The fundamental advantage of a hydraulic press is its ability to generate an immense amount of force from a very simple and compact design. This is achieved by applying Pascal's Law to multiply a small input force into a massive output, providing exceptional control over pressure and tonnage in a cost-effective and safe manner.

The core value of a hydraulic press isn't just its raw power; it's the unparalleled control and consistency it offers. This makes it the superior choice for any application where applying a specific, repeatable force is more critical than sheer operational speed.

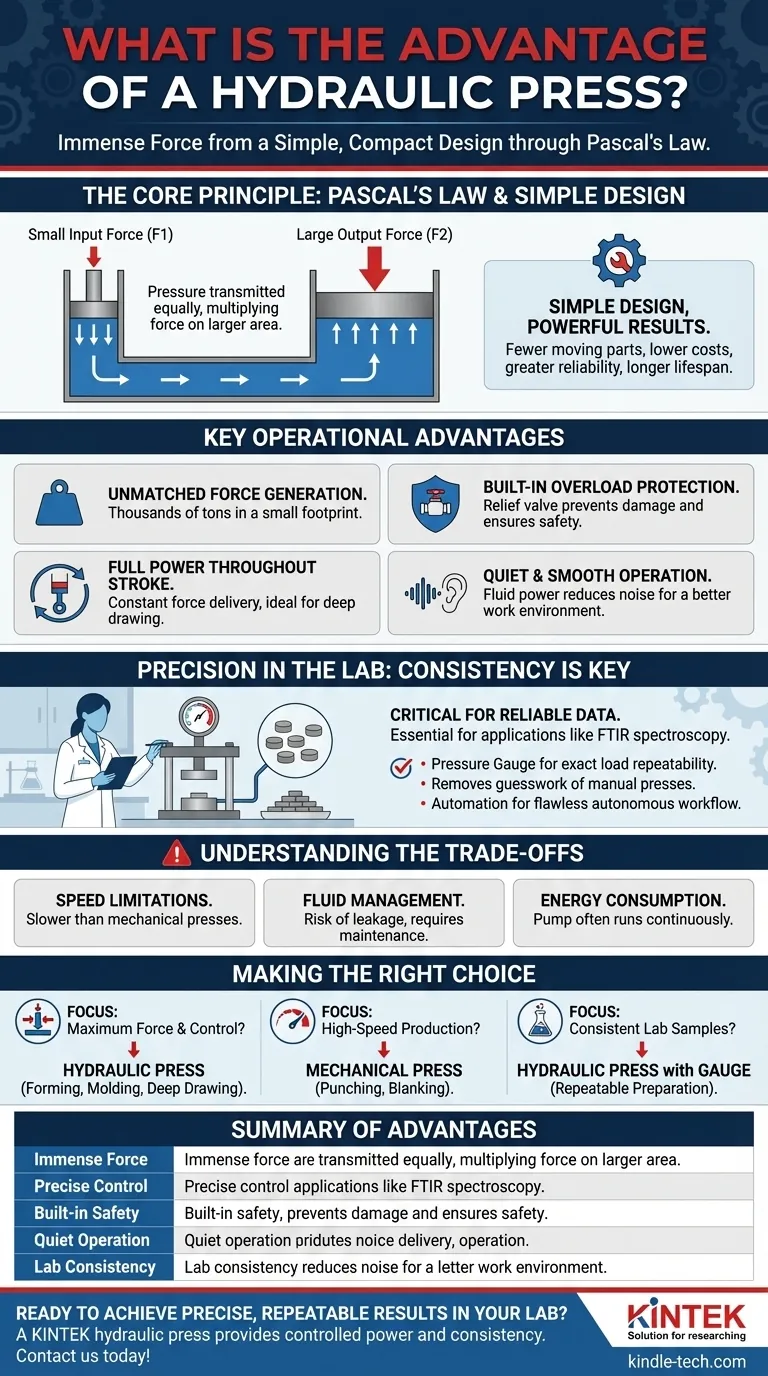

The Core Principle: How Force is Multiplied

The elegance of the hydraulic press comes from its straightforward application of a fundamental physics principle. This simplicity is the source of its most significant benefits.

Pascal's Law in Action

A hydraulic system works by using an incompressible fluid to transmit force. A small force applied to a piston in a small cylinder creates pressure in the fluid.

This pressure is transmitted equally throughout the fluid, acting on a much larger piston in a second cylinder. Because the second piston has a larger surface area, the transmitted pressure results in a massively multiplied output force.

Simple Design, Powerful Results

Unlike complex mechanical presses with gears, cranks, and flywheels, a hydraulic press has fewer moving parts. This simple design leads to lower initial and production costs.

Fewer components also mean greater reliability, less maintenance, and a longer operational lifespan for the machine and its tools.

Key Operational Advantages

The fluid-power principle translates directly into tangible benefits during operation, from safety to versatility.

Unmatched Force Generation

The primary reason to choose a hydraulic press is its capacity for high tonnage. It can generate thousands of tons of force within a relatively small physical footprint, something that is impractical for other press types.

Built-in Overload Protection

A hydraulic press has a built-in safety mechanism. The system's maximum pressure is set by a relief valve.

If the force required exceeds this limit, the valve opens, preventing the press from overloading. This protects the machine, the molds, and the operator without the risk of breaking components.

Full Power Throughout the Stroke

A critical advantage is the ability to deliver full, constant force at any point in the piston's stroke. Mechanical presses only deliver their maximum force at the very bottom of the stroke.

This makes hydraulic presses ideal for deep drawing, molding, or forming operations that require sustained pressure over a distance.

Quiet and Smooth Operation

Because they rely on the smooth flow of fluid rather than the impact of mechanical parts, hydraulic presses operate with significantly less noise. This creates a safer and more comfortable working environment.

Precision and Repeatability in the Lab

For scientific applications, the control offered by a hydraulic press is essential for producing reliable data. This is especially true for preparing samples for analysis like FTIR spectroscopy.

Why Consistency Matters

When preparing sample pellets, any variation in pressure can change the sample's density and thickness. This inconsistency leads to unreliable and non-repeatable test results.

The Role of the Pressure Gauge

Small lab-scale hydraulic presses include a pressure gauge. This allows a technician to apply the exact same load every time a sample is made.

This measured approach removes the guesswork inherent in manual "hand presses," ensuring every sample is uniform and every test is reliable.

Automation for Flawless Workflow

Automatic hydraulic presses take this a step further. Once programmed, they operate autonomously, producing perfectly consistent samples while freeing up technicians for other critical tasks.

Understanding the Trade-offs

No technology is perfect for every scenario. To make an informed decision, you must be aware of the limitations of a hydraulic press.

Speed Limitations

The main disadvantage is operational speed. Hydraulic presses are generally slower than their mechanical counterparts, making them less suitable for high-speed, high-volume applications like rapid stamping.

Fluid Management

The hydraulic fluid is the lifeblood of the system and requires management. There is a risk of fluid leakage, which can create safety and environmental concerns.

Regular maintenance is necessary to ensure fluid cleanliness and system integrity. Additionally, some hydraulic fluids can be flammable.

Energy Consumption

The hydraulic pump must often run continuously to maintain pressure, even when the press is not actively cycling. This can lead to higher energy consumption compared to mechanical presses that use the inertia of a flywheel.

Making the Right Choice for Your Application

Selecting the correct press depends entirely on the demands of your specific task.

- If your primary focus is maximum force and precise control: A hydraulic press is the ideal choice for forming, molding, and deep drawing applications where sustained pressure is key.

- If your primary focus is high-speed production: A mechanical press is better suited for rapid punching, blanking, or shallow stamping operations.

- If your primary focus is consistent lab sample preparation: A hydraulic press with a pressure gauge provides the essential repeatability that manual methods simply cannot match.

Ultimately, the hydraulic press excels where controlled power and adaptability, not just raw speed, are the critical factors for success.

Summary Table:

| Advantage | Description |

|---|---|

| Immense Force | Generates thousands of tons of force from a compact, simple design. |

| Precise Control | Delivers full, constant pressure throughout the stroke for consistent results. |

| Built-in Safety | Relief valve prevents overload, protecting the machine, tooling, and operator. |

| Quiet Operation | Smooth fluid power creates a safer, more comfortable working environment. |

| Lab Consistency | Essential for repeatable sample preparation (e.g., pellets for FTIR spectroscopy). |

Ready to achieve precise, repeatable results in your lab?

A hydraulic press from KINTEK provides the controlled power and consistency essential for reliable sample preparation and material testing. Our lab equipment is engineered for accuracy and durability, ensuring your workflows are both efficient and dependable.

Contact us today to discuss how a KINTEK hydraulic press can enhance your laboratory's capabilities and deliver the reliable data you need.

Get in touch with our experts now!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual Lab Heat Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis