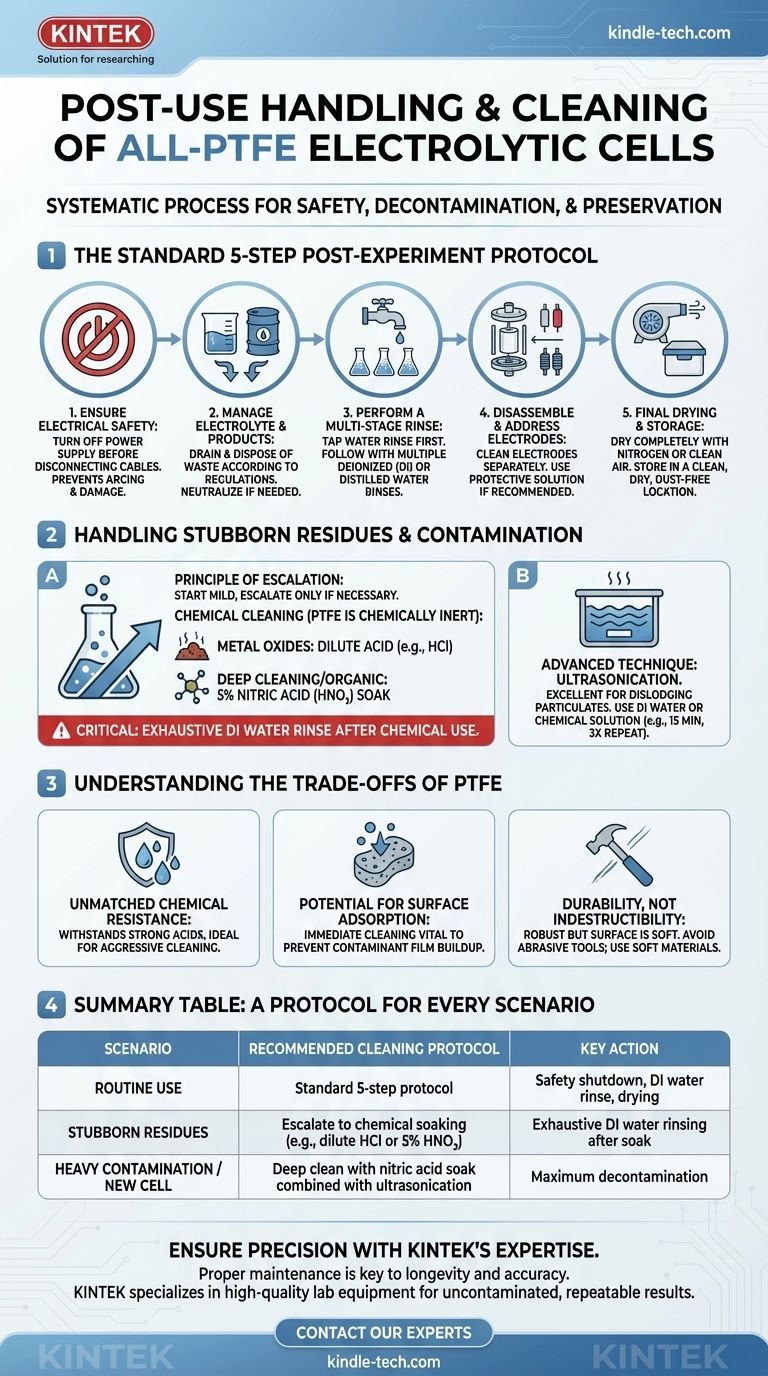

The correct post-use procedure for an all-PTFE electrolytic cell is a systematic process focused on safety, decontamination, and preservation. The essential steps involve safely powering down the system, properly disposing of waste electrolyte, rinsing the cell thoroughly with high-purity water, carefully cleaning the electrodes, and finally, drying and storing the components in a clean, dry environment to prevent contamination.

Your core objective is not merely to clean the cell, but to preserve its integrity for future experiments. Improper handling introduces contamination and degrades performance, compromising the reliability of your research. This procedure ensures your equipment remains a precise and dependable scientific instrument.

The Standard Post-Experiment Protocol

Following a consistent, step-by-step procedure after every experiment is the most effective way to maintain the performance and extend the life of your all-PTFE cell.

Step 1: Ensure Electrical Safety

Always turn off the power supply before disconnecting any cables from the electrolytic cell. This critical first step prevents electrical arcing, which can damage the equipment and pose a significant safety hazard.

Step 2: Manage Electrolyte and Products

Carefully drain the used electrolyte and any products from the cell. Waste liquid must be collected and disposed of according to your institution's environmental safety regulations. Never pour electrolytes down the drain without neutralization and verification.

Step 3: Perform a Multi-Stage Rinse

Begin by rinsing the cell components with tap water to remove the bulk of the residual electrolyte. Follow this with multiple, thorough rinses using deionized (DI) or distilled water. High-purity water is essential to remove any remaining ions and prevent the introduction of new contaminants.

Step 4: Disassemble and Address Electrodes

Carefully disassemble the cell. The electrodes require separate attention and should be cleaned according to their specific material and usage. For electrodes prone to oxidation, consider storing them in a protective solution as recommended by the manufacturer.

Step 5: Final Drying and Storage

Dry the PTFE cell body and all components completely. A stream of dry nitrogen or clean, compressed air is ideal for this. Alternatively, allow the parts to air dry thoroughly. Store the disassembled cell in a dry, dust-free location to await its next use.

Handling Stubborn Residues and Contamination

Over time, or after specific experiments, simple rinsing may not be sufficient. In these cases, a more intensive cleaning protocol is required.

The Principle of Escalation

Always start with the mildest cleaning method possible and only escalate if necessary. This minimizes the risk of inadvertently damaging the cell's surfaces.

Chemical Cleaning

PTFE is renowned for its extreme chemical inertness, allowing for aggressive cleaning methods that would destroy other materials.

- For Metal Oxides: Stubborn deposits like rust can often be removed with a dilute acid, such as hydrochloric acid (HCl).

- For General Deep Cleaning: For a new cell or one with heavy organic contamination, soaking the body in 5% nitric acid (HNO₃) for several hours is a highly effective procedure.

When using any chemical agent, always control the concentration and duration. Afterward, a critical, exhaustive rinse with large amounts of deionized water is mandatory to remove all traces of the cleaning chemical.

Advanced Technique: Ultrasonication

Using an ultrasonic bath is an excellent way to dislodge stubborn particulate matter from the cell surfaces. This can be done with deionized water or in conjunction with a chemical cleaning solution (like nitric acid) for maximum effect. A common protocol is to sonicate for 15 minutes, repeated three times with fresh DI water each time.

Understanding the Trade-offs of PTFE

The material properties of PTFE directly influence the cleaning protocol. Understanding them is key to proper maintenance.

Benefit: Unmatched Chemical Resistance

The primary advantage of an all-PTFE cell is its ability to withstand nearly all corrosive chemicals. This allows for the use of strong acids for cleaning, a method that is not viable for glass or standard polymer cells.

Pitfall: Potential for Surface Adsorption

While chemically inert, PTFE surfaces can sometimes adsorb organic molecules. This makes immediate cleaning after use especially important to prevent the buildup of a persistent, contaminating film that can be difficult to remove later.

Reality: Durability, Not Indestructibility

Unlike fragile glass cells, PTFE is a robust and durable material that resists breakage from physical shock. However, its surface is relatively soft and can be scratched by abrasive tools or powders. Always use soft, non-abrasive tools for any mechanical cleaning.

A Protocol for Every Scenario

Your cleaning strategy should adapt to the specific situation to ensure both efficiency and effectiveness.

- For routine, daily experiments: Follow the standard 5-step protocol of safe shutdown, waste removal, DI water rinsing, electrode care, and proper drying.

- When facing visible residues or suspected contamination: Escalate your cleaning by first trying chemical soaking with a suitable acid, followed by a thorough DI water rinse.

- For commissioning a new cell or after long-term storage: Perform a full deep clean using a nitric acid soak combined with ultrasonication to ensure a pristine, contaminant-free surface.

By consistently applying the correct maintenance procedure, you ensure your equipment remains an asset, not a variable, in your research.

Summary Table:

| Scenario | Recommended Cleaning Protocol |

|---|---|

| Routine Use | Standard 5-step protocol: Safety shutdown, waste disposal, DI water rinse, electrode care, drying. |

| Stubborn Residues | Escalate to chemical soaking (e.g., dilute HCl or 5% HNO₃) followed by exhaustive DI water rinsing. |

| Heavy Contamination / New Cell | Deep clean with nitric acid soak combined with ultrasonication for maximum decontamination. |

Ensure your lab's precision with KINTEK's expertise. Proper maintenance is key to the longevity and accuracy of your PTFE electrolytic cells. KINTEK specializes in high-quality lab equipment and consumables, providing the reliable instruments and support your laboratory needs for uncontaminated, repeatable results. Contact our experts today via our contact form to discuss your specific requirements and how we can help optimize your processes.

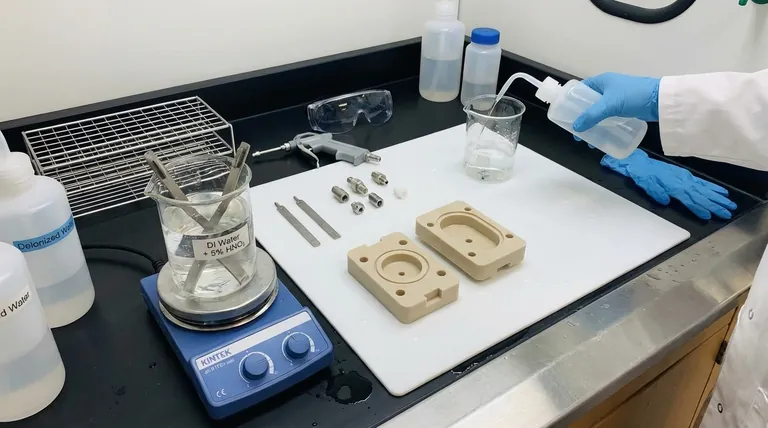

Visual Guide

Related Products

- Electrolytic Electrochemical Cell Gas Diffusion Liquid Flow Reaction Cell

- Custom PTFE Teflon Parts Manufacturer for Non-Standard Insulator Customization

- Custom PTFE Teflon Parts Manufacturer for PTFE Measuring Cylinder 10/50/100ml

- Platinum Auxiliary Electrode for Laboratory Use

- Li-Air Battery Case for Battery Lab Applications

People Also Ask

- What precautions should be taken regarding temperature when using an all-PTFE electrolytic cell? Ensure Safe & Accurate Experiments

- What is the purpose of the double-layer structure in the H-type electrolytic cell? Achieve Precise Thermal Control

- What functions do electrolytic cells perform in PEC water splitting? Optimize Your Photoelectrochemical Research

- What are the advantages of using a PTFE deposition tank for EPD? Achieve Unmatched Coating Precision on Stainless Steel

- What advantages do flow electrolytic cells offer over H-type cells? Optimize CO2 Electrolysis Efficiency