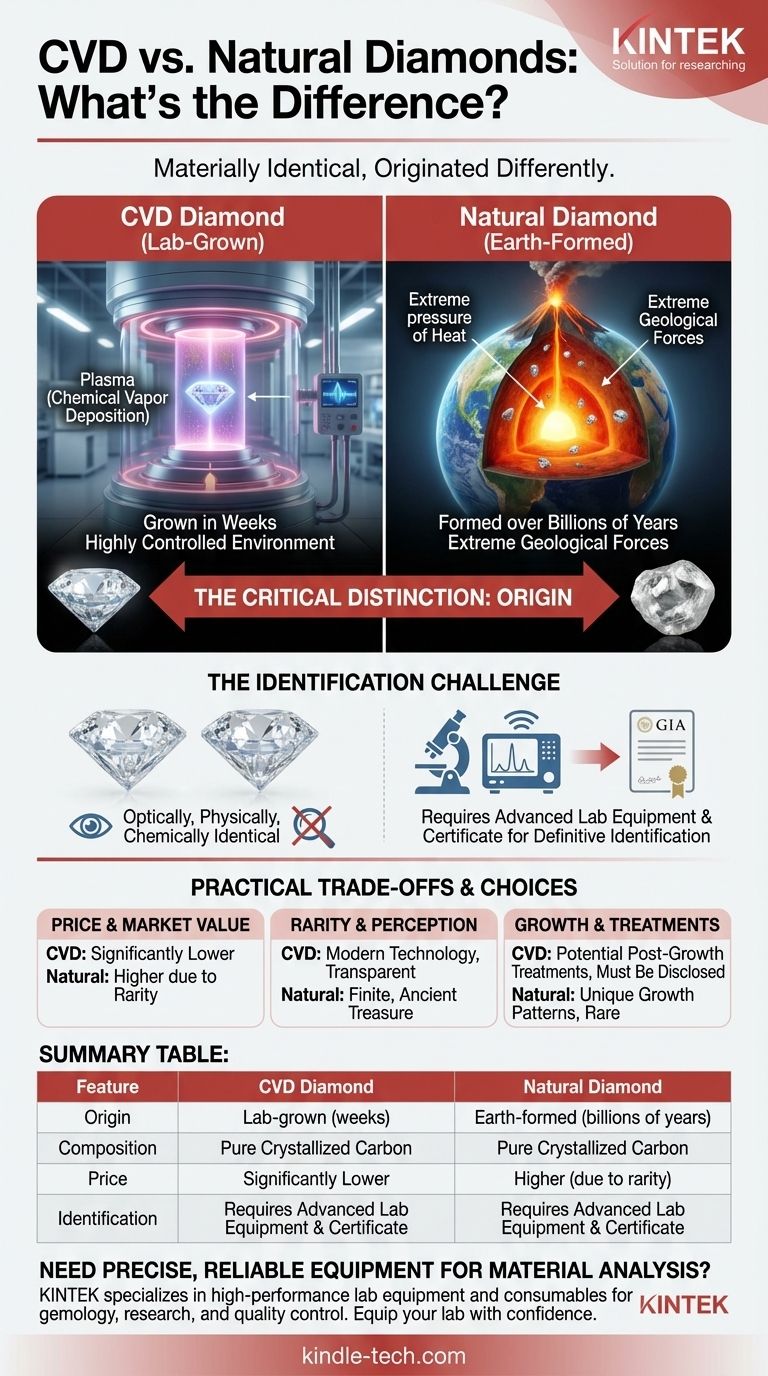

At their core, a lab-grown CVD diamond and a natural diamond are physically and chemically the same material. Both are crystallized carbon with identical hardness, brilliance, and composition. The only fundamental difference is their origin: one formed over billions of years deep within the Earth, while the other was grown in a highly controlled laboratory environment in a matter of weeks.

The critical distinction is not one of substance, but of origin. Because they are materially identical, the only way for a consumer to reliably tell them apart is through a gemological certificate which explicitly discloses the diamond's lab-grown status.

The Fundamental Distinction: Origin

The primary difference between CVD and natural diamonds is how and where they are formed. This distinction in origin is the source of all other differences, from market value to the subtle markers used for identification.

Natural Diamonds: Formed Over Billions of Years

Natural diamonds are a product of extreme geological forces. They formed deep within the Earth's mantle—over 100 miles below the surface—under immense pressure and intense heat. This process took place between 1 to 3 billion years ago, and these diamonds were later brought to the surface by violent volcanic eruptions.

CVD Diamonds: Grown in a Few Weeks

CVD stands for Chemical Vapor Deposition. This process begins with a small diamond "seed" crystal. The seed is placed in a vacuum chamber filled with a carbon-rich gas (like methane) and heated to high temperatures. Microwaves or another energy source break down the gas, allowing carbon atoms to rain down and deposit onto the seed, growing the diamond layer by layer.

The Identification Challenge

Because CVD and natural diamonds are optically, physically, and chemically identical, telling them apart is impossible for the naked eye and even for a trained jeweler using a standard loupe.

Why Standard Tools Aren't Enough

Simple observation cannot differentiate between the two. Both have the same refractive index, the same hardness on the Mohs scale (a perfect 10), and the same thermal conductivity. They look and feel identical.

The Role of Specialized Laboratories

Gemological laboratories like the GIA (Gemological Institute of America) use advanced scientific equipment to make a definitive identification. This machinery can detect the subtle differences in growth patterns and trace elements that are unique to each formation process. For example, the layered, directional growth of a CVD diamond looks different from the crystalline structure of a natural diamond under specific ultraviolet light.

The Certificate is Your Only Guarantee

For any consumer, the safest and most reliable way to know a diamond's origin is to review its official grading report or certificate. Reputable labs will always clearly state if a diamond is laboratory-grown in the comments section, often using terms like "CVD," "Lab-Grown," "As-Grown," or noting any post-growth treatments.

Understanding the Practical Trade-offs

Choosing between a CVD and a natural diamond involves considering factors beyond the physical stone itself. The decision often comes down to budget, ethics, and personal values.

Price and Market Value

Due to the efficiency of the manufacturing process and a virtually unlimited supply, CVD diamonds are significantly less expensive than natural diamonds of comparable size, color, and clarity. This makes larger or higher-quality stones more accessible.

Rarity and Perception

Natural diamonds derive much of their value from their finite supply and the geological miracle of their formation. They are marketed as rare, ancient treasures. CVD diamonds, on the other hand, represent a triumph of modern technology and can offer a more transparent and traceable supply chain.

Growth Characteristics and Treatments

Some CVD diamonds may undergo post-growth treatments, such as High-Pressure/High-Temperature (HPHT) annealing, to improve their color. These treatments are permanent and must be disclosed on the diamond's certificate, which is another reason why documentation is so critical.

Making the Right Choice for Your Goal

Your priorities will determine whether a CVD or natural diamond is the better option for you.

- If your primary focus is maximizing size and quality for a given budget: A CVD diamond will provide significantly more value and allow you to purchase a larger, higher-clarity stone than a natural diamond at the same price point.

- If your primary focus is traditional value and rarity: A natural diamond is the conventional choice, valued for its geological origin and position as a finite natural resource.

- If your primary focus is certainty and trust: Regardless of your choice, insist on a diamond graded by a reputable third-party laboratory to ensure its origin and quality characteristics are accurately documented.

Ultimately, your choice depends on what you value most, and with modern certification, you can make that decision with complete confidence.

Summary Table:

| Feature | CVD Diamond | Natural Diamond |

|---|---|---|

| Origin | Lab-grown (weeks) | Earth-formed (billions of years) |

| Composition | Pure Crystallized Carbon | Pure Crystallized Carbon |

| Price | Significantly Lower | Higher (due to rarity) |

| Identification | Requires Advanced Lab Equipment & Certificate | Requires Advanced Lab Equipment & Certificate |

Need precise, reliable equipment for material analysis?

Whether you're in gemology, research, or quality control, accurately identifying materials like diamonds requires trusted lab technology. KINTEK specializes in high-performance lab equipment and consumables, serving the precise needs of laboratories worldwide.

Let us help you equip your lab with confidence. Contact our experts today to find the perfect solution for your analytical challenges.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Domes for Industrial and Scientific Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

People Also Ask

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools