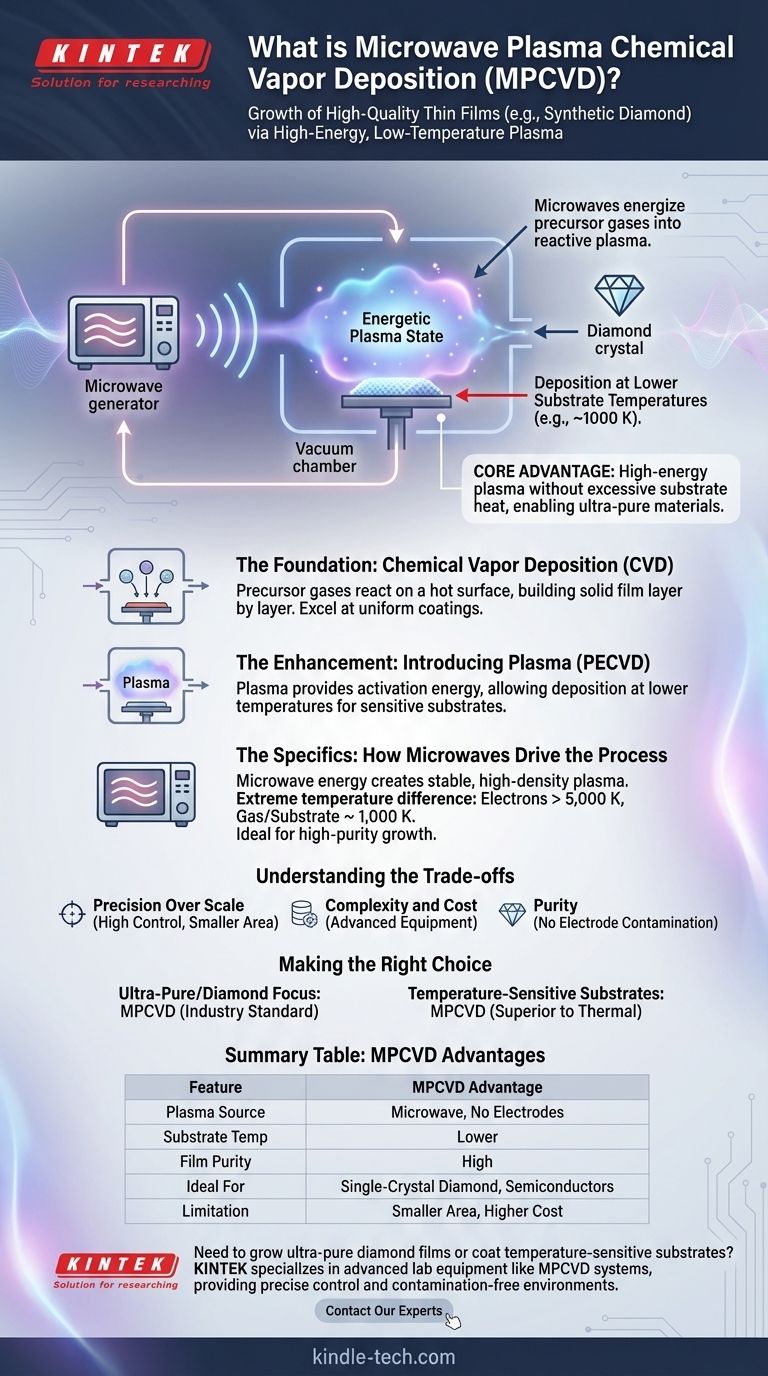

In essence, Microwave Plasma Chemical Vapor Deposition (MPCVD) is a highly specialized process used to grow high-quality thin films, most notably synthetic diamond. It works by using microwave radiation to energize precursor gases into a plasma state within a vacuum chamber, creating the ideal chemical environment for atoms to arrange themselves into a crystalline film on a substrate.

The core advantage of MPCVD is its ability to create a high-energy, reactive plasma without requiring excessively high substrate temperatures. This unique combination allows for the deposition of ultra-pure materials that are difficult or impossible to create using other methods.

The Foundation: Understanding Chemical Vapor Deposition (CVD)

To understand MPCVD, we must first understand its parent technology, Chemical Vapor Deposition (CVD).

The Core Principle of CVD

At its heart, CVD is a process where a substrate (the workpiece) is placed inside a reaction chamber. Volatile chemical gases, known as precursors, are then introduced into the chamber.

These gases react or decompose on the hot substrate's surface, leaving behind a solid material deposit. This builds up layer by layer, forming a thin, solid film.

Key Advantages of CVD

CVD is widely used because it excels at creating uniform coatings, even on complex, non-flat surfaces. This overcomes the "line-of-sight" limitation of other methods like Physical Vapor Deposition (PVD).

It is also an economically efficient method for creating thick, durable coatings for applications ranging from electronics and solar cells to corrosion-resistant cutting tools.

The Enhancement: Introducing Plasma

MPCVD is a form of Plasma-Enhanced Chemical Vapor Deposition (PECVD). The introduction of plasma is what fundamentally changes the process.

What is Plasma's Role?

Plasma is often called the fourth state of matter. It's a gas that has been energized to the point where its atoms are broken apart into a mix of electrons, ions, and highly reactive molecular fragments called radicals.

In CVD, this plasma provides the energy needed to kickstart the chemical reactions. Instead of relying solely on heat, the energetic plasma dissociates the precursor gases far more efficiently.

The Benefit of Lower Temperatures

Because the plasma provides the activation energy, the substrate itself does not need to be heated to extreme temperatures.

This is a critical advantage. It allows for the deposition of high-quality films onto a wider range of materials, including those that would be damaged or melted by traditional high-temperature thermal CVD processes.

The Specifics: How Microwaves Drive the Process

The "Microwave" in MPCVD refers to the specific energy source used to create and sustain the plasma.

Generating the Plasma

In an MPCVD system, microwave radiation (similar to that in a microwave oven, but much more powerful and focused) is directed into the chamber. This energy is absorbed by the precursor gases, stripping electrons from the atoms and creating a stable, high-density plasma.

A Unique High-Energy, Low-Temperature Environment

The most distinct feature of MPCVD is the extreme temperature difference it creates. The free electrons in the plasma can reach temperatures over 5,000 K, while the overall gas and substrate temperature remains much lower, often around 1,000 K.

This creates a highly reactive environment filled with the specific chemical species needed for growth (like carbon and atomic hydrogen for diamond synthesis) without transferring excessive, damaging heat to the substrate. This is why MPCVD is the premier method for growing high-purity, single-crystal diamond.

Understanding the Trade-offs

While powerful, MPCVD is not a universal solution. It is a specialized tool with specific advantages and limitations.

Precision Over Scale

MPCVD systems are engineered for high control and purity, not necessarily mass production. The deposition area is often smaller compared to large-batch thermal CVD reactors, making it more suitable for high-value applications rather than large-area commodity coatings.

Complexity and Cost

The equipment required for MPCVD—including the microwave generator, vacuum chamber, and control systems—is complex and carries a higher capital cost than simpler methods like Hot-Filament CVD (HFCVD) or thermal CVD.

Purity vs. Contamination

A key advantage of MPCVD over a method like HFCVD is its purity. Because the plasma is generated without electrodes or filaments inside the chamber, the risk of contaminants from the equipment itself entering the film is virtually eliminated.

Making the Right Choice for Your Goal

Selecting a deposition method requires aligning the technology's strengths with your primary objective.

- If your primary focus is ultra-pure, single-crystal films like gem-quality diamond or high-performance semiconductors: MPCVD is the industry standard due to its clean, highly controlled, and energetic plasma environment.

- If your primary focus is coating temperature-sensitive substrates: Any PECVD method, including MPCVD, is superior to high-temperature thermal processes.

- If your primary focus is economical, large-area industrial coatings where ultimate purity is not the top priority: Traditional Thermal CVD or other large-scale PECVD systems may be a more cost-effective choice.

Ultimately, understanding the role of the energy source—be it thermal, filament-based, or microwave-driven plasma—is the key to selecting the ideal deposition technology for your material.

Summary Table:

| Feature | MPCVD Advantage |

|---|---|

| Plasma Source | Microwave energy, no internal electrodes |

| Substrate Temperature | Lower (enables coating of sensitive materials) |

| Film Purity | High (no filament contamination) |

| Ideal For | Single-crystal diamond, high-purity semiconductors |

| Limitation | Smaller deposition area, higher equipment cost |

Need to grow ultra-pure diamond films or coat temperature-sensitive substrates? KINTEK specializes in advanced lab equipment like MPCVD systems, providing the precise control and contamination-free environment essential for high-quality material deposition. Contact our experts today to discuss how our solutions can meet your specific laboratory needs.

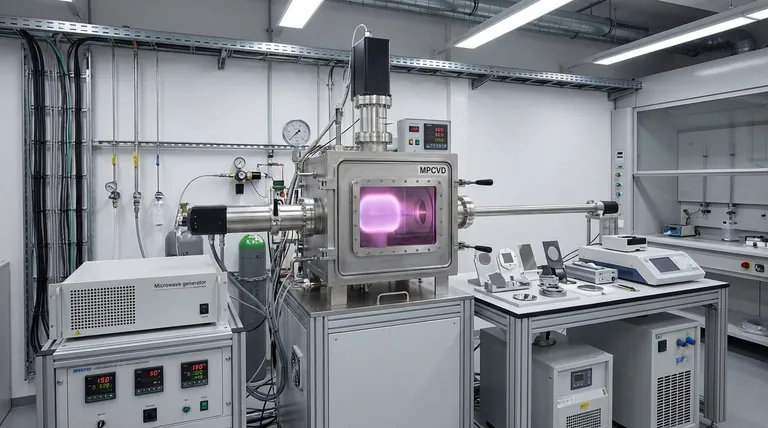

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Spark Plasma Sintering Furnace SPS Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the main advantages of Chemical Vapor Deposition (CVD)? Achieve Precision Coating for Complex Geometries

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- What are the methods of producing CNT? Scalable CVD vs. High-Purity Lab Techniques

- What role does Chemical Vapor Deposition (CVD) equipment play in the preparation of C/C composites? Expert Analysis