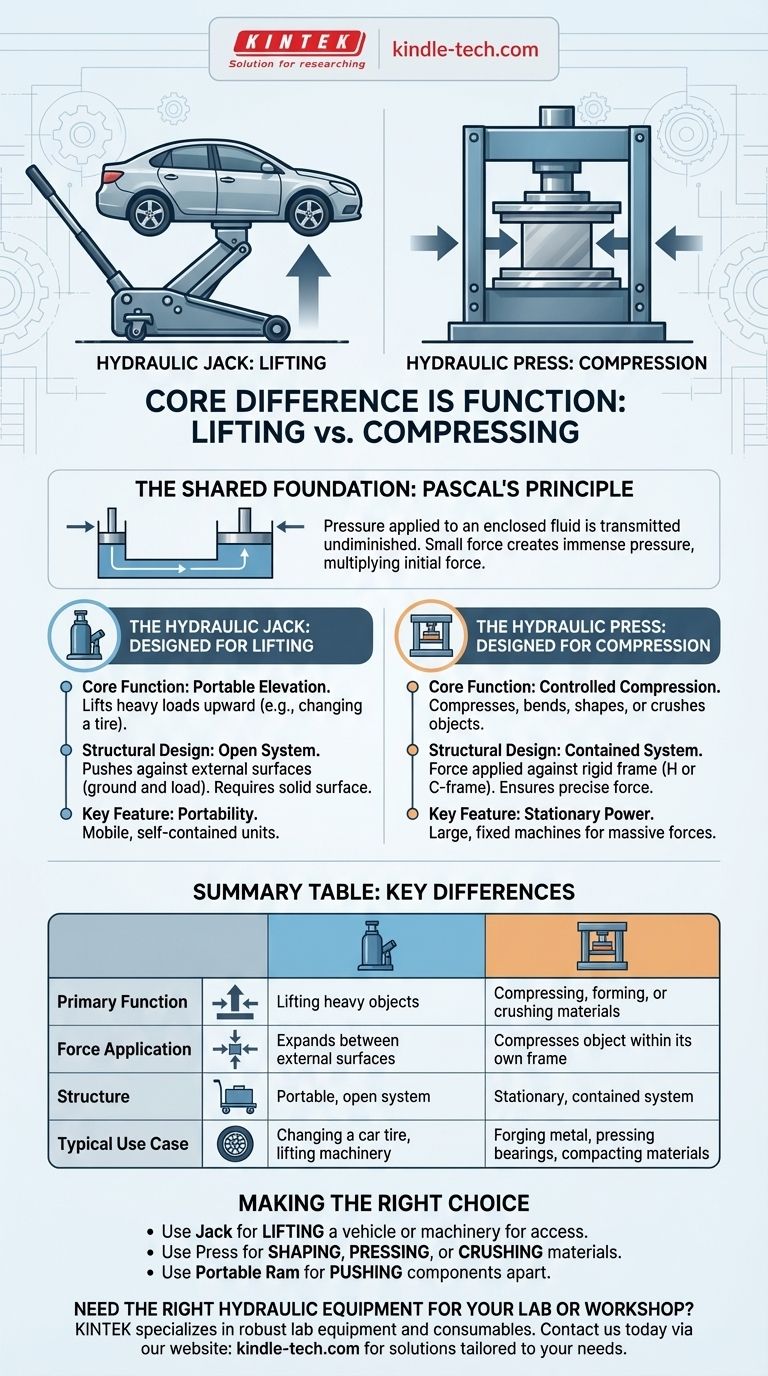

At its core, the difference is function. A hydraulic jack is a portable tool designed specifically for lifting heavy objects, like a car. In contrast, a hydraulic press is a stationary machine designed for compressing, crushing, or forming materials within a rigid frame. Both use the same hydraulic principle, but their mechanical structure and intended application are fundamentally distinct.

While both tools multiply force using fluid pressure, their design dictates their purpose. A jack is built to push one thing away from another (lifting), while a press is built to squeeze something between two of its own components (compressing).

The Shared Foundation: Pascal's Principle

What is Pascal's Principle?

Both the hydraulic jack and the press operate on a law of physics known as Pascal's principle.

This principle states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

How It Creates Force

In simple terms, applying a small amount of force to a small piston creates immense pressure in the hydraulic fluid. This pressure then acts on a much larger piston, multiplying the initial force significantly and allowing you to lift or crush objects that would otherwise be impossible to move.

The Hydraulic Jack: Designed for Lifting

Core Function: Portable Elevation

The primary and sole purpose of a hydraulic jack is to lift heavy loads. Its design is optimized for pushing a load upward, creating space for maintenance or movement.

Think of changing a tire on a car; the jack is the tool that elevates the vehicle off the ground.

Structural Design: An Open System

A jack's structure is designed to push against two external surfaces: the ground (or a stable base) and the load it is lifting.

It doesn't contain the force within its own structure. Instead, it acts as a powerful, expanding link between the ground and the object. This is why it must be placed on a solid, level surface to operate safely.

Key Feature: Portability

Most hydraulic jacks, especially bottle jacks and floor jacks, are designed to be portable. They are self-contained units that can be easily moved to wherever the work needs to be done.

The Hydraulic Press: Designed for Compression

Core Function: Controlled Compression

A hydraulic press is engineered to apply a controlled, massive force to an object to compress, bend, shape, or crush it.

Common applications include pressing bearings into a housing, forging metal parts, or compacting materials for disposal.

Structural Design: A Contained System

This is the most critical difference. A hydraulic press is built with an extremely strong, rigid frame, often in an "H" or "C" shape.

The hydraulic cylinder pushes a ram or platen downwards against a fixed worktable or bed. The immense force is entirely contained and opposed by the machine's own frame, ensuring precise and safe compression.

Key Feature: Stationary Power

Due to their size and the massive forces they handle, hydraulic presses are almost always large, stationary machines. The workpiece is brought to the press, not the other way around.

Understanding the Key Differences

Application: Lifting vs. Compressing

This is the most obvious distinction. If you need to raise an object, you need a jack. If you need to squeeze, flatten, or form an object, you need a press. Using one for the other's job is both ineffective and highly dangerous.

Structure: Open vs. Contained Force

A jack applies an expanding force between two separate objects. A press applies a compressive force to an object held within its own frame. This structural difference is the primary reason their functions are not interchangeable.

Portability: Mobile vs. Stationary

Jacks are designed for mobility and use in various locations. Presses are fixed installations within a workshop or factory, providing a stable platform for controlled force application.

Making the Right Choice for Your Task

Choosing between these tools is determined entirely by the job you need to accomplish.

- If your primary focus is lifting a vehicle or heavy machinery for access: A hydraulic jack is the only appropriate tool for the task.

- If your primary focus is shaping metal, pressing bearings, or crushing materials: A hydraulic press provides the necessary force containment and control.

- If your primary focus is pushing components apart (e.g., in bodywork): A portable hydraulic ram kit (often called a "Porta-Power") may be used, which acts like a jack but is designed for spreading force.

Understanding this fundamental distinction between lifting and compressing ensures you apply force safely and effectively, using the right tool for the right job.

Summary Table:

| Feature | Hydraulic Jack | Hydraulic Press |

|---|---|---|

| Primary Function | Lifting heavy objects | Compressing, forming, or crushing materials |

| Force Application | Expands between two external surfaces (e.g., ground and load) | Compresses an object within its own rigid frame |

| Structure | Portable, open system | Stationary, contained system (H or C-frame) |

| Typical Use Case | Changing a car tire, lifting machinery | Forging metal, pressing bearings, compacting materials |

Need the Right Hydraulic Equipment for Your Lab or Workshop?

Understanding the difference between a jack and a press is the first step to safe and efficient operations. At KINTEK, we specialize in providing robust lab equipment and consumables tailored to your specific needs. Whether you require precise compression for material testing or reliable lifting solutions, our expertise ensures you get the right tool for the job.

Contact us today via our [#ContactForm] to discuss how KINTEK's hydraulic solutions can enhance your productivity and safety.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy