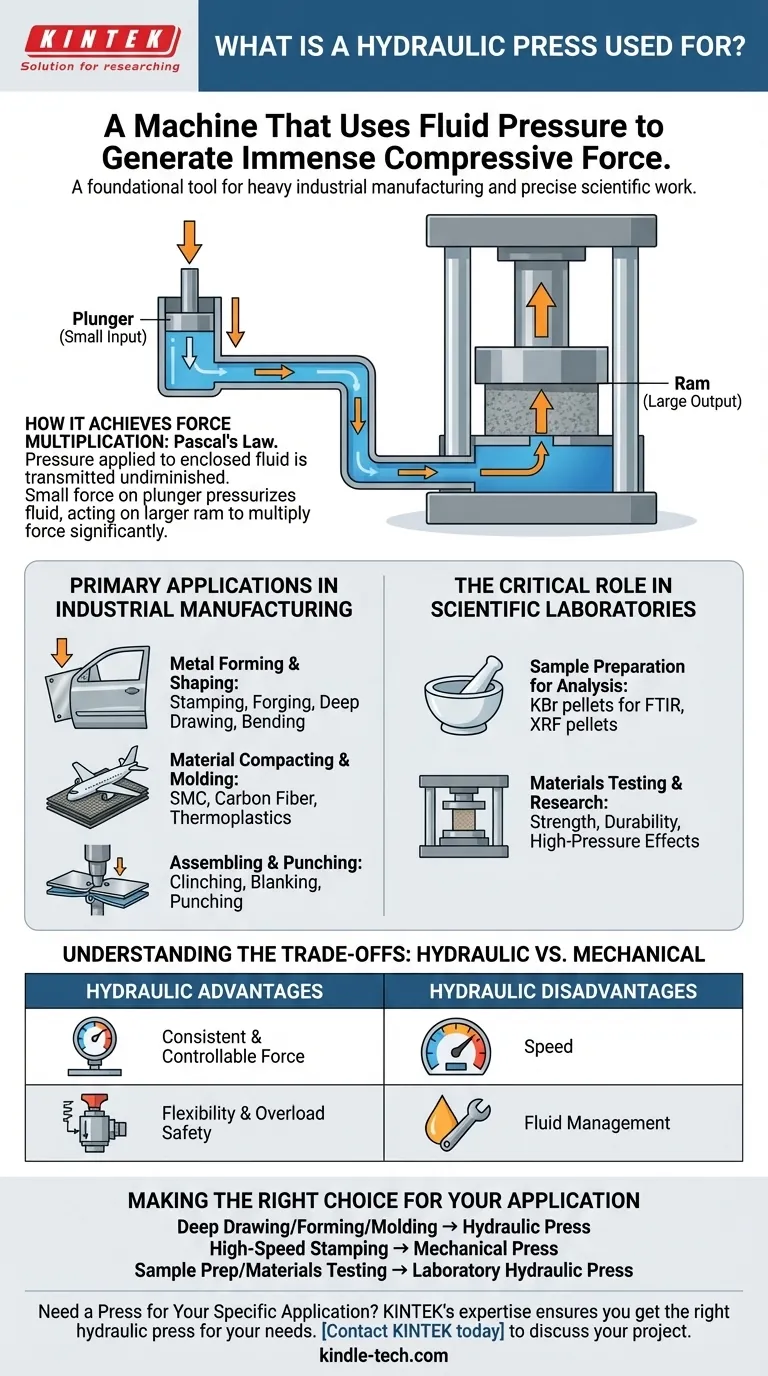

How a Hydraulic Press Achieves Force Multiplication

The versatility of the hydraulic press comes from a simple yet powerful physics principle that allows it to generate tons of force from a relatively small initial input.

The Core Principle: Pascal's Law

A hydraulic press operates on Pascal's Law, which states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In a press, a small force is applied to a small piston (the plunger), which pressurizes hydraulic fluid. This pressure acts on a much larger piston (the ram), multiplying the initial force significantly. This force multiplication is what enables the machine to perform heavy-duty work.

The Key Components

A typical hydraulic press consists of a simple frame that holds the core components. These include the hydraulic cylinder (containing the pistons and fluid), a pump to generate initial pressure, and a frame or bed that supports the material being worked on.

Primary Applications in Industrial Manufacturing

In industrial settings, hydraulic presses are the workhorses for shaping, forming, and assembling materials that require substantial force.

Metal Forming and Shaping

This is the most common use. Tasks include stamping flat metal sheets into parts like car doors, forging hot metal into strong components, deep drawing to create seamless containers, and bending thick plates.

Material Compacting and Molding

Hydraulic presses are essential for molding various materials. This includes compressing sheet molded composites (SMC), carbon fiber, and thermoplastics into lightweight, high-strength parts for the aerospace and automotive industries.

Assembling and Punching

The controlled force is also used for assembly operations like clinching, which joins sheets of metal without fasteners. They are also used for blanking and punching holes in thick, durable materials.

The Critical Role in Scientific Laboratories

While industrial presses are known for brute force, laboratory presses are valued for their precision and control in preparing and testing materials.

Sample Preparation for Analysis

Hydraulic presses are indispensable for preparing consistent, homogenous samples for spectroscopic analysis. They compress powders into dense KBr pellets for FTIR analysis or uniform sample pellets for XRF (X-ray fluorescence).

Materials Testing and Research

Scientists use laboratory presses to test the strength and durability of materials by applying precise, measurable loads. They are also used to investigate the effects of high pressure on different substances and for specialized tasks like hot embossing and creating thin polymer films.

Understanding the Trade-offs

While powerful, a hydraulic press is not always the best solution for every task. Its primary alternative is the mechanical press, and the choice involves clear trade-offs.

Advantage: Consistent and Controllable Force

A hydraulic press can deliver its full, rated force at any point in its stroke. This is critical for deep drawing or complex forming operations where consistent pressure is required throughout the process.

Advantage: Flexibility and Overload Safety

Hydraulic presses are not limited to a fixed stroke length and are protected from overload by pressure relief valves. This makes them more flexible and less prone to damage from being over-pressured.

Disadvantage: Speed

Mechanical presses, which operate with a crank and flywheel, are generally much faster. For high-volume, repetitive tasks like simple stamping, a mechanical press often provides higher throughput.

Disadvantage: Fluid Management

Because they rely on hydraulic fluid, these presses can be susceptible to leaks. The fluid also requires regular monitoring and maintenance to ensure clean and efficient operation.

Making the Right Choice for Your Application

Understanding these capabilities and trade-offs allows you to select the right tool for the job.

- If your primary focus is deep drawing, complex forming, or molding: A hydraulic press is the ideal choice for its consistent pressure and controllable stroke.

- If your primary focus is high-speed, repetitive stamping or punching: A mechanical press will likely offer better production speed and efficiency.

- If your primary focus is sample preparation or materials testing: A specialized laboratory hydraulic press is the essential tool for achieving precise, repeatable results.

Ultimately, the power of a hydraulic press lies in its direct and controllable application of fundamental physical principles.

Summary Table:

| Application Area | Key Uses |

|---|---|

| Industrial Manufacturing | Metal forging, stamping, deep drawing, molding composites (carbon fiber, SMC) |

| Scientific Laboratories | Preparing KBr pellets for FTIR, uniform pellets for XRF, materials testing |

| General Capabilities | Bending, punching, assembling, compacting with immense, controllable force |

Need a Press for Your Specific Application?

Whether you are forging industrial components or preparing precise laboratory samples, KINTEK's expertise ensures you get the right hydraulic press for your needs. Our lab equipment solutions deliver the precision and reliability required for accurate results.

Contact KINTEK today to discuss your project and discover the perfect press for your laboratory or manufacturing floor.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- What is the role of a laboratory hydraulic press in Al-doped LLZO pre-treatment? Ensure Dense Electrolyte Formation.

- Why should a hydraulic system always be started at low pressure? Prevent Catastrophic Failure and Ensure Safety

- Why is a laboratory hydraulic press used during the solid-state preparation of TiO2 catalysts? Optimize Doping Now

- Why KBr disc is used in IR spectroscopy? Achieve High-Resolution Analysis of Solid Samples

- What was the purpose of the hydraulic press? Harness Immense Force for Industrial and Lab Applications

- How does a laboratory hydraulic press ensure FM steel stability? Achieve Precise Thermomechanical Results

- What is the most likely cause of excessive temperature in the hydraulic fluid would be? A Faulty Relief Valve

- How does temperature affect forging? Master Hot, Cold, and Warm Forging for Optimal Results