A quintessential example of a hydraulic system in industry is the hydraulic press. This machine uses a hydraulic cylinder to generate immense compressive force, making it fundamental for tasks like stamping, forging, and molding metal, plastic, or other materials into specific shapes.

Hydraulic systems are industry's go-to solution for force multiplication. By leveraging an incompressible fluid, they convert a small, manageable input force into a massive, controlled output force, enabling heavy-duty work that would otherwise be impossible.

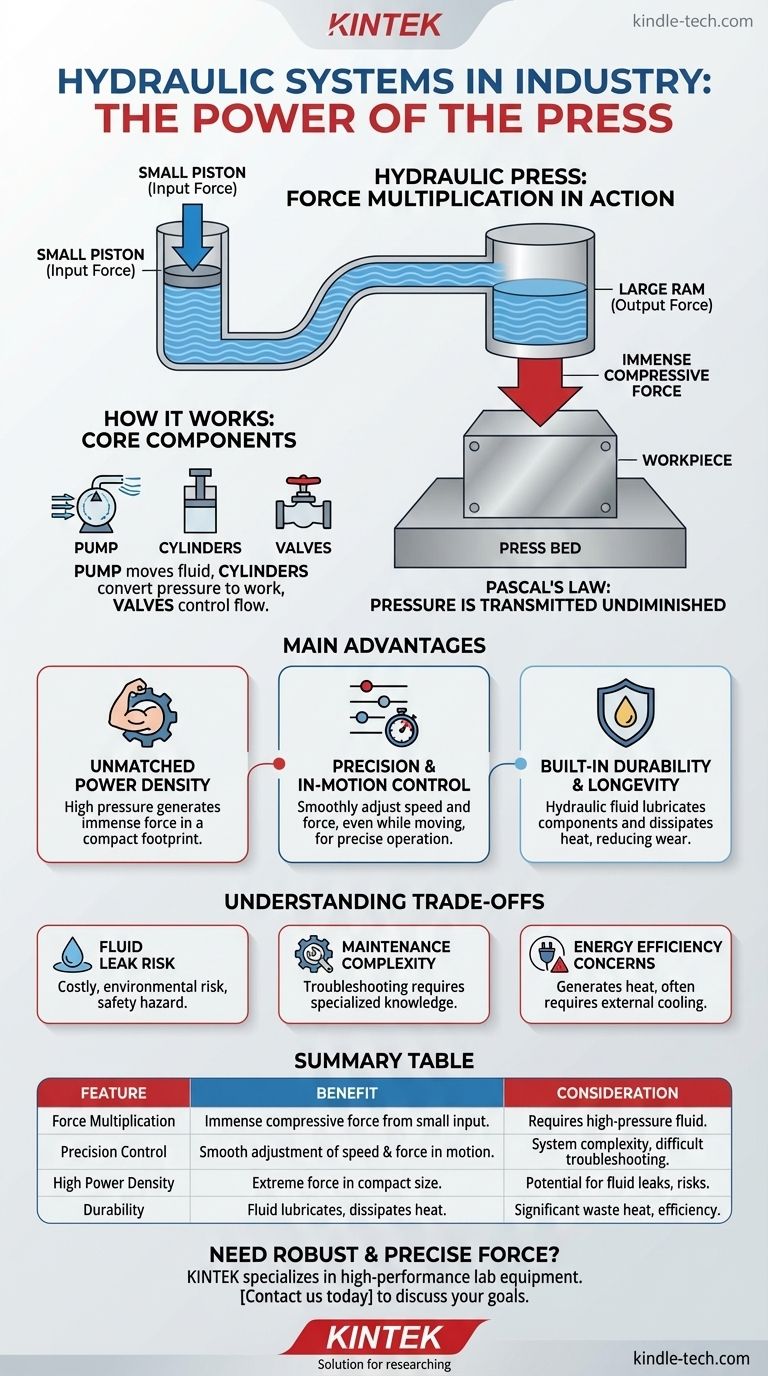

How a Hydraulic Press Works: The Core Principle

A hydraulic press is a powerful demonstration of fundamental fluid dynamics. Its operation hinges on a principle discovered centuries ago but applied on a massive scale in modern industry.

Pascal's Law in Action

The entire system is governed by Pascal's Law. This principle states that pressure applied to an enclosed, incompressible fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

The Force Multiplication Effect

This is the core of how a press generates extreme force. A small piston, driven by a motor-powered pump, applies pressure to the hydraulic fluid. Because this pressure is transmitted equally throughout the system, it acts on a much larger piston (the ram), multiplying the initial force significantly.

Key System Components

A typical industrial hydraulic system includes a pump to move the fluid, cylinders (pistons) to convert fluid pressure into mechanical work, valves to direct the flow and control speed, and the hydraulic fluid itself, which is almost always a specialized oil.

Why Industry Relies on Hydraulics

While the concept is simple, the practical benefits are what make hydraulics a cornerstone of heavy manufacturing and mobile machinery. The system's characteristics are perfectly suited for demanding environments.

Unmatched Power Density

Hydraulic systems can operate under extremely high pressure. This allows them to generate and withstand enormous forces within a relatively compact physical footprint, a concept known as high power density.

Precision and In-Motion Control

A key advantage is the ability to smoothly adjust the speed and force of the press ram, even while it is in motion. This is achieved by precisely regulating the fluid flow with valves, allowing for a high degree of control over the manufacturing process.

Built-in Durability and Longevity

The hydraulic oil serves multiple purposes. It not only transmits power but also lubricates all moving components and helps dissipate heat generated by high-pressure operation. This dual function protects the system, reduces wear, and contributes to a very long service life.

Understanding the Trade-offs

Despite their power, hydraulic systems are not the solution for every problem. Understanding their limitations is crucial for proper application.

The Risk of Fluid Leaks

The biggest operational challenge is the potential for hydraulic fluid leaks. Leaks are costly, create significant slip-and-fall hazards for personnel, pose an environmental contamination risk, and can lead to system-wide performance degradation or failure.

Maintenance Complexity

While components are durable, the overall system can be complex. Troubleshooting issues like pressure drops or slow operation often requires specialized knowledge of fluid dynamics and the specific system's schematics.

Energy Efficiency Concerns

Hydraulic systems can generate significant waste heat under continuous, heavy load. While the fluid helps manage this, external coolers are often necessary, which adds to the system's energy consumption and lowers overall efficiency compared to some electromechanical alternatives.

Making the Right Choice for Your Goal

Selecting the correct technology—be it hydraulic, pneumatic, or electromechanical—depends entirely on the specific requirements of the industrial task.

- If your primary focus is immense force and power density: Hydraulics are the unparalleled choice for applications like metal forming, stamping, heavy lifting, and demolition.

- If your primary focus is high-speed, low-force repetitive motion: A pneumatic (air-powered) or electromechanical system is often more efficient and cleaner for tasks like rapid assembly or packaging.

- If your primary focus is cleanliness and simple control: Electromechanical actuators are often preferred in environments like food processing or medical device manufacturing where any risk of fluid leakage is unacceptable.

Ultimately, understanding the core principles of force multiplication allows you to recognize why hydraulics remain the workhorse for the world's most demanding industrial jobs.

Summary Table:

| Feature | Benefit | Consideration |

|---|---|---|

| Force Multiplication | Generates immense compressive force from a small input. | Requires high-pressure fluid. |

| Precision Control | Speed and force can be adjusted smoothly, even in motion. | System complexity can make troubleshooting difficult. |

| High Power Density | Delivers extreme force in a compact footprint. | Potential for fluid leaks, posing safety and environmental risks. |

| Durability | Hydraulic fluid lubricates components and dissipates heat. | Can generate significant waste heat, impacting energy efficiency. |

Need robust and precise force for your lab or production line? KINTEK specializes in high-performance lab equipment and consumables, serving diverse laboratory needs. Whether your process requires the immense power of a hydraulic press or another specialized solution, our experts can help you select the ideal technology for your application. Contact us today to discuss how we can enhance your operational efficiency and achieve your manufacturing goals.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.