At its core, sintering in electronics is a manufacturing process that uses heat and pressure to transform powdered materials into a solid, functional component without melting them. This method is crucial for creating many high-performance electronic parts, from ceramic capacitors to conductive interconnects, by bonding particles together at a microscopic level to achieve specific material properties.

Sintering is not just a way to form a shape; it is a materials science tool used to engineer the precise electrical, thermal, and mechanical characteristics required for modern electronic components, especially when working with materials that have very high melting points.

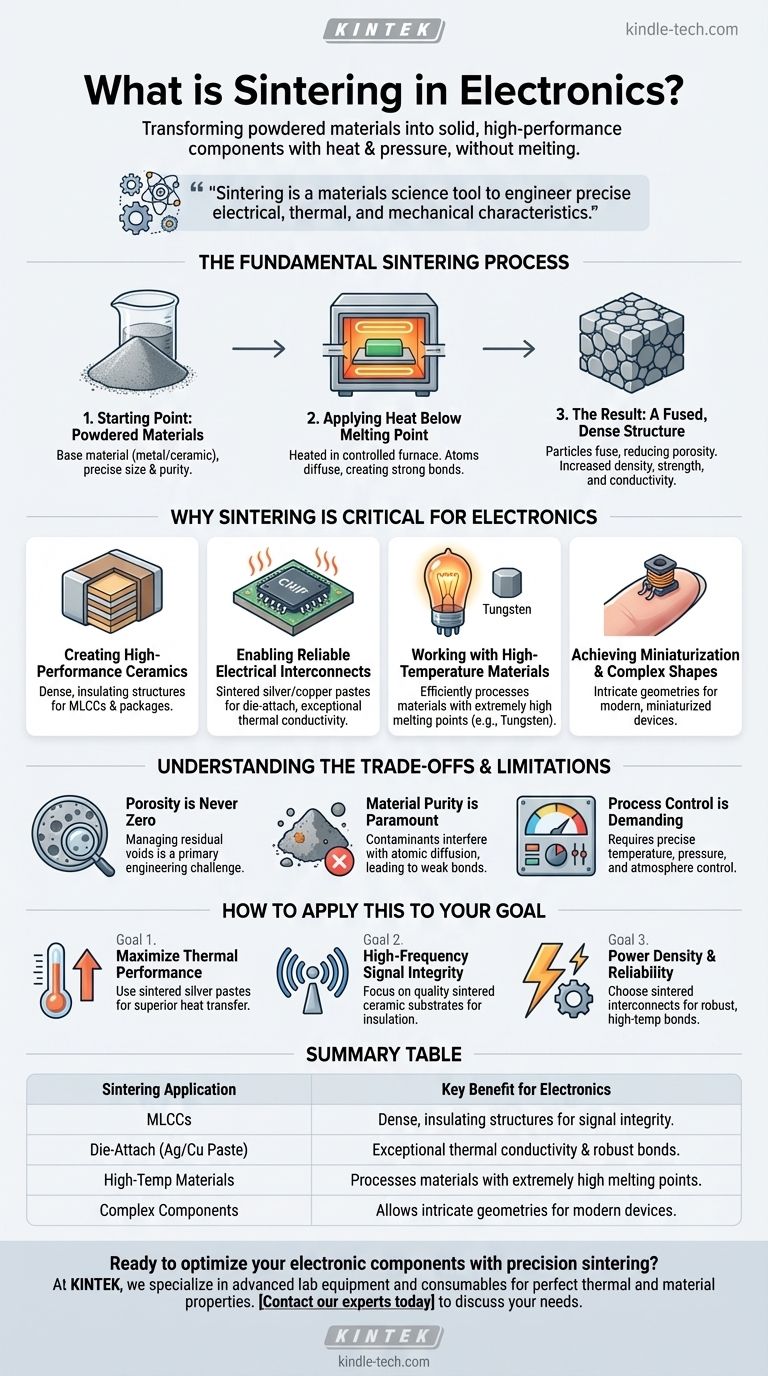

The Fundamental Sintering Process

Sintering is a thermal treatment that fundamentally changes the structure of a powdered material. It bridges the gap between a collection of loose particles and a durable, solid object with engineered properties.

The Starting Point: Powdered Materials

The process begins with a base material in powder form. This could be a metal like silver or copper for conductive applications, or a ceramic material for insulators and substrates. The precise size and purity of these particles are critical to the final component's performance.

Applying Heat Below the Melting Point

The powder, often pre-formed into a desired shape (called a 'green' part), is heated in a controlled furnace. Critically, the temperature is kept below the material's melting point. The applied thermal energy causes the atoms at the contact points of the powder particles to diffuse, creating strong metallurgical bonds.

The Result: A Fused, Dense Structure

As these bonds form, the particles fuse together, and the gaps between them shrink. This process reduces the porosity of the material, increasing its density, strength, and conductivity (both thermal and electrical). The final result is a solid component with properties tailored for its specific electronic function.

Why Sintering is Critical for Electronics

While the process is used in heavy industry, its application in electronics is one of precision. It enables the creation of components that would be difficult or impossible to manufacture using traditional melting and casting methods.

Creating High-Performance Ceramics

Many essential electronic components, such as multi-layer ceramic capacitors (MLCCs), insulators, and integrated circuit packages, are made from ceramic materials. Sintering is the primary method used to form these parts, creating the dense, insulating structures required for their function.

Enabling Reliable Electrical Interconnects

In power electronics and advanced microchips, components generate immense heat. Sintered silver or copper pastes are used as die-attach materials to bond a semiconductor die to its substrate. The resulting sintered layer provides exceptional thermal conductivity to dissipate heat and a robust mechanical bond that can withstand high temperatures.

Working with High-Temperature Materials

Sintering excels at processing materials with extremely high melting points, such as tungsten or molybdenum, which are used in applications like heat sinks and high-power vacuum tubes. Melting and casting these metals is energy-intensive and difficult, making sintering a more efficient and controllable alternative.

Achieving Miniaturization and Complex Shapes

The process allows for the creation of intricate and complex geometries that are essential for modern, miniaturized electronics. This is particularly valuable for manufacturing components like ferrite cores for inductors or custom-shaped substrates for RF and microwave circuits.

Understanding the Trade-offs and Limitations

While powerful, sintering is a demanding process with specific challenges that engineers must manage to ensure component reliability.

Porosity is Never Zero

Although sintering significantly densifies a material, it rarely eliminates all voids. Managing and minimizing this residual porosity is a primary engineering challenge, as excessive voids can degrade mechanical strength and thermal or electrical conductivity.

Material Purity is Paramount

The process is highly sensitive to impurities in the initial powder. Contaminants can interfere with the atomic diffusion process, leading to weak bonds and compromising the final component's performance and reliability.

Process Control is Demanding

Achieving consistent and repeatable results requires extremely precise control over temperature, pressure, and atmospheric conditions within the furnace. Small deviations can lead to significant variations in the final product's properties.

How to Apply This to Your Goal

Your specific interest in sintering depends on the performance characteristic you are trying to optimize in your electronic design.

- If your primary focus is maximum thermal performance: Look to sintered silver pastes for die-attach applications, as they offer superior heat transfer away from active components.

- If your primary focus is high-frequency signal integrity: Recognize that the quality of sintered ceramic substrates and packages directly impacts electrical insulation and signal loss.

- If your primary focus is power density and reliability: Understand that sintered interconnects provide the robust, high-temperature bonds necessary for modern power modules to function without failure.

Ultimately, understanding sintering reveals the hidden material science that underpins the performance and reliability of the most critical electronic devices.

Summary Table:

| Sintering Application | Key Benefit for Electronics |

|---|---|

| Multi-layer Ceramic Capacitors (MLCCs) | Creates dense, insulating structures for signal integrity |

| Die-Attach (Silver/Copper Paste) | Provides exceptional thermal conductivity and robust bonds |

| High-Temperature Materials (e.g., Tungsten) | Enables processing of materials with extremely high melting points |

| Complex & Miniaturized Components | Allows for intricate geometries essential for modern devices |

Ready to optimize your electronic components with precision sintering? At KINTEK, we specialize in the advanced lab equipment and consumables needed to achieve the perfect thermal and material properties for your high-performance electronics. Whether you're developing MLCCs, power modules, or RF circuits, our solutions support the demanding process control required for reliable results. Contact our experts today to discuss how we can help you enhance your product's reliability and performance.

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Spark Plasma Sintering Furnace SPS Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What are the factors influencing shrinkage during sintering? Control Dimensional Changes for Precision Parts

- Does sintering use diffusion? The Atomic Mechanism for Building Stronger Materials

- Why is a high vacuum required for sintering Ti-43Al-4Nb-1Mo-0.1B? Ensure Purity & Fracture Toughness

- Why must green bodies produced via binder jetting undergo treatment in a vacuum sintering furnace?

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost