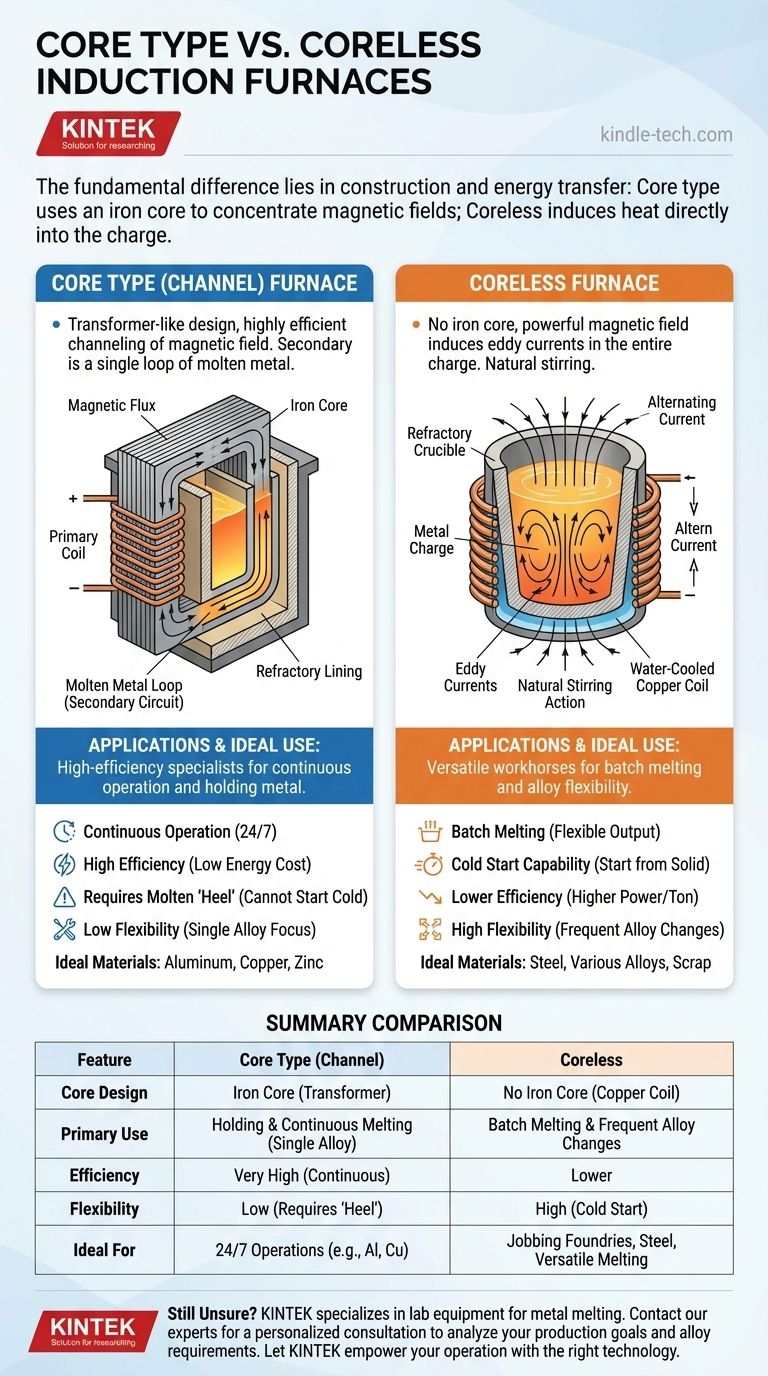

The fundamental difference between a core type and a coreless induction furnace lies in their construction and how they transfer energy. A core type furnace, more commonly known as a channel furnace, uses an iron core to concentrate a magnetic field into a small loop of molten metal. In contrast, a coreless furnace induces heat directly into the entire metallic charge contained within a crucible, operating without a central iron core. This structural distinction is the primary driver behind their vastly different operational capabilities and applications.

The decision between a core type (channel) and a coreless furnace is not about which is superior, but which is fit for purpose. Channel furnaces are high-efficiency specialists for continuous operation and holding metal, while coreless furnaces are versatile workhorses for batch melting and alloy flexibility.

Deconstructing the Designs: Core vs. Coreless

To understand which furnace to use, you must first understand how they are built and why that matters. The names "core type" and "coreless" refer directly to the presence or absence of a laminated iron core, which is the heart of the design difference.

The Core Type (Channel) Furnace

A core type, or channel furnace, operates exactly like a transformer. It has a primary coil wrapped around an iron core, which efficiently channels the magnetic field.

The unique feature is its secondary "winding." Instead of another coil of wire, the secondary is a single, continuous loop of the molten metal itself, which flows through a channel in the refractory material.

This design is extremely efficient because the iron core ensures a very tight magnetic coupling between the primary coil and the molten metal loop.

The Coreless Furnace

A coreless furnace functions without any iron core to direct the magnetic field. Instead, it consists of a crucible made of refractory material that holds the metal charge.

This crucible is surrounded by a water-cooled copper coil. When alternating current flows through this coil, it generates a powerful magnetic field that passes directly through the metal inside.

This field induces strong eddy currents within the entire charge, causing it to heat up and melt rapidly from the inside out. The interaction of the currents also creates a natural stirring action, which promotes a uniform temperature and chemical composition.

How Design Dictates Application

The structural differences directly translate into distinct advantages and ideal use cases. One is built for steady, continuous work, while the other excels at flexible, intermittent tasks.

Channel Furnaces: The High-Efficiency Holder

Because of their highly efficient transformer design, channel furnaces are ideal for holding very large volumes of molten metal at a specific temperature for extended periods.

They are also used for continuous or long-run melting campaigns, particularly with lower-melting-point, non-ferrous metals like aluminum, copper, and zinc. Their efficiency translates to lower energy costs in 24/7 operations.

Coreless Furnaces: The Versatile Melter

The coreless furnace's greatest strength is its flexibility. It can be started from a cold, solid charge and can melt a vast range of metals, from aluminum alloys to high-temperature steel.

This makes it the furnace of choice for foundries that require frequent alloy changes, produce metal in batches, or need to melt scrap of varying shapes and sizes. The electromagnetic stirring is a key benefit for creating precise, homogenous alloys.

Understanding the Trade-offs

Neither design is without its limitations. Understanding these compromises is critical for selecting the right equipment and avoiding operational pitfalls.

The 'Heel' Requirement of Channel Furnaces

The biggest limitation of a channel furnace is that it cannot be started cold. It requires a continuous loop of molten metal—known as a "heel"—to complete the secondary circuit.

This makes it highly impractical for intermittent operation or frequent changes in the alloy being processed, as the furnace must be completely drained and painstakingly restarted with molten metal from another source.

The Lower Efficiency of Coreless Furnaces

Without an iron core to concentrate the magnetic field, the coupling between the coil and the charge in a coreless furnace is less efficient.

This means they generally require more power (kWh per ton) to melt metal compared to a channel furnace operating under ideal conditions. However, this is often an acceptable trade-off for their immense operational flexibility.

Refractory Wear and Maintenance

In a channel furnace, heat is concentrated in the small channel, leading to a thermal "hot spot" that causes intense, localized refractory wear.

In a coreless furnace, the stirring action that is so beneficial for metallurgy can also accelerate the erosion of the crucible's refractory lining over a larger surface area.

Making the Right Choice for Your Operation

Choosing the correct furnace requires a clear understanding of your production goals, the metals you work with, and your operational cadence.

- If your primary focus is continuous melting or holding a single alloy: The superior energy efficiency of a channel (core type) furnace makes it the definitive choice for large-scale, 24/7 operations.

- If your primary focus is batch melting, frequent alloy changes, or high-melting-point metals: The operational flexibility, cold-start capability, and metallurgical benefits of a coreless furnace are indispensable.

- If your primary focus is starting a new foundry or requiring maximum versatility: A coreless furnace provides the widest operational window and is the standard for most jobbing and alloy foundries.

Ultimately, your decision is a strategic choice between the specialized efficiency of a channel furnace and the versatile power of a coreless furnace.

Summary Table:

| Feature | Core Type (Channel) Furnace | Coreless Furnace |

|---|---|---|

| Core Design | Uses an iron core like a transformer | No iron core; uses a water-cooled copper coil |

| Primary Use | Holding & continuous melting of single alloy | Batch melting & frequent alloy changes |

| Efficiency | Very high (when operating continuously) | Lower than channel furnace |

| Flexibility | Low (requires a molten metal 'heel') | High (can start from a cold charge) |

| Ideal For | 24/7 operations (e.g., aluminum, copper) | Jobbing foundries, steel, versatile melting |

Still Unsure Which Induction Furnace is Right for Your Lab or Foundry?

The choice between a core type and a coreless furnace is critical for your productivity and bottom line. At KINTEK, we specialize in providing the right lab equipment and consumables for your specific metal melting and processing challenges. Our experts can help you analyze your production goals, alloy requirements, and operational cadence to recommend the perfect solution.

Let KINTEK empower your operation with the right technology. Contact our specialists today for a personalized consultation!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- How does a high vacuum induction melting furnace optimize FATT50? Enhancing Metal Toughness and Purity

- What is the difference between resistance heating and induction heating? Choose the Right Method for Your Needs

- What are the limitations of vacuum casting? Understanding the Trade-offs for High-Purity Manufacturing

- What is the induction melting method? A Guide to Clean, Efficient Metal Melting

- How is conventional heating different from induction heating? Direct vs. Indirect Heat Explained

- What are the advantages of coreless induction furnace? Achieve Clean, Precise, and Efficient Metal Melting

- Can cast iron be remelted? Yes, and Here's How to Do It Successfully

- What metals work with induction heating? Understanding Magnetic & Electrical Properties for Efficient Heating