In materials processing, sintering pressure is the external force applied per unit area to a mass of powder before or during heating. This pressure compacts the material, forcing individual particles into intimate contact, which facilitates the atomic bonding that fuses them into a solid object. It is a critical partner to heat in the sintering process, enabling the formation of a dense, solid part without melting the material.

Sintering pressure is not merely a force; it is a fundamental control parameter. How and when you apply this pressure directly dictates the final density, porosity, and mechanical integrity of the finished component by creating the ideal conditions for atomic diffusion to occur.

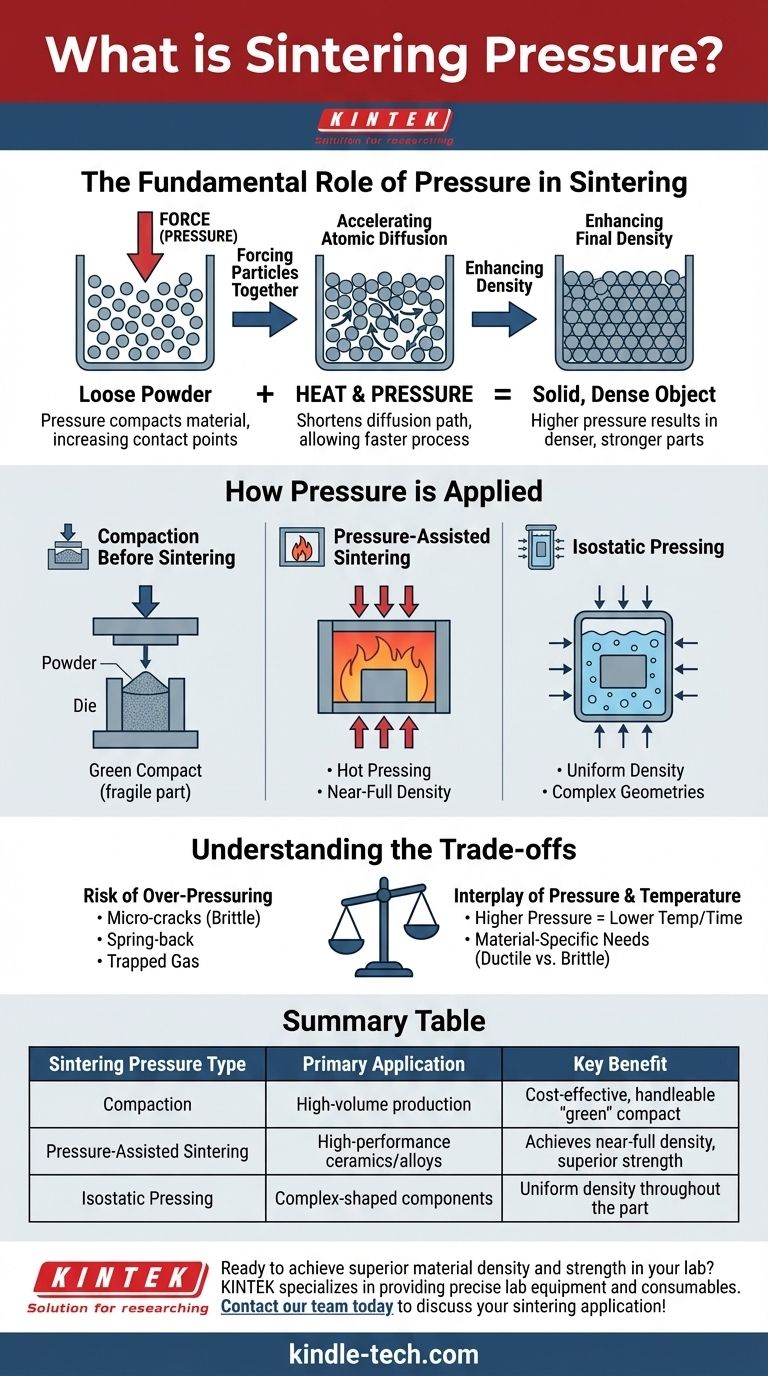

The Fundamental Role of Pressure in Sintering

Sintering transforms a loose powder into a solid object. While heat provides the energy for this transformation, pressure provides the necessary physical arrangement for it to happen efficiently.

Forcing Particles Together

The primary function of sintering pressure is to reduce the empty space, or porosity, within a powder mass. By applying force, particles are rearranged and deformed, dramatically increasing the number of contact points between them.

Accelerating Atomic Diffusion

Sintering occurs when atoms move across the boundaries of adjacent particles, creating strong metallic or ceramic bonds. This process, known as atomic diffusion, is driven by heat. However, its effectiveness depends on the distance atoms must travel.

By increasing the contact area between particles, pressure significantly shortens this diffusion path. This allows the sintering process to occur faster and at potentially lower temperatures.

Enhancing Final Density

The direct outcome of reducing porosity and promoting diffusion is an increase in the final part's density. Higher pressure generally results in a denser, stronger component with fewer internal voids, which are often sources of mechanical failure.

How Pressure is Applied in Sintering

The term "sintering pressure" can refer to force applied at different stages and in different ways, each suited to different goals.

Compaction Before Sintering

Most commonly, pressure is applied to the powder at room temperature before it enters the furnace. This initial step is often called compaction or pressing.

The goal is to form a "green compact"—a fragile part that has enough strength to be handled and moved to a sintering furnace, where it will be heated without any additional pressure.

Pressure-Assisted Sintering

In more advanced processes, pressure is applied simultaneously with heat inside a specialized furnace. This is known as pressure-assisted sintering or hot pressing.

This technique is highly effective at eliminating porosity and achieving near-full density. It is often used for high-performance ceramics and superalloys that are difficult to sinter using conventional methods.

Isostatic Pressing

For components with complex geometries, pressure can be applied uniformly from all directions using a fluid (a gas or liquid) as the pressure medium. This is called isostatic pressing.

This method ensures a much more uniform density throughout the part compared to pressing in a single direction, which can create density gradients.

Understanding the Trade-offs

Applying pressure is a balancing act. More is not always better, and the interaction with temperature and material type is critical.

The Risk of Over-Pressuring

Excessive pressure during initial compaction can introduce problems. It can cause micro-cracks in brittle particles (like ceramics) or lead to "spring-back," where the part expands and cracks after being ejected from the die. It can also trap atmospheric gases in closed-off pores, preventing full densification later.

The Interplay of Pressure and Temperature

Pressure and temperature are interconnected levers. For some materials, you can use higher pressure to achieve a target density at a lower temperature. This can save energy and prevent undesirable grain growth, which can weaken the material. Conversely, a lower pressure may require a higher temperature or longer sintering time.

Material-Specific Requirements

The ideal pressure depends heavily on the material. Ductile metal powders can withstand high compaction pressures, leading to very dense green compacts. Brittle ceramic powders, however, require a more controlled pressure application to avoid fracturing the individual particles.

Making the Right Choice for Your Goal

Selecting the right pressure strategy depends entirely on the desired outcome for your component.

- If your primary focus is maximum density and performance: Use a pressure-assisted method like hot pressing, which applies pressure during heating to create superior, near-void-free parts.

- If your primary focus is cost-effective, high-volume production: Employ conventional compaction before furnace sintering, carefully optimizing pressure to create a robust green compact without causing defects.

- If your primary focus is uniform properties in a complex shape: Consider isostatic pressing to ensure even compaction and minimize density variations throughout the component.

Ultimately, mastering sintering pressure transforms it from a simple force into a precise tool for engineering final material properties.

Summary Table:

| Sintering Pressure Type | Primary Application | Key Benefit |

|---|---|---|

| Compaction (Before Sintering) | High-volume production | Cost-effective, creates a handleable "green" compact |

| Pressure-Assisted Sintering | High-performance ceramics/alloys | Achieves near-full density, superior strength |

| Isostatic Pressing | Complex-shaped components | Uniform density throughout the part |

Ready to achieve superior material density and strength in your lab?

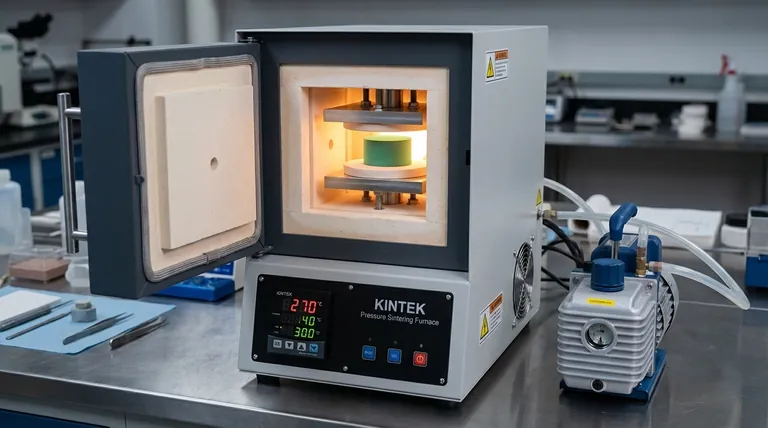

Sintering pressure is a critical parameter for success. The experts at KINTEK specialize in providing the precise lab equipment and consumables needed to master this process. Whether you are working with metals, ceramics, or advanced alloys, we can help you select the right pressing and sintering solutions to meet your specific goals for density, performance, and cost-efficiency.

Contact our team today to discuss your sintering application and optimize your results!

Visual Guide

Related Products

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Warm Isostatic Press for Solid State Battery Research

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

People Also Ask

- What is the function of a hydraulic heat press? Perfecting Solid-State Battery Polymer Membranes

- Why is precise pressure control via a hydraulic system necessary during hot pressing? Optimize Nanocopper Performance

- What role does a laboratory hydraulic hot press play in rice husk-based composite boards? Achieve Structural Density

- How does a laboratory hot press improve alloy performance? Optimize Liquid Phase Sintering for High-Strength Materials

- What is the function of a laboratory high-temperature hydraulic press? Optimize MEA Fabrication for HCl Electrolysis