Hot Isostatic Pressing (HIP) "welding" is a solid-state joining method more accurately known as diffusion bonding. Rather than melting materials with an arc or flame, this process uses a combination of intense, uniform pressure and high temperature in an inert atmosphere. This forces the atoms of two separate components to inter-diffuse, creating a seamless, metallurgical bond at the interface without ever entering a liquid phase.

The core difference is that traditional welding melts and fuses materials, creating a distinct joint and a heat-affected zone. HIP diffusion bonding forges two components into a single, monolithic piece on an atomic level, often resulting in a joint that is as strong as the parent material itself.

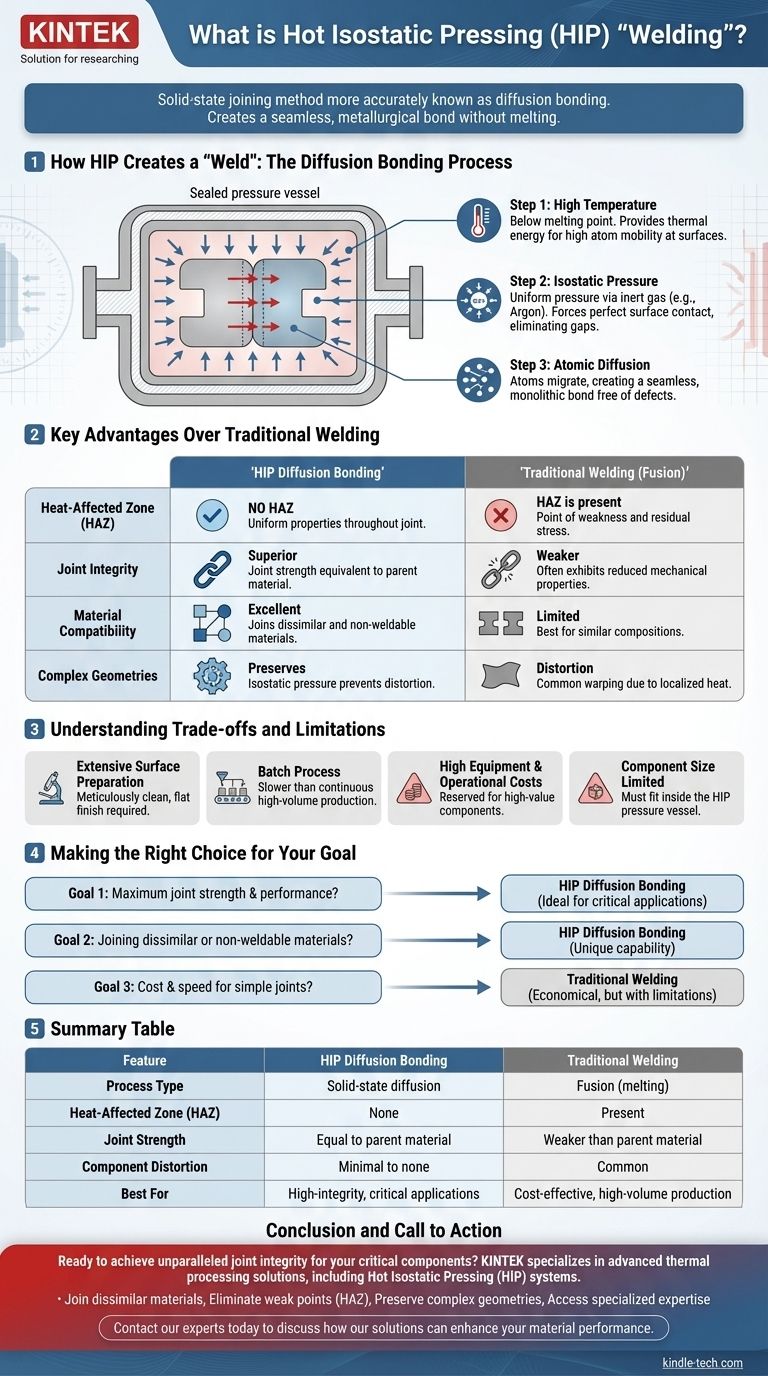

How HIP Creates a "Weld": The Diffusion Bonding Process

HIP achieves this unique solid-state joining through the precise control of three key factors: temperature, pressure, and atmosphere. The components to be joined are placed in intimate contact inside a sealed pressure vessel.

The Role of High Temperature

The vessel is heated to a temperature below the melting point of the materials. This elevated temperature provides the thermal energy necessary to make the atoms at the surface of each component highly mobile.

The Role of Isostatic Pressure

Simultaneously, the vessel is filled with a high-pressure inert gas, typically Argon. This "isostatic" pressure is uniform, meaning it applies equal force from all directions. This immense pressure forces the two mating surfaces into perfect, intimate contact, eliminating any microscopic gaps or voids between them.

The Result: Atomic Diffusion

With the surfaces held in perfect contact by the pressure and the atoms energized by the heat, atoms begin to migrate across the boundary between the two components. Over the course of the process, this diffusion creates a bond that is metallurgically seamless and free of defects.

Key Advantages Over Traditional Welding

Using HIP for diffusion bonding offers significant advantages for critical applications where the integrity of the joint is paramount.

No Melting or Heat-Affected Zone (HAZ)

Because the material never melts, HIP avoids the creation of a Heat-Affected Zone (HAZ). The HAZ in traditional welds is often a point of mechanical weakness, residual stress, and reduced corrosion resistance. HIP-bonded parts have uniform material properties right through the joint.

Superior Joint Integrity

The diffusion bonding process creates a true metallurgical bond. The resulting joint can exhibit mechanical properties, such as tensile strength and fatigue resistance, that are equivalent to the parent materials.

Joining Dissimilar and Non-Weldable Materials

HIP is exceptionally effective at joining materials with very different chemical compositions or melting points that are impossible to join with conventional fusion welding. This allows for the creation of hybrid components with unique property combinations.

Preserving Complex Geometries

The uniform, isostatic nature of the pressure ensures that components are not distorted or warped during the process. This is critical when joining pre-machined, high-precision parts with complex shapes or internal channels.

Understanding the Trade-offs and Limitations

While powerful, HIP diffusion bonding is not a universal replacement for all welding processes. It has specific requirements and constraints that make it suitable for certain applications.

Extensive Surface Preparation is Critical

For atomic diffusion to occur, the mating surfaces must be meticulously clean and machined to have a very fine, flat finish. Any surface oxides or contaminants will act as a barrier and prevent a successful bond.

A Batch Process, Not Continuous

Components must be loaded into a HIP vessel, processed for several hours, and then cooled before removal. This batch nature makes it less suitable for high-volume, continuous production lines compared to automated arc welding.

High Equipment and Operational Costs

HIP systems are significant capital investments, and the operational costs associated with high pressures, temperatures, and inert gas consumption are considerable. This tends to reserve the process for high-value components.

Component Size is Limited

The parts being joined must be able to fit inside the HIP pressure vessel, which limits the maximum size of the final assembly.

Making the Right Choice for Your Goal

Selecting the correct joining process requires matching the method's capabilities to your primary engineering objective.

- If your primary focus is maximum joint strength and performance: HIP diffusion bonding is ideal for creating joints that are indistinguishable from the parent material, eliminating the weak points of traditional welds.

- If your primary focus is joining dissimilar or non-weldable materials: HIP provides a unique capability to create strong, solid-state bonds between alloys that cannot be joined by fusion welding.

- If your primary focus is cost and speed for simple joints: Traditional welding methods are almost always more economical and faster for applications where a heat-affected zone and some distortion are acceptable.

By understanding its principles, you can leverage HIP to solve complex manufacturing challenges that are impossible with conventional joining methods.

Summary Table:

| Feature | HIP Diffusion Bonding | Traditional Welding |

|---|---|---|

| Process Type | Solid-state diffusion | Fusion (melting) |

| Heat-Affected Zone (HAZ) | None | Present |

| Joint Strength | Equal to parent material | Weaker than parent material |

| Material Compatibility | Excellent for dissimilar materials | Limited |

| Component Distortion | Minimal to none | Common |

| Best For | High-integrity, critical applications | Cost-effective, high-volume production |

Ready to achieve unparalleled joint integrity for your critical components?

KINTEK specializes in advanced thermal processing solutions, including Hot Isostatic Pressing (HIP) systems. Our expertise in lab equipment and consumables is tailored to meet the demanding needs of laboratories and manufacturers working with high-performance materials.

By partnering with KINTEK, you can:

- Join dissimilar or non-weldable materials with confidence

- Eliminate weak points like heat-affected zones (HAZ)

- Preserve complex geometries with uniform isostatic pressure

- Access specialized expertise for your most challenging material joining applications

Let us help you solve complex manufacturing challenges with HIP technology. Contact our experts today to discuss how our solutions can enhance your material performance and product reliability.

Visual Guide

Related Products

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Anti-Cracking Press Mold for Lab Use

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

People Also Ask

- How does a laboratory hydraulic press contribute to MIC testing? Ensure Precision in Stainless Steel Specimens

- What is the process of mounting in metallurgy? A Guide to Perfect Specimen Preparation

- What is the purpose of using epoxy resin and laboratory mounting equipment? Precision in U71Mn Weld Area Analysis

- What is the general procedure and what precautions should be taken during the polishing process? Achieve a Flawless Electrode Finish

- What is the difference between hot mounting and cold mounting? Choose the Right Method for Your Sample