In essence, a small hydraulic press is used for any task that requires a tremendous amount of controlled force in a compact space. These tools are masters of force multiplication, making them indispensable for shaping metal in a workshop, preparing samples in a laboratory, and testing the strength of materials.

A small hydraulic press is not just a tool for crushing; it is a device for precise transformation. Its core value lies in its ability to apply steady, controllable, and immense pressure, making it equally useful for a scientist creating a sample pellet partículas a craftsman forging a blade.

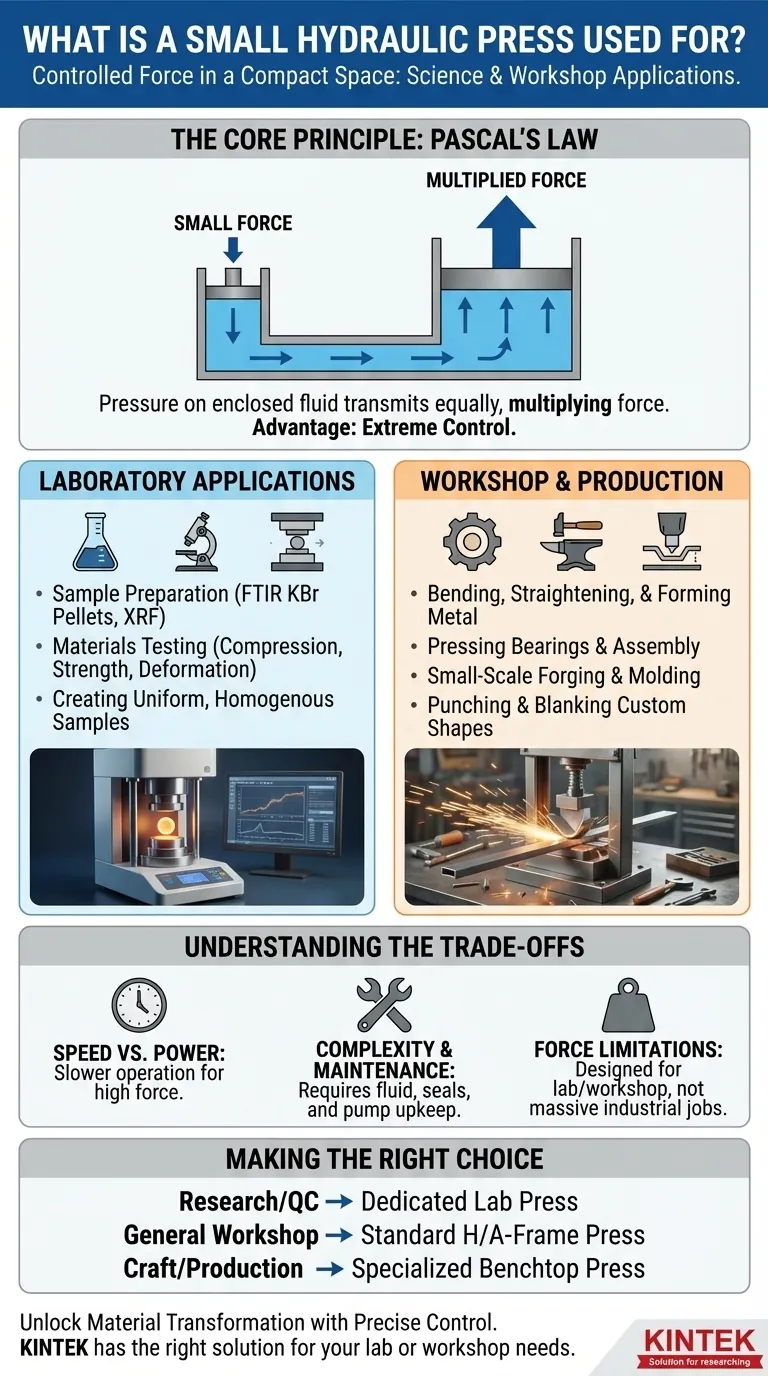

The Core Principle: Pascal's Law in Action

To understand its uses, you must first understand its power source. A hydraulic press operates on Pascal's principle, which states that pressure applied to an enclosed fluid is transmitted obstáculos throughout the fluid.

How It Works Simply

A small force is applied to a small piston, which pressurizes hydraulic fluid (usually oil). This pressure travels through the fluid and acts on a much larger piston, multiplying the initial force significantly.

This simple principle allows a small, often benchtop-sized, machine to generate many tons of force with minimal effort from the operator or a small motor.

The Critical Advantage: Control

Unlike a mechanical press that delivers force in a rapid stroke, a hydraulic press 움직이 slower and allows the force to be applied, held, and released with extreme precision. This control is vital for many of its most important applications.

Key Applications in the Laboratory

In scientific and quality control settings, the precise and powerful nature of a small hydraulic press is essential.

Sample Preparation for Analysis

Many analytical techniques, such as FTIR spectroscopy (using KBr pellets) and XRF (X-ray fluorescence), require samples to be in a solid, homogenous form. A lab press compacts loose powders into dense, uniform pellets or thin films.

This process ensures that the analytical measurement is consistent and representative of the entire sample, eliminating variables引入 by loose or uneven material.

Materials Science and Testing

Engineers and scientists use hydraulic presses to test the fundamental properties of materials. This includes compression testing to see how much умирает a material can withstand before deforming or failing, such as with concrete or ceramic samples.

They are also used to study how materials behave under extreme pressure, providing critical data for developing new alloys, polymers, and composites.

Essential Uses in the Workshop and Small-Scale Production

For fabricators, mechanics, and craftspeople, a small shop press инвестиция an invaluable tool for manipulating strong materials.

Bending, Forming, and Assembling

The most common use in a workshop is to bend, straighten, or shape metal parts. It is also the go-to tool for pressing bearings into or out of a housing, assembling tight-fitting components, or broaching keyways.

Small-Scale Forging and Molding

Artisans and bladesmiths use small presses for forging metal, offering a more controlled and less labor-intensive alternative to a hammer and anvil for умирает shaping and pattern welding.

These presses are also used for molding plastics, composites, and other materials in small-scale production or prototyping environments.

Punching and Blanking

With the right dies, a hydraulic press can cleanly punch holes or blank out custom shapes from sheet metal. The steady pressure aplicação a clean cut with minimal material deformation.

Understanding the Trade-offs

While incredibly versatile, hydraulic presses are not the solution for every problem. Understanding their limitations is key to using them effectively.

Speed vs. Power

The primary trade-off for a hydraulic press is speed. The same fluid dynamics that create immense force also mean the ram moves relatively slowly compared to a mechanical press. This makes them unsuitable for high-speed, high-volume stamping operations.

Complexity and Maintenance

Hydraulic systems involve fluid, pumps, hoses, and seals. While modern presses are highly reliable, they require maintenance and are susceptible to leaks if seals wear out. This adds a layer of complexity not found in simpler mechanical devices.

Force Limitations of Small Presses

A small benchtop or shop press, while powerful, has its limits. It is designed for workshop and lab-scale tasks, not for massive industrial jobs like crushing cars or large-scale forging, which require their enormous industrial counterparts.

Making the Right Choice for Your Goal

The "right" press depends entirely on your objective.

- If your primary focus is scientific research or quality control: You need a dedicated laboratory press designed for precise, repeatable pressure for sample preparation.

- If your primary focus is general workshop tasks: A standard H-frame or A-frame shop press is the most versatile choice for bending, straightening, and pressing components.

- If your primary focus is small-scale craft or production: Look for a benchtop press with features and a footprint tailored to your specific task, such as forging or molding.

Ultimately, a small hydraulic press empowers you to precisely control immense force, unlocking a wide range of material transformation possibilities.

Summary Table:

| Application Area | Primary Uses |

|---|---|

| Laboratory | Sample preparation (KBr pellets for FTIR), material compression testing, creating uniform samples for analysis. |

| Workshop & Production | Bending/straightening metal, pressing bearings, assembly, small-scale forging, punching, and blanking. |

Ready to harness the power of a hydraulic press for your projects?

Whether you are in a laboratory requiring precise sample preparation or a workshop needing reliable metal-forming capabilities, KINTEK has the right solution. We specialize in high-quality lab equipment and consumables, offering presses designed for accuracy, durability, and performance.

Contact our experts today to discuss your specific needs and discover how KINTEK can enhance your efficiency and results.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis