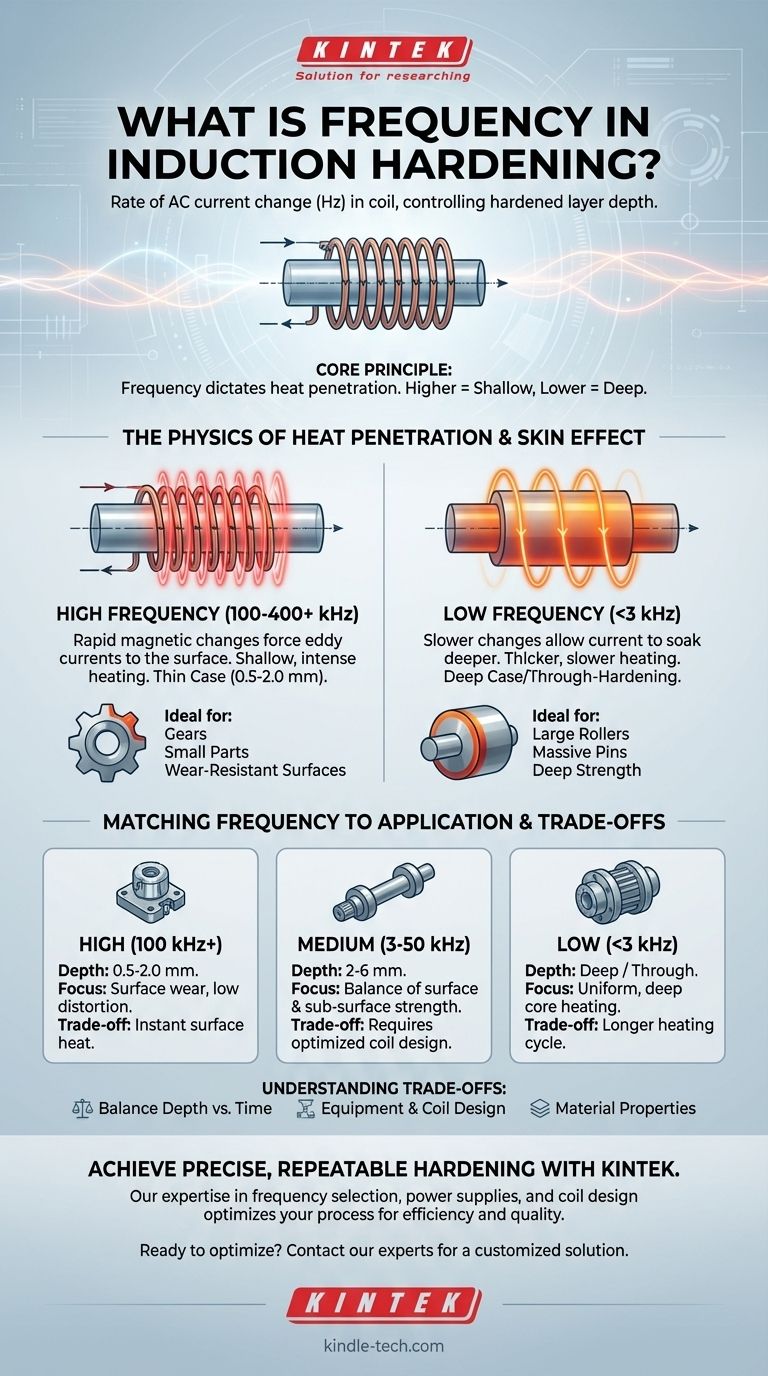

In induction hardening, frequency refers to the rate at which the alternating electrical current changes direction within the induction coil. This rate, measured in Hertz (Hz), is a critical control parameter. It directly dictates how the induced magnetic field generates heat within the metal part, making it the primary factor in determining the depth of the hardened layer.

The core principle to understand is the relationship between frequency and heat penetration. Higher frequencies concentrate heat near the surface for a shallow hardening effect, while lower frequencies penetrate deeper into the material for a thicker hardened case.

The Physics of Frequency and Heat Penetration

To understand induction hardening, you must first understand the "skin effect." This phenomenon is the foundation for why frequency is such a powerful tool.

Understanding the Skin Effect

When an alternating current (AC) flows through a conductor, like the metal part you are hardening, it does not distribute itself evenly across the entire cross-section. Instead, it tends to concentrate on the outer surface or "skin" of the conductor.

The rapid magnetic field changes created by the AC in the induction coil induce opposing currents (eddy currents) in the workpiece. These eddy currents are strongest at the surface and are responsible for the vast majority of the resistive heating.

How Frequency Governs the Skin Effect

The frequency of the alternating current directly governs the intensity of the skin effect.

As you increase the frequency, the magnetic field changes direction more rapidly. This forces the induced eddy currents into an even thinner layer at the surface, causing extremely rapid and concentrated heating in that shallow region.

Conversely, as you decrease the frequency, the current has more time to "soak" deeper into the material before it reverses direction. This results in a thicker heated layer and deeper heat penetration.

The Concept of "Reference Depth"

Engineers quantify this phenomenon using the term reference depth (or penetration depth). This is the depth at which the induced current density drops to approximately 37% of its value at the surface.

This reference depth provides a reliable guideline for the minimum possible hardening depth you can achieve at a given frequency. The final case depth is also influenced by heating time and power, but frequency sets the fundamental limit.

Matching Frequency to Your Application

The choice of frequency is not arbitrary; it is selected based on the desired metallurgical outcome for a specific part. Frequencies are typically grouped into three main ranges.

High-Frequency Hardening (100 kHz – 400 kHz+)

High frequencies are used for applications requiring a thin, wear-resistant case on the part's surface, typically from 0.5 to 2.0 mm.

This is ideal for small parts or parts with intricate geometries, such as gear teeth, where you need to harden only the functional surface without distorting the core of the part. The heating is extremely fast and localized.

Medium-Frequency Hardening (3 kHz – 50 kHz)

Medium frequencies provide a balance, achieving deeper case depths of approximately 2 to 6 mm.

This range is the workhorse for many industrial components, such as automotive axles, large shafts, and crane wheels, where both surface hardness and significant sub-surface strength are required to handle high stress.

Low-Frequency Hardening (Below 3 kHz)

Low frequencies are used for deep case hardening or "through-hardening" on very large components. The goal here is to heat the part deeply and uniformly.

Applications include hardening large rollers for steel mills or large-diameter pins where hardness is required well into the core of the material to support massive loads.

Understanding the Trade-offs

Selecting a frequency involves balancing competing factors. It is not simply a matter of choosing "high" or "low."

Depth vs. Heating Time

There is a direct trade-off between penetration depth and the time it takes to heat the surface. High frequencies heat the surface almost instantly, while lower frequencies require a longer heating cycle to allow the energy to penetrate deeper.

Equipment and Coil Design

The operating frequency dictates the required equipment. A high-frequency power supply is fundamentally different from a low-frequency one. Furthermore, the design of the induction coil itself is closely tied to the frequency and the part geometry to ensure efficient energy transfer. You cannot simply use any coil with any frequency.

Material Properties

The material's electrical resistivity and magnetic properties also influence heating efficiency. For example, steel is magnetic below its Curie temperature (around 770°C), which significantly increases heating efficiency. Once it becomes non-magnetic, the efficiency drops. This dynamic must be accounted for in the process design.

Making the Right Choice for Your Hardening Goal

Your final decision should be driven entirely by the metallurgical requirements of the component.

- If your primary focus is a thin, wear-resistant surface on a complex part (like a gear tooth): Use high frequencies (100 kHz and above) to concentrate heat precisely on the surface and minimize part distortion.

- If your primary focus is a robust, deep case on a structural component (like an axle): Use medium frequencies (3 kHz to 50 kHz) to achieve a good balance of surface hardness and deep strength.

- If your primary focus is achieving uniform, through-hardening on a very large cross-section: Select low frequencies (below 3 kHz) to allow the heat to penetrate deep into the core of the material.

Ultimately, mastering frequency selection is the key to unlocking precise, repeatable control over the induction hardening process.

Summary Table:

| Frequency Range | Typical Case Depth | Ideal Applications |

|---|---|---|

| High (100 kHz+) | 0.5 - 2.0 mm | Gear teeth, small components, wear-resistant surfaces |

| Medium (3 - 50 kHz) | 2.0 - 6.0 mm | Axles, shafts, crane wheels, structural components |

| Low (Below 3 kHz) | Deep case / Through-hardening | Large rollers, pins, massive components |

Achieve precise, repeatable hardening results for your components.

Selecting the right frequency is critical for achieving the exact case depth and metallurgical properties your parts require. KINTEK specializes in providing advanced induction hardening solutions, including power supplies and coil designs optimized for your specific application—from high-frequency surface hardening of intricate gears to deep case hardening of large structural parts.

Our expertise ensures you get the right equipment and process parameters to maximize efficiency, minimize distortion, and meet your quality standards.

Ready to optimize your induction hardening process? Contact our experts today for a customized solution.

Visual Guide

Related Products

- Small Injection Molding Machine for Lab Use

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Anti-Cracking Press Mold for Lab Use

- Double Plate Heating Press Mold for Lab

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is short capacity of injection Moulding machine? Optimize Your Shot Size for Flawless Parts

- What is a positive of injection moulding? Achieve High-Volume Production with Unmatched Efficiency

- What is the manufacturing process of rubber molding? Injection, Compression, or Transfer Molding?

- What is molding technique? A Guide to High-Volume, Complex Part Manufacturing

- What are the parameters to be considered for selecting the thin wall molding machine? Key Specs for High-Speed Production