The basic lining material for an induction furnace is a high-performance refractory, most commonly composed of magnesia, dolomite, or alumina. These specific materials are chosen because they possess extremely high melting points and can maintain their structural integrity and chemical stability at the intense temperatures required for melting metals.

The furnace lining is not merely a container; it is a critical safety and operational component. Its primary purpose is to safely contain the molten metal while simultaneously protecting the furnace's vital induction coil from thermal and electrical damage.

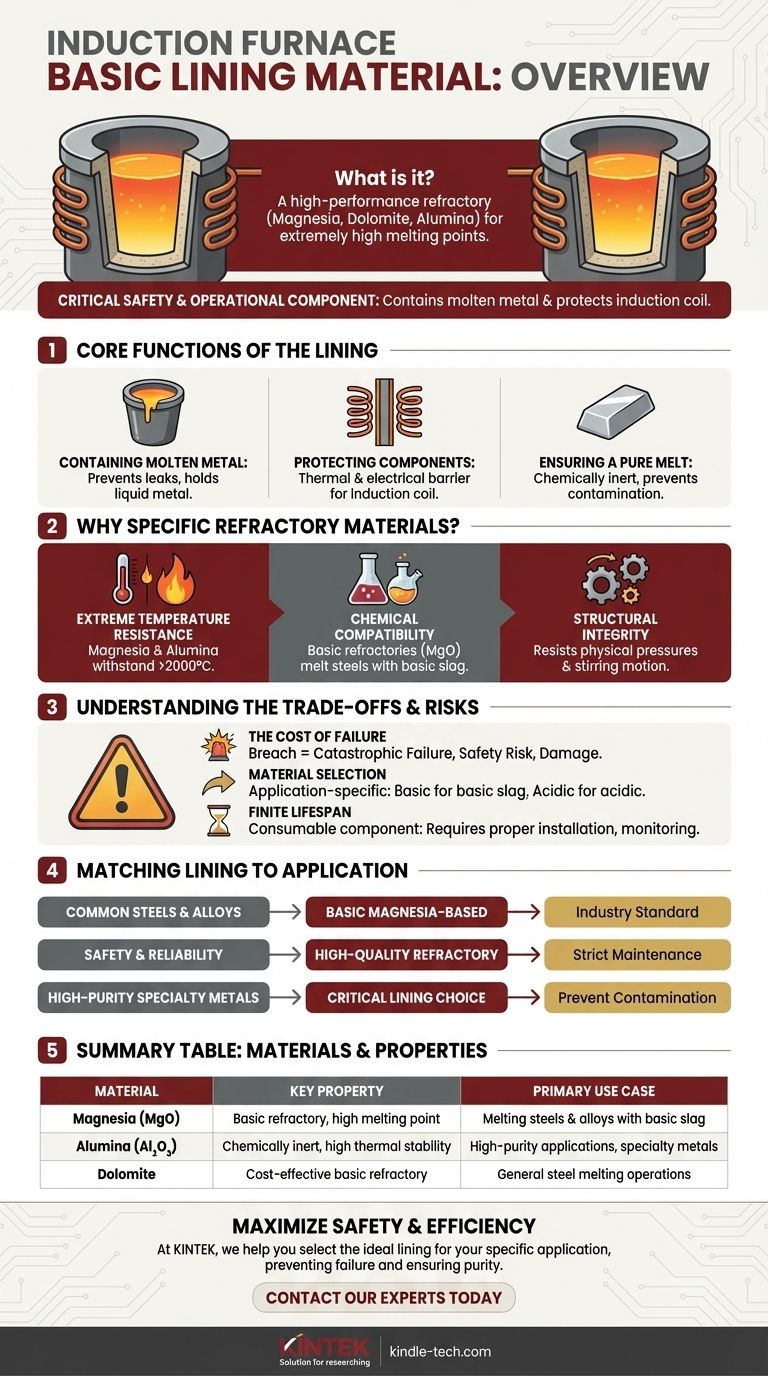

The Core Function of the Furnace Lining

To understand why specific materials are used, we must first appreciate the demanding role the lining plays. It is the most critical part of the induction furnace, serving multiple essential functions simultaneously.

Containing the Molten Metal

The most obvious function of the lining is to act as the crucible. It forms the vessel that holds the liquid metal, preventing it from leaking or breaking out.

Protecting Critical Components

The lining creates a thermal and electrical barrier between the superheated molten metal and the induction coil. A failure here would be catastrophic, destroying the coil and shutting down the furnace.

Ensuring a Pure Melt

The refractory material must be chemically inert with respect to the metal being melted. This ensures that the lining does not break down and contaminate the final alloy, which is crucial for high-purity applications.

Why Specific Refractory Materials Are Used

The term refractory simply means a material is resistant to decomposition by heat, pressure, or chemical attack. The choice of material is a deliberate engineering decision based on these properties.

Extreme Temperature Resistance

Materials like magnesia (MgO) and alumina (Al₂O₃) have melting points far exceeding those of the metals they are designed to contain. This thermal stability is the non-negotiable, primary requirement.

Chemical Compatibility

The "basic" in "basic lining" refers to its chemical nature. Basic refractories like magnesia are used to melt steels and other alloys that produce a basic slag, preventing a reactive breakdown of the lining itself.

Structural Integrity

The lining must be strong enough to withstand the physical pressures and stirring motion of the molten metal, which is agitated by the magnetic fields of the induction furnace.

Understanding the Trade-offs

While the concept seems straightforward, selecting and maintaining a lining involves critical considerations. An incorrect choice or poor maintenance leads directly to failure.

The Cost of Lining Failure

A breach in the lining is the single most dangerous failure mode for an induction furnace. It can lead to an explosion if molten metal comes into contact with the water-cooled induction coils, posing a severe safety risk and causing extensive equipment damage.

Material Selection is Not Universal

The choice of lining material is dictated by the application. While magnesia is a common basic lining, an acidic lining (like silica) would be used for melting metals that produce an acidic slag. Using the wrong type of lining will cause rapid chemical erosion and premature failure.

Finite Lifespan

No furnace lining lasts forever. It is a consumable component that slowly erodes with each melt cycle. Proper installation, sintering (the initial heating process), and ongoing monitoring are essential to maximize its life and operate safely.

Matching the Lining to the Application

The right material is always the one that provides the maximum safety and performance for the specific metal being processed.

- If your primary focus is melting common steels and alloys: A basic magnesia-based lining is the industry standard for its chemical compatibility and high performance.

- If your primary focus is safety and reliability: The selection of a high-quality refractory material and a strict maintenance schedule are the most important factors in preventing catastrophic failure.

- If your primary focus is producing high-purity specialty metals: The choice of lining is critical to prevent contamination and ensure the final product meets its required chemical specifications.

Ultimately, the induction furnace lining is the foundational element that makes safe, clean, and efficient melting possible.

Summary Table:

| Material | Key Property | Primary Use Case |

|---|---|---|

| Magnesia (MgO) | Basic refractory, high melting point | Melting steels and alloys with basic slag |

| Alumina (Al₂O₃) | Chemically inert, high thermal stability | High-purity applications, specialty metals |

| Dolomite | Cost-effective basic refractory | General steel melting operations |

Maximize the safety and efficiency of your melting operations with the right furnace lining.

At KINTEK, we understand that the furnace lining is the heart of your induction furnace. Choosing the correct refractory material is critical for preventing catastrophic failure, protecting your equipment, and ensuring the purity of your final product. Whether you are melting common steels or high-purity specialty metals, our experts can help you select the ideal lining solution for your specific application.

Let KINTEK provide the reliable lab equipment and consumables your laboratory needs. Contact our experts today for a consultation on optimizing your furnace performance and safety.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- What role does a quartz tube furnace play in hBN synthesis? Optimize Your Chemical Vapor Deposition Results

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing