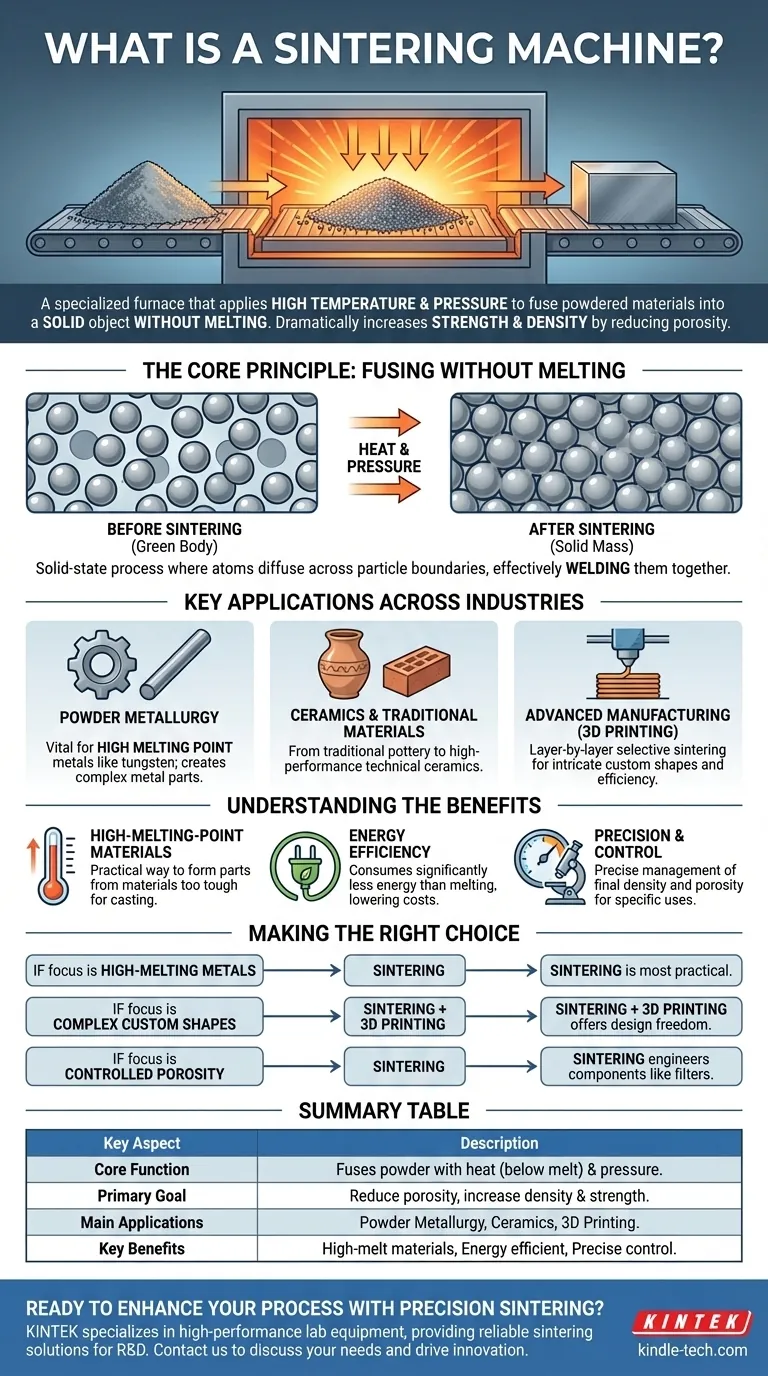

At its core, a sintering machine is a specialized furnace that applies high temperature and sometimes pressure to a powdered or loosely packed material. Its purpose is to fuse the individual particles together into a solid, coherent object without actually melting the material. This process, known as sintering, dramatically increases the material's strength and density by reducing the porous spaces between particles.

The crucial concept to grasp is that sintering is not melting. It's a solid-state process where a machine creates an environment hot enough to encourage atoms to diffuse across particle boundaries, effectively welding them together into a single, stronger piece.

The Core Principle: Fusing Without Melting

A sintering machine's entire function revolves around creating the precise conditions for atomic bonding. It manipulates temperature and pressure to fundamentally change a material's structure.

How It Works: Heat and Pressure

The machine heats a material to a temperature below its melting point. This thermal energy makes the atoms in the particles highly active, allowing them to migrate and bond with adjacent particles where they touch.

In some cases, pressure is also applied to physically compact the particles, increasing the points of contact and accelerating the fusion process.

The Goal: Reducing Porosity

The primary objective of sintering is to eliminate the empty voids between the individual grains of a loose powder. As particles fuse, these gaps shrink or close entirely.

This reduction in porosity is what gives the final product its density, strength, and improved material properties.

The Result: A Solid, Coherent Mass

The process transforms a "green body"—the initial, fragile shape made of loose particles—into a solid, durable component. The final object is a single, interconnected piece with significantly enhanced mechanical integrity.

Key Applications Across Industries

Sintering machines are foundational tools in numerous fields, particularly for materials that are difficult to work with using traditional melting and casting methods.

Powder Metallurgy

This is a primary application, used to create complex metal parts from powders. It's especially vital for metals with extremely high melting points, like tungsten, which are used for things like electrical wiring and cutting tools.

Other common sintered metal products include self-lubricating bearings, magnetic materials, and structural steel parts.

Ceramics and Traditional Materials

Sintering has been used for millennia to produce pottery, bricks, and other clay products. Modern applications extend this to high-performance ceramics, porcelain, and even glass production.

Advanced Manufacturing (3D Printing)

In modern additive manufacturing, sintering is used to create custom metal or ceramic parts layer by layer. A laser or other energy source selectively sinters powdered material, allowing for the creation of intricate shapes with remarkable energy efficiency and control.

Understanding the Benefits

Sintering is not just an alternative to melting; it offers unique advantages that make it the superior choice for many applications.

Benefit: Working with High-Melting-Point Materials

Sintering provides a practical way to form parts from materials whose melting points are too high for conventional casting, making it an indispensable industrial process.

Benefit: Energy Efficiency

Because the material is never fully melted, the sintering process consumes significantly less energy than traditional casting. This results in lower production costs, especially at scale.

Benefit: Precision and Control

The process allows for exceptional control over the final product's properties. By managing temperature, time, and pressure, manufacturers can precisely define the final density and porosity of a component, tailoring it for specific uses like filters or medical implants.

Making the Right Choice for Your Goal

The decision to use a sintering process is driven by the material you are working with and the desired properties of the final product.

- If your primary focus is creating parts from high-melting-point metals: Sintering is often the most practical and energy-efficient manufacturing method available.

- If your primary focus is manufacturing complex, custom metal shapes: Sintering, especially when combined with 3D printing, offers unparalleled design freedom and material control.

- If your primary focus is producing materials with controlled porosity: The sintering process allows you to precisely engineer components like filters or self-lubricating bearings.

Ultimately, a sintering machine enables the transformation of simple powders into sophisticated, high-performance components.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Function | Fuses powdered material particles into a solid mass using heat (below melting point) and sometimes pressure. |

| Primary Goal | Reduce porosity to increase density, strength, and improve material properties. |

| Main Applications | Powder Metallurgy, Ceramics, Advanced Manufacturing (3D Printing). |

| Key Benefits | Works with high-melting-point materials, Energy efficient, Offers precision and control over final properties. |

Ready to enhance your manufacturing process with precision sintering?

KINTEK specializes in high-performance lab equipment and consumables, providing reliable sintering solutions for laboratories and R&D departments. Whether you are developing new materials in powder metallurgy or advancing additive manufacturing techniques, our expertise can help you achieve superior part density and strength.

Contact us today to discuss how our sintering equipment can meet your specific laboratory needs and drive your innovations forward.

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- What is a sputtering machine? A Guide to High-Quality Thin Film Deposition

- How mechanical properties are affected by sintering? Master the Trade-offs for Stronger Materials

- What is a vacuum furnace? The Ultimate Guide to Contamination-Free Thermal Processing

- Why is sintering easier in the presence of a liquid phase? Unlock Faster, Lower-Temperature Densification

- Does sintering use diffusion? The Atomic Mechanism for Building Stronger Materials