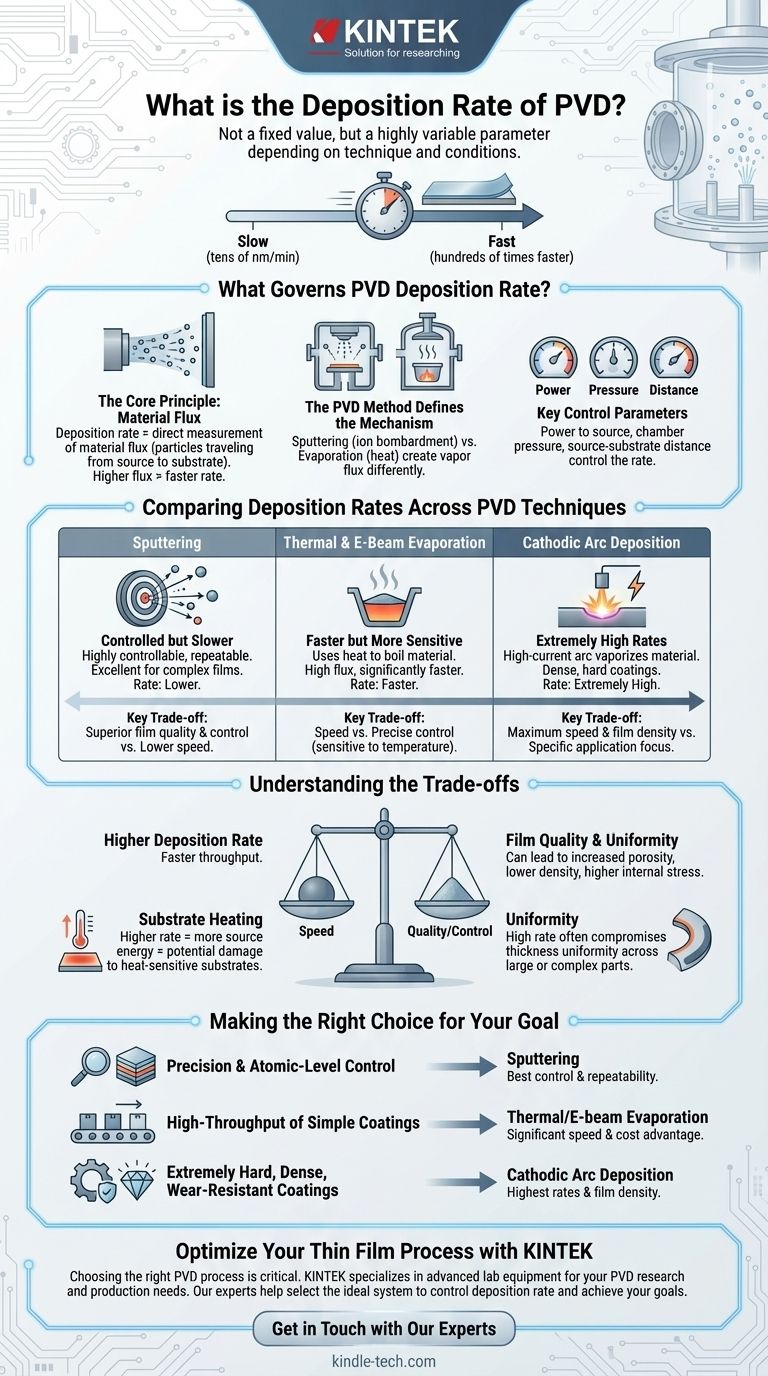

The deposition rate of Physical Vapor Deposition (PVD) is not a single value but a highly variable parameter that depends entirely on the specific PVD technique being used and the process conditions. While a simple thermal evaporation process might deposit material at tens of nanometers per minute, a high-power cathodic arc process can achieve rates hundreds of times faster. The rate is a critical, controllable output of the process, not a fixed property of PVD itself.

The central challenge is not finding a single deposition rate for PVD, but understanding how each specific PVD method (like sputtering or evaporation) generates material vapor. This mechanism dictates the achievable deposition rate and the fundamental trade-off between production speed and the final quality of the thin film.

What Governs PVD Deposition Rate?

The speed at which a thin film grows is determined by the rate at which atoms or molecules arrive at the substrate surface. This is a function of the PVD method, the material being deposited, and the specific parameters of the vacuum chamber environment.

The Core Principle: Material Flux

Deposition rate is a direct measurement of material flux—the number of vaporized particles from the source material (the "target") that successfully travel through the vacuum and condense onto your part (the "substrate").

A higher flux means a faster deposition rate. The goal of any PVD process is to generate and control this flux with precision.

The PVD Method Defines the Mechanism

Different PVD techniques create this vapor flux in fundamentally different ways, which is the primary reason for their varying deposition rates.

The most common methods include sputtering, where ions bombard a target to eject atoms, and evaporation (thermal or e-beam), where heat is used to boil material into a vapor. Each has its own distinct rate characteristics.

Key Control Parameters

Beyond the choice of method, operators control the rate using several key parameters. The most common are the power applied to the source, the vacuum chamber pressure, and the distance between the source and the substrate.

Comparing Deposition Rates Across PVD Techniques

While exact numbers depend on the specific material and system geometry, we can compare the general rate capabilities of the major PVD technologies.

Sputter Deposition: Controlled but Slower

Sputtering is a momentum-transfer process. It is highly controllable and repeatable, making it ideal for complex, high-quality optical and electronic films.

However, the process of ejecting individual atoms via ion bombardment is inherently less efficient than bulk evaporation. This generally results in lower deposition rates compared to evaporation techniques.

Thermal & E-Beam Evaporation: Faster but More Sensitive

Evaporation uses heat to turn a source material into a vapor. This process can generate a very high flux of material, leading to significantly faster deposition rates than sputtering, especially with electron-beam (e-beam) evaporation which can intensely focus energy.

The trade-off is control. The rate is extremely sensitive to temperature, making precise, stable control more challenging.

Cathodic Arc Deposition: Extremely High Rates

This method uses a high-current electric arc to vaporize the source material, creating a dense, highly ionized plasma.

This results in extremely high deposition rates and produces very dense, hard coatings. It is the preferred method for many wear-resistant tool coatings where speed and film density are paramount.

Understanding the Trade-offs

Selecting a PVD process is never just about maximizing speed. A higher deposition rate often comes with significant compromises that must be carefully considered.

Speed vs. Film Quality

Depositing atoms too quickly can prevent them from settling into an ideal, dense film structure. This can lead to increased porosity, lower density, and higher internal stress in the coating, potentially compromising its performance.

Rate vs. Substrate Heating

Higher deposition rates require more energy at the source, which in turn radiates more heat toward the substrate. This can damage heat-sensitive substrates like plastics or certain electronic components.

Rate vs. Uniformity

Achieving a high deposition rate while maintaining excellent film thickness uniformity across a large or complex-shaped part is a major challenge. Often, the system geometry must be optimized for one at the expense of the other.

Making the Right Choice for Your Goal

The optimal deposition rate is determined by the application's requirements for quality, throughput, and cost.

- If your primary focus is precision and atomic-level control for complex multilayer films: Sputtering offers the best control and repeatability, even at its characteristically lower rates.

- If your primary focus is high-throughput deposition of simple metals or optical coatings: Thermal or E-beam evaporation provides a significant speed and cost advantage.

- If your primary focus is creating extremely hard, dense, wear-resistant coatings: Cathodic arc deposition delivers the highest rates and film density required for demanding applications.

Ultimately, mastering a PVD process means understanding and controlling the deposition rate to achieve the desired balance between manufacturing speed and the final performance of the coating.

Summary Table:

| PVD Method | Typical Rate Characteristic | Key Trade-off |

|---|---|---|

| Sputtering | Lower, Highly Controlled | Superior film quality & control |

| Evaporation (Thermal/E-beam) | Faster | Speed vs. precise control |

| Cathodic Arc | Extremely High | Maximum speed & film density |

Optimize Your Thin Film Process with KINTEK

Choosing the right PVD process and deposition rate is critical to achieving the perfect balance of coating speed, quality, and cost for your specific application. Whether you need the precise control of sputtering for electronic films, the high throughput of evaporation for optical coatings, or the extreme durability of cathodic arc deposits, the right equipment is key.

KINTEK specializes in advanced lab equipment and consumables for all your PVD and thin film research and production needs. Our experts can help you select the ideal system to control deposition rate and achieve your performance goals.

Contact us today to discuss your project and discover how KINTEK solutions can enhance your laboratory's capabilities.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process