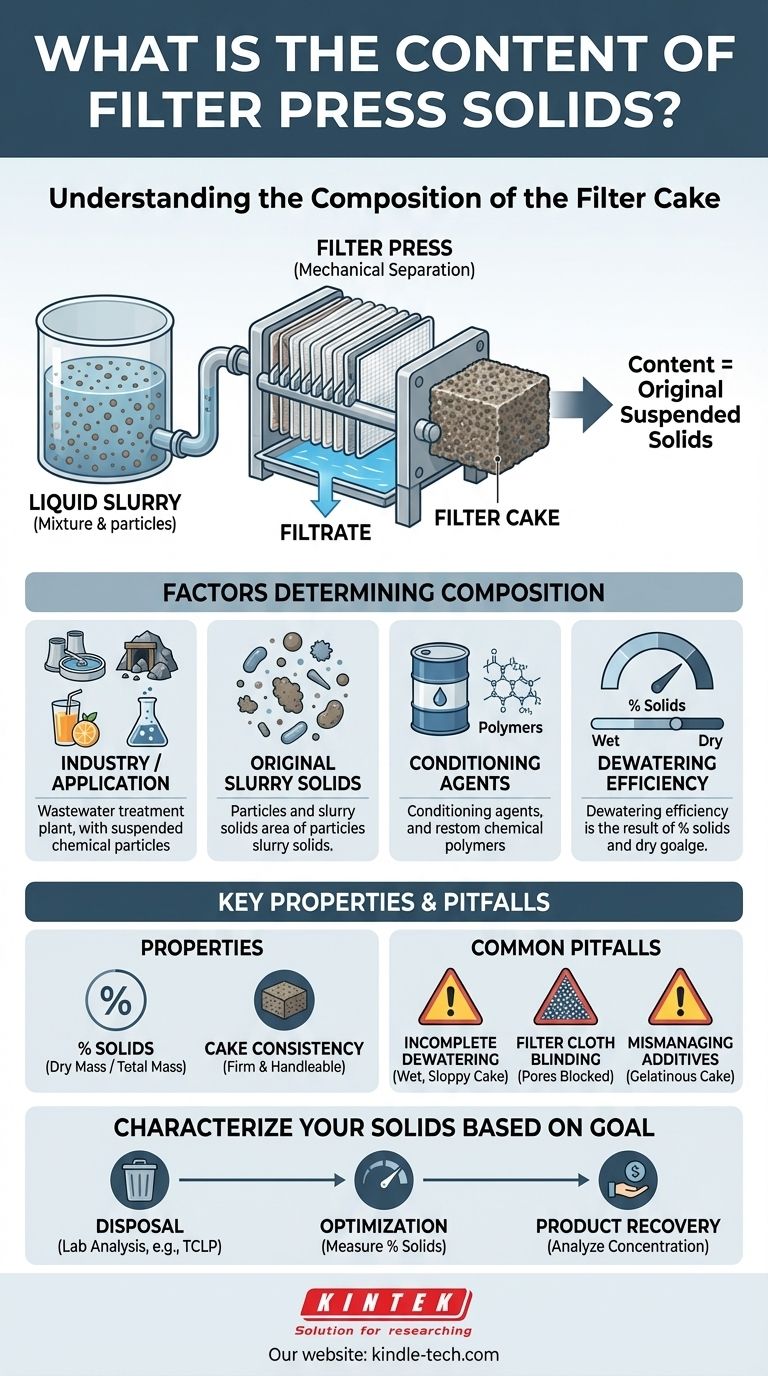

In short, the content of filter press solids is a compressed, dewatered material known as a "filter cake," which is composed entirely of the suspended solid particles from the initial liquid slurry that was fed into the press. The specific chemical and physical makeup of these solids depends completely on the industry and the particular process from which the slurry originated.

A filter press does not create or alter the fundamental nature of the solids; it is a mechanical separation device. Think of it as a powerful wringer: the solid material that comes out is the same solid material that went in, just with the vast majority of the liquid removed.

The Fundamental Principle: From Slurry to Cake

To understand the content of the solids, you must first understand the input. The entire process is about separating a mixture into its two constituent parts.

The Input: Liquid Slurry

A filter press begins its work with a slurry. This is simply a technical term for a mixture where solid particles are suspended, but not dissolved, in a liquid. This slurry is the source of everything that will eventually become the filter cake.

The Process: Mechanical Separation

The filter press pumps this slurry under high pressure into a series of chambers lined with filter cloths. The liquid, being able to pass through the fine pores of the cloth, exits the press as a clear liquid called filtrate.

The solid particles, being too large to pass through the filter cloth, are trapped and accumulate inside the chambers. As the process continues, these trapped solids are compressed, forcing out additional liquid.

The Output: Filter Cake

The final product is the filter cake—a dense, semi-dry slab of the compressed solids. The "content" of this cake is, therefore, identical to the content of the solids that were suspended in the original slurry.

What Determines the Solids' Composition?

The composition of the filter cake is defined by its source. The same machine can produce vastly different types of solids depending on the application.

Municipal & Industrial Wastewater

In wastewater treatment, the slurry often contains biological sludge from aeration basins or chemical precipitates. The resulting filter cake is typically composed of organic matter, microorganisms, and precipitated heavy metals (like metal hydroxides) that were removed from the water.

Mining & Mineral Processing

A mine might use a filter press to dewater tailings (waste rock powder) for safer storage or to concentrate valuable minerals. The filter cake here would consist of fine rock particles, clay, and the target minerals, such as concentrated gold, copper, or zinc.

Food & Beverage Production

In food processing, a filter press might clarify fruit juices or wine. The resulting cake would be made of pulp, yeast, and other organic solids. In edible oil refining, the cake consists of bleaching earth and other impurities removed from the oil.

Chemical Manufacturing

Chemical plants use filter presses to separate solid products from liquid reactants or solvents. The filter cake could be a valuable final product, such as a pigment, a precipitated catalyst, or a specific chemical compound.

Understanding Key Properties of the Solids

Beyond chemical composition, the physical properties of the cake are critical for handling and disposal.

Percent Solids (% Solids)

This is the most important measure of filter press performance. It represents the ratio of dry solid mass to the total mass of the cake. A cake with 80% solids is composed of 80% solid material and 20% residual moisture. A higher percent solids indicates better dewatering.

Cake Consistency

An optimized process produces a firm, solid cake that breaks apart cleanly when the press is opened. This makes it easy to collect, handle, and transport. A poor process results in a "sloppy" or wet cake that is difficult to manage.

The Impact of Conditioning Agents

Often, chemicals are added to the slurry before it enters the press to improve performance. These conditioning agents, such as polymers or lime, help particles clump together for easier separation. It is critical to remember that these additives become a part of the final filter cake and will affect its composition, weight, and disposal characteristics.

Common Pitfalls to Avoid

Achieving a good quality filter cake requires avoiding common operational issues.

Incomplete Dewatering

A wet, sloppy cake is the most frequent problem. This is often caused by insufficient cycle time, incorrect feed pressure, or using a filter cloth that is not appropriate for the specific particle size of the solids.

Filter Cloth Blinding

If the solid particles are extremely fine, they can become permanently lodged in the pores of the filter cloth, a phenomenon known as blinding. This restricts water flow, drastically reduces efficiency, and results in a wet, poorly formed cake.

Mismanaging Additives

Using too much or the wrong type of conditioning polymer can create a gelatinous cake that retains water and is difficult to handle. Furthermore, any additives must be accounted for during disposal analysis, as they are now part of the waste stream.

How to Characterize Your Solids

Your goal determines how you should approach analyzing your filter cake.

- If your primary focus is disposal or compliance: You must send a representative sample of the cake to a laboratory for chemical analysis (such as a Toxicity Characteristic Leaching Procedure or TCLP) to classify it for proper landfilling.

- If your primary focus is process optimization: Regularly measure the percent solids of your cake to gauge dewatering efficiency and make adjustments to pressure, cycle times, or chemical conditioning to maximize dryness.

- If your primary focus is product recovery: You must analyze the cake for the concentration of your target valuable material to calculate your process yield and ensure you are not losing product.

Ultimately, understanding that the filter cake is a direct reflection of your input slurry is the first step toward mastering your separation process.

Summary Table:

| Key Factor | Impact on Filter Cake Content |

|---|---|

| Industry/Application | Defines the fundamental chemical makeup (e.g., mining=minerals, wastewater=sludge). |

| Original Slurry Solids | The cake is composed of these exact particles, just dewatered. |

| Conditioning Agents | Additives like polymers become part of the final cake, affecting its properties. |

| Dewatering Efficiency | Measured by % Solids; higher % means a drier, more stable cake. |

Need to Optimize Your Filtration Process or Characterize Your Filter Cake?

Understanding the precise content and properties of your filter press solids is critical for efficient operation, cost-effective disposal, or maximizing product recovery. The experts at KINTEK specialize in lab equipment and consumables for analyzing and optimizing separation processes. We can help you select the right tools to measure percent solids, analyze cake composition, and improve your overall efficiency.

Let's discuss your specific slurry and filtration challenges. Contact our team today to find the perfect solution for your laboratory needs.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Double Plate Heating Press Mold for Lab

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- What is the purpose of specialized molding and pressure systems? Ensure Refractory Structural Homogeneity

- What are the components of a hydraulic press machine? A Guide to Core Parts & Functions

- How does a laboratory hydraulic press work with a PEEK mold? Master Sulfide Solid-State Battery Fabrication

- How does a laboratory hydraulic press contribute to the preparation of fly ash composite samples? Precision Pressing

- What is a major cause of hydraulic system and component failures? Prevent Costly Downtime with Clean Fluid

- What are the advantages of press moulding? Achieve Cost-Effective, High-Strength Parts

- What is the physical mechanism for sintering Cu-Cr-Nb powders? Overcoming Oxide Barriers with Hydraulic Loading

- How many tons can a hydraulic press produce? From 1 to 50,000+ Tons Explained