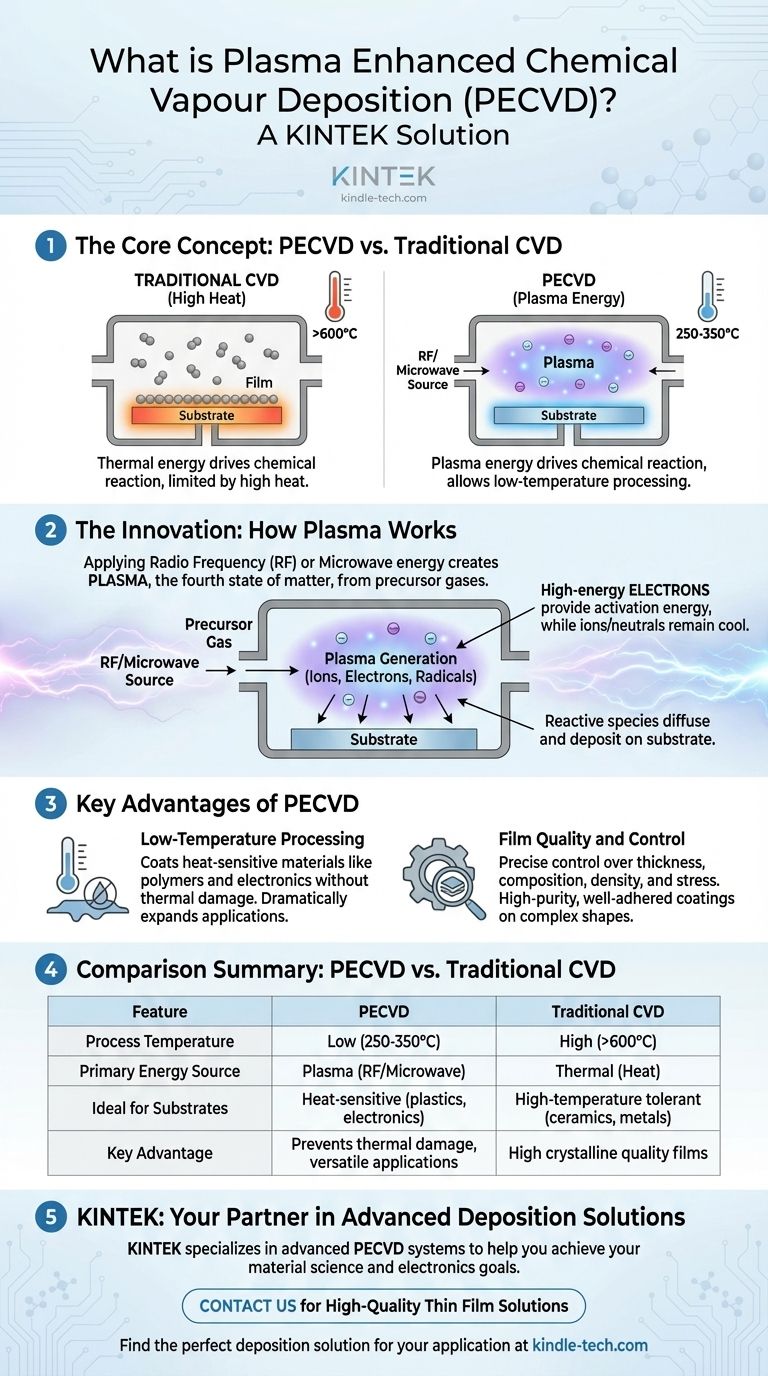

In the world of advanced materials, Plasma Enhanced Chemical Vapor Deposition (PECVD) is a method for depositing high-quality thin films onto a surface using an energized gas, or plasma, instead of extreme heat. This technique uses the energy from the plasma to initiate the chemical reactions needed to form the film, allowing the process to occur at significantly lower temperatures than traditional Chemical Vapor Deposition (CVD).

The fundamental advantage of PECVD is its ability to overcome the high-temperature barrier of conventional methods. This allows for the coating of heat-sensitive materials, such as plastics and complex electronics, without causing thermal damage, dramatically expanding the applications for advanced thin films.

The Foundation: Understanding Traditional CVD

The Core Principle: A Chemical Reaction

Traditional Chemical Vapor Deposition (CVD) involves introducing precursor gases into a vacuum chamber containing the object to be coated, known as the substrate.

The chamber is heated to a very high temperature, often several hundred degrees Celsius. This thermal energy "cracks" the gas molecules, causing a chemical reaction on the substrate's surface that deposits a solid, thin film.

The Key Limitation: The Need for High Heat

The reliance on high heat is the primary constraint of traditional CVD. Many advanced materials, including polymers, plastics, and fully assembled electronic components, cannot withstand such temperatures.

Attempting to coat these substrates with traditional CVD would lead to melting, warping, or complete destruction of the underlying component.

The Innovation: How Plasma Changes the Game

Generating an Energized State

PECVD circumvents the need for high heat by creating a plasma, often described as the fourth state of matter. This is achieved by applying energy—typically from a radio frequency (RF) or microwave source—to the precursor gas inside the chamber.

This process strips electrons from the gas atoms, creating a highly reactive environment filled with ions, electrons, radicals, and other molecular fragments.

Energy Transfer, Not Just Heat

The key to PECVD is that the plasma itself is not uniformly hot. While the free electrons within the plasma can reach temperatures of thousands of degrees, the gas ions and neutral particles remain relatively cool.

It is the high-energy electrons that collide with and transfer energy to the precursor gas molecules. This provides the activation energy needed to break chemical bonds and initiate the deposition reaction, all while the substrate itself remains at a much lower temperature (e.g., 250-350°C).

The Deposition Process

Once the reactive species are generated in the plasma, they diffuse toward the substrate. They then adsorb onto the surface and undergo the necessary chemical reactions to form a dense, high-purity film, just as in traditional CVD.

The resulting by-products of the reaction are then desorbed from the surface and pumped out of the chamber, leaving behind the desired coating.

Understanding the Trade-offs and Advantages

Key Advantage: Low-Temperature Processing

The ability to deposit films at low temperatures is the defining benefit of PECVD. It opens the door to coating temperature-sensitive materials that are incompatible with other methods.

This includes everything from flexible plastics for displays to complex semiconductor devices that would be damaged by excessive heat.

Key Advantage: Film Quality and Control

Like traditional CVD, PECVD offers excellent control over the final film's properties. By carefully adjusting parameters like gas composition, pressure, and plasma power, engineers can fine-tune the film's thickness, chemical composition, density, and stress.

This results in high-purity, well-adhered coatings with excellent "wrap-around" properties, capable of uniformly covering complex, three-dimensional shapes.

Potential Drawback: Film Composition and Damage

The highly energetic plasma environment, while beneficial, can introduce complexities. Precursor gases often contain hydrogen (e.g., silane, ammonia), which can become incorporated into the growing film, potentially altering its optical or electronic properties.

Additionally, the bombardment of the surface by ions from the plasma can sometimes cause minor structural damage, which must be managed for highly sensitive applications.

Making the Right Choice for Your Goal

Selecting a deposition method requires a clear understanding of your material's limitations and your final objective.

- If your primary focus is coating heat-sensitive substrates like polymers or electronics: PECVD is the definitive choice, as it prevents thermal damage.

- If your primary focus is achieving the highest possible crystalline quality for a robust material: Traditional high-temperature CVD may be superior, provided your substrate can withstand the heat.

- If your primary focus is depositing a very simple film on a durable substrate: You might also consider Physical Vapor Deposition (PVD) techniques, which involve evaporation rather than a chemical reaction.

Understanding these fundamental differences empowers you to select the precise tool needed to achieve your material science objectives.

Summary Table:

| Feature | PECVD | Traditional CVD |

|---|---|---|

| Process Temperature | Low (250-350°C) | High (often >600°C) |

| Primary Energy Source | Plasma (RF/Microwave) | Thermal (Heat) |

| Ideal for Substrates | Heat-sensitive (plastics, electronics) | High-temperature tolerant (ceramics, metals) |

| Key Advantage | Prevents thermal damage, versatile applications | High crystalline quality films |

Ready to enhance your lab's capabilities with PECVD?

KINTEK specializes in providing advanced lab equipment, including PECVD systems, to help you deposit high-quality thin films on even the most delicate substrates. Our solutions are designed to meet the precise needs of modern laboratories, enabling breakthroughs in materials science and electronics.

Contact us today using the form below to discuss how our expertise can help you achieve your research and production goals. Let's find the perfect deposition solution for your application.

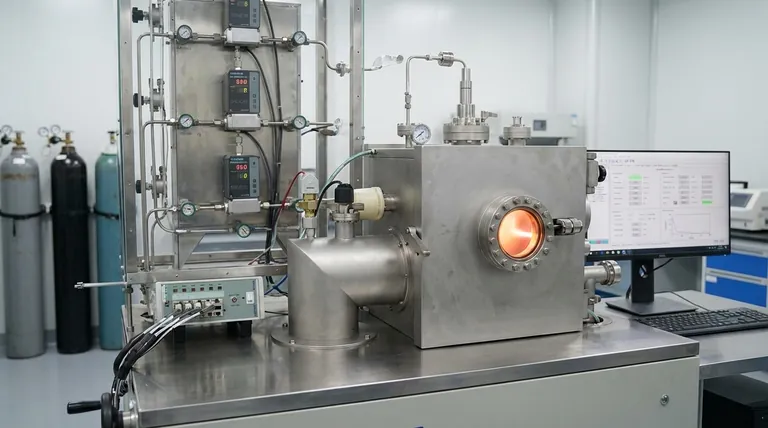

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is PECVD used for? Achieve Low-Temperature, High-Performance Thin Films

- What is plasma enhanced chemical vapor deposition? Achieve Low-Temperature, High-Quality Thin Films

- What is plasma in CVD process? Lowering Deposition Temperatures for Heat-Sensitive Materials

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method