In conclusion, a hydraulic press is a powerful and highly efficient industrial machine that uses a confined fluid to multiply force. Based on Pascal's law, it leverages a simple design to generate immense compressive force, making it a durable, adaptable, and preferred tool for a vast range of applications, from forging metal to molding advanced composites.

The fundamental value of a hydraulic press lies in its ability to act as a force multiplier. By applying a small amount of pressure to a small area, it generates an enormous force over a larger area, providing unmatched tonnage capacity with a simple and reliable mechanism.

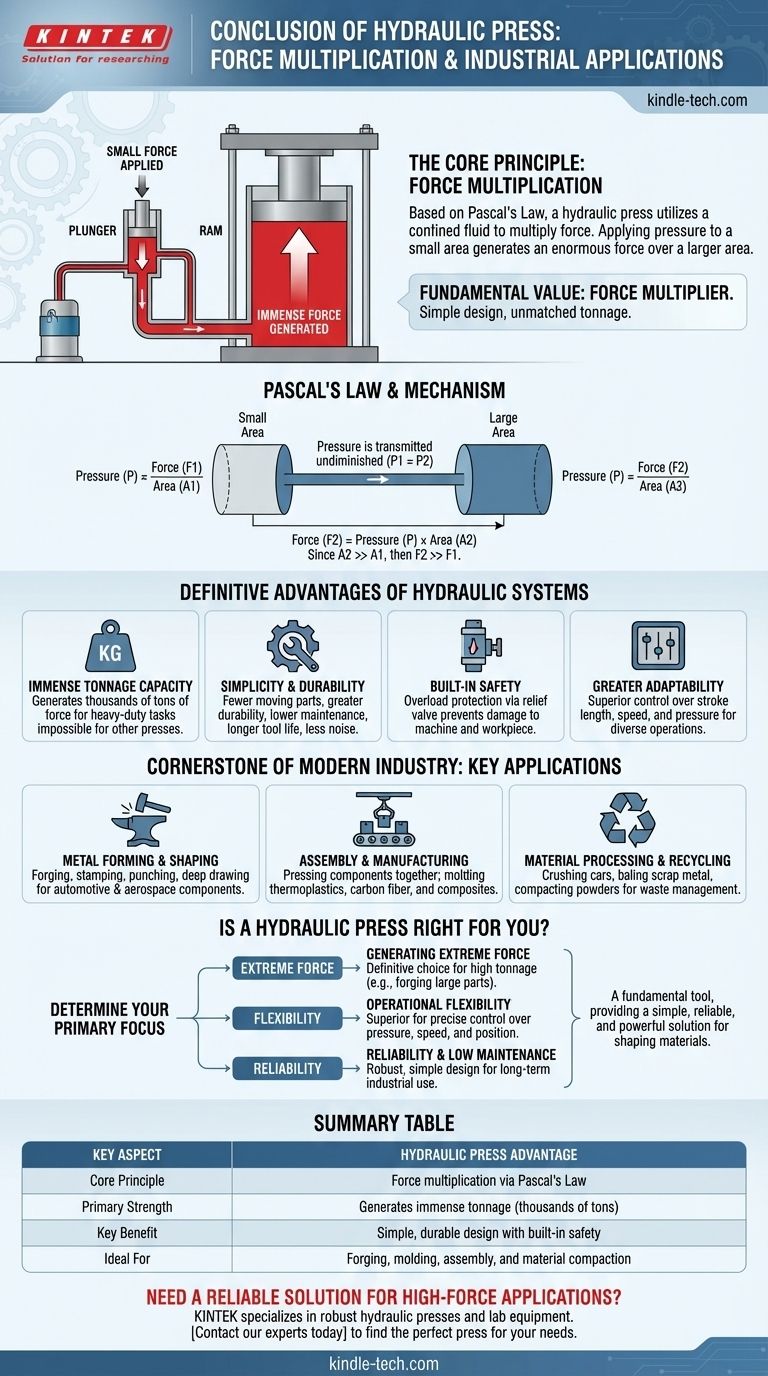

The Core Principle: Force Multiplication

A hydraulic press operates on a foundational concept in fluid mechanics. Understanding this principle is key to appreciating its power and widespread use.

Understanding Pascal's Law

The machine's operation is governed by Pascal's law. This principle states that pressure applied to an enclosed, incompressible fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In simple terms, pressure is distributed equally everywhere within the system.

The Key Components

A basic hydraulic press consists of two interconnected cylinders of different sizes, filled with hydraulic fluid. The smaller cylinder is known as the Plunger, and the larger one is the Ram.

How Force is Generated

When a small force is applied to the Plunger, it creates pressure in the hydraulic fluid. According to Pascal's law, this same pressure is exerted on the Ram.

Because the Ram has a much larger surface area, the same pressure results in a much larger output force. This is how the press multiplies the initial force to perform heavy-duty work like crushing, bending, and forming dense materials.

The Definitive Advantages of Hydraulic Systems

The preference for hydraulic presses over mechanical or pneumatic alternatives in many industries stems from a clear set of advantages rooted in their design.

Immense Tonnage Capacity

The primary advantage is the ability to generate immense pressure and force. A press can be designed to produce thousands of tons of force, allowing it to handle jobs that are impossible for other types of presses.

Simplicity and Durability

Hydraulic systems have fewer moving parts than complex mechanical presses. This simple design leads to greater durability, a longer lifespan for tools, lower maintenance requirements, and less operational noise.

Built-in Safety

A key feature is built-in overload protection. If the press exceeds its set pressure limit, a relief valve opens, preventing damage to the machine and the workpiece. This safety mechanism is inherent to the hydraulic circuit itself.

Greater Adaptability

Hydraulic presses offer superior control over stroke length, speed, and pressure. This makes them highly adaptable for a wide variety of operations, from deep drawing complex shapes to precise assembly tasks.

A Cornerstone of Modern Industry

The unique capabilities of hydraulic presses make them indispensable across a diverse range of sectors, from heavy manufacturing to advanced material science.

Metal Forming and Shaping

They are most commonly used for forging, stamping, punching, and deep drawing operations. The immense, controlled force is ideal for shaping thick sheets of metal into components for the automotive and aerospace industries.

Assembly and Manufacturing

Hydraulic presses are used for assembling components by pressing them together with great force. They are also critical for molding materials like thermoplastics, carbon fiber, and other composites.

Material Processing and Recycling

The raw power of a hydraulic press is used for tasks like crushing cars, baling scrap metal, and compacting various powders. This makes them a key tool in waste management and resource recycling.

How to Determine if a Hydraulic Press is Right for Your Application

Choosing the right machine depends entirely on the specific demands of your task. The strengths of a hydraulic press are clear and cater to distinct industrial needs.

- If your primary focus is generating extreme force: The hydraulic press is the definitive choice for applications requiring very high tonnage, such as forging large parts or crushing dense materials.

- If your primary focus is operational flexibility: A hydraulic press is superior when you need precise control over pressure, stroke speed, and position for complex forming or molding tasks.

- If your primary focus is reliability and low maintenance: The simple design with fewer moving parts makes it a robust and durable option for long-term industrial use.

Ultimately, the hydraulic press is a fundamental tool of modern industry because it provides a simple, reliable, and powerful solution to the challenge of shaping and forming materials.

Summary Table:

| Key Aspect | Hydraulic Press Advantage |

|---|---|

| Core Principle | Force multiplication via Pascal's Law |

| Primary Strength | Generates immense tonnage (thousands of tons) |

| Key Benefit | Simple, durable design with built-in safety |

| Ideal For | Forging, molding, assembly, and material compaction |

Need a reliable solution for high-force applications? KINTEK specializes in robust hydraulic presses and lab equipment, delivering the power and precision your laboratory or manufacturing process requires. Contact our experts today to find the perfect press for your needs—from metal forming to advanced composite molding.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual Lab Heat Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- Is a hydraulic forging press capable of exerting a maximum force? Understanding the Limits of Hydraulic Power

- Which press is suitable for heavy work? Choose the Right Press for Demanding Industrial Tasks

- What is the content of filter press solids? A Direct Reflection of Your Input Slurry

- What is the purpose of using a laboratory hydraulic press? Achieve Precision in Diamond-Aluminum Powder Processing

- What is the role of a laboratory hydraulic press in the preparation of polycrystalline ferroelectric ceramic materials?

- What is the thickness of XRF film? Ensure Accurate Coating and Sample Analysis

- What is the function of a bench-top laboratory hydraulic press for XRF? Maximize Accuracy in Prosopis juliflora Analysis

- What is a major cause of hydraulic system and component failures? Prevent Costly Downtime with Clean Fluid