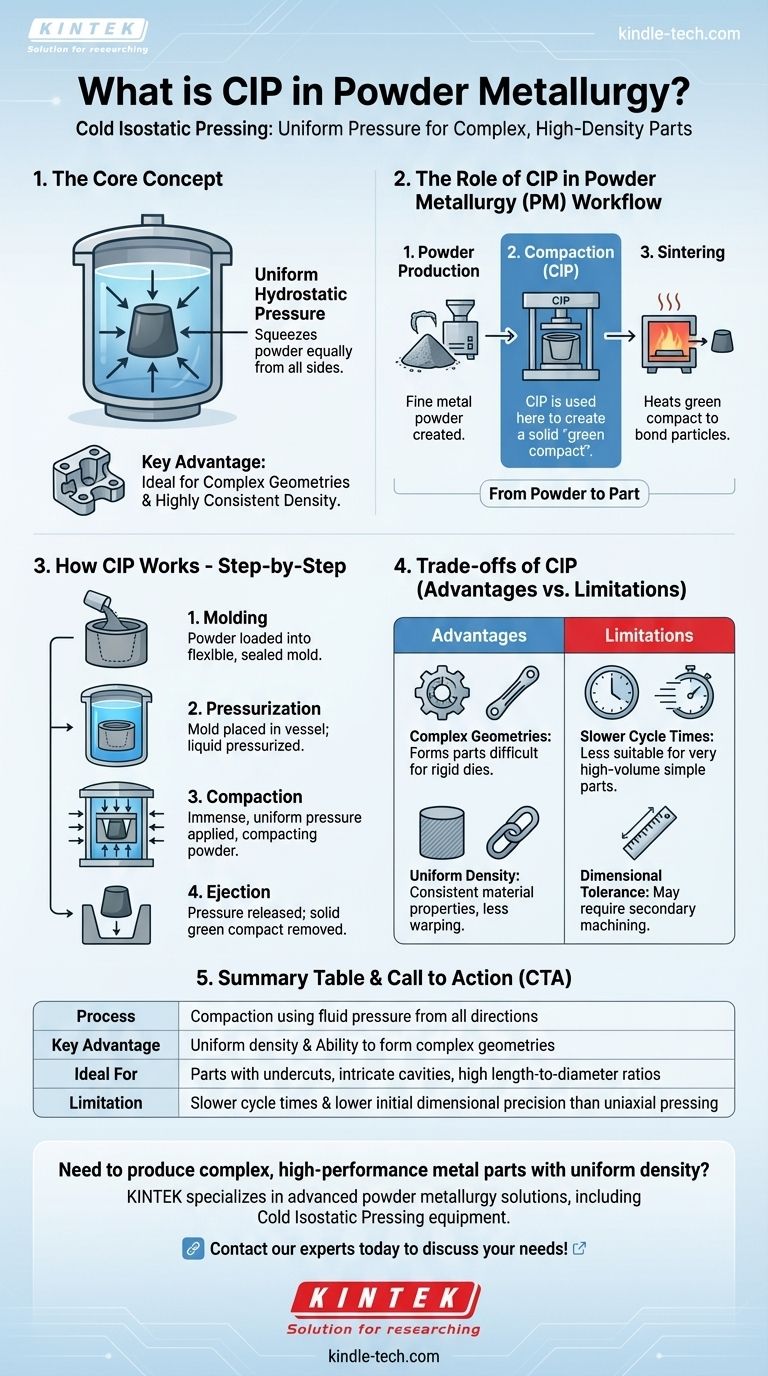

In powder metallurgy, Cold Isostatic Pressing (CIP) is a compaction method that uses fluid pressure to uniformly compress metal powder into a solid shape before the final sintering stage. This process is used to create a preliminary object, known as a "green compact," which has enough structural integrity to be handled.

The central advantage of CIP is its use of uniform, hydrostatic pressure. Unlike traditional presses that apply force in one direction, CIP squeezes the powder equally from all sides, making it uniquely capable of forming complex parts with highly consistent density.

The Role of CIP in the Powder Metallurgy Process

To understand CIP, you must first understand its place within the broader powder metallurgy (PM) workflow. The PM process fundamentally consists of three core stages.

From Powder to Part: The Core Steps

First, a fine metal powder is produced through methods like atomization or chemical reaction. This raw material is the foundation of the final part.

Second, the loose powder is compacted into a desired shape. This is the stage where Cold Isostatic Pressing is employed. The goal is to create a fragile but solid object, the "green compact."

Finally, the green compact is heated in a controlled-atmosphere furnace to a temperature below its melting point. This process, known as sintering, bonds the metal particles together, giving the part its final strength and properties.

How Cold Isostatic Pressing Actually Works

The effectiveness of CIP comes from its unique application of pressure. It bypasses the limitations of conventional mechanical presses by using a liquid medium to do the work.

The "Isostatic" Principle

The key is the term isostatic, which means "uniform pressure in all directions." Imagine squeezing an object in a mechanical vise—the pressure is only applied from two sides.

Now, imagine submerging that object deep in the ocean. The water pressure acts on its entire surface equally. This is the principle behind CIP. The liquid acts as a perfect medium to transmit pressure evenly onto every surface of the powder mass.

The CIP Process Step-by-Step

- Molding: The metal powder is loaded into a flexible, sealed mold, typically made of rubber, urethane, or PVC. This mold defines the shape of the part.

- Pressurization: The sealed mold is placed inside a high-pressure vessel filled with a liquid (usually water or oil).

- Compaction: The liquid is pressurized, applying immense, uniform pressure to the outside of the flexible mold. This compacts the powder inside into a solid mass.

- Ejection: The pressure is released, and the mold containing the now-solid green compact is removed from the vessel.

The Result: A Uniform Green Compact

The output is a part with remarkably uniform density. Because the pressure was applied from all sides, there are no weak spots or density gradients that can occur with one-directional pressing, which is critical for performance in the final sintered part.

Understanding the Trade-offs of CIP

While powerful, CIP is not the universal solution for all powder compaction. Its benefits come with specific limitations that make it suitable for certain applications and not others.

Key Advantage: Complex Geometries

CIP excels at producing shapes that are difficult or impossible to make with rigid dies. This includes parts with undercuts, intricate internal cavities, or high length-to-diameter ratios.

Key Advantage: Uniform Density

The uniform pressure ensures that the material properties throughout the part are consistent. This minimizes warping during sintering and improves the mechanical performance of the final component.

Limitation: Slower Cycle Times

The process of loading the mold, sealing it, placing it in the vessel, pressurizing, and de-pressurizing is inherently slower than the rapid stamping motion of a mechanical press. This makes CIP less suitable for very high-volume production of simple parts.

Limitation: Dimensional Tolerance

While the shape is complex, the initial dimensional precision can be lower than that of rigid die compaction. The flexible mold can deform slightly, meaning parts made via CIP often require secondary machining to meet tight tolerances.

Making the Right Choice for Your Goal

Selecting the correct compaction method depends entirely on the part's geometry, required performance, and production volume.

- If your primary focus is high-volume production of simple shapes: Traditional uniaxial (single-direction) die compaction is almost always more cost-effective and faster.

- If your primary focus is creating parts with complex internal or external geometries: CIP is one of the best methods available for forming the initial green compact.

- If your primary focus is achieving maximum material uniformity and minimizing defects: CIP provides superior density consistency, leading to a higher-quality final product after sintering.

By understanding its unique ability to apply uniform pressure, you can leverage CIP as a powerful tool for manufacturing advanced and complex components.

Summary Table:

| Feature | Description |

|---|---|

| Process | Compaction using fluid pressure from all directions |

| Key Advantage | Uniform density and ability to form complex geometries |

| Ideal For | Parts with undercuts, intricate cavities, or high length-to-diameter ratios |

| Limitation | Slower cycle times and lower initial dimensional precision than uniaxial pressing |

Need to produce complex, high-performance metal parts with uniform density?

KINTEK specializes in advanced powder metallurgy solutions, including Cold Isostatic Pressing equipment and consumables. Our expertise helps laboratories and manufacturers achieve superior material consistency and form intricate geometries efficiently.

Contact our experts today to discuss how our CIP technology can enhance your R&D or production process!

Visual Guide

Related Products

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- What advantages does Cold Isostatic Pressing (CIP) offer for nickel-alumina composites? Enhance Density & Strength

- What temperature is cold isostatic pressing? A Guide to Room-Temperature Powder Compaction

- What is the process of cold isostatic pressing? Achieve Uniform Density in Complex Parts

- What is cold isostatic pressing of metal powder? Achieve Uniform Density in Complex Metal Parts

- What role does a Cold Isostatic Press (CIP) play in aluminum matrix composites? Achieve 90% Density for Better Hot Pressing