At its core, the primary difference between a hydraulic and a mechanical press is how they generate force. A hydraulic press uses pressurized fluid to create a consistent, controlled force throughout its entire stroke, while a mechanical press uses a motor-driven flywheel to store energy, which is then delivered in a powerful burst at the bottom of a fixed-length stroke.

The choice is not about which press is universally "better," but which is the right tool for the job. Hydraulic presses offer unmatched force control and flexibility, while mechanical presses deliver superior speed and repeatability for high-volume production.

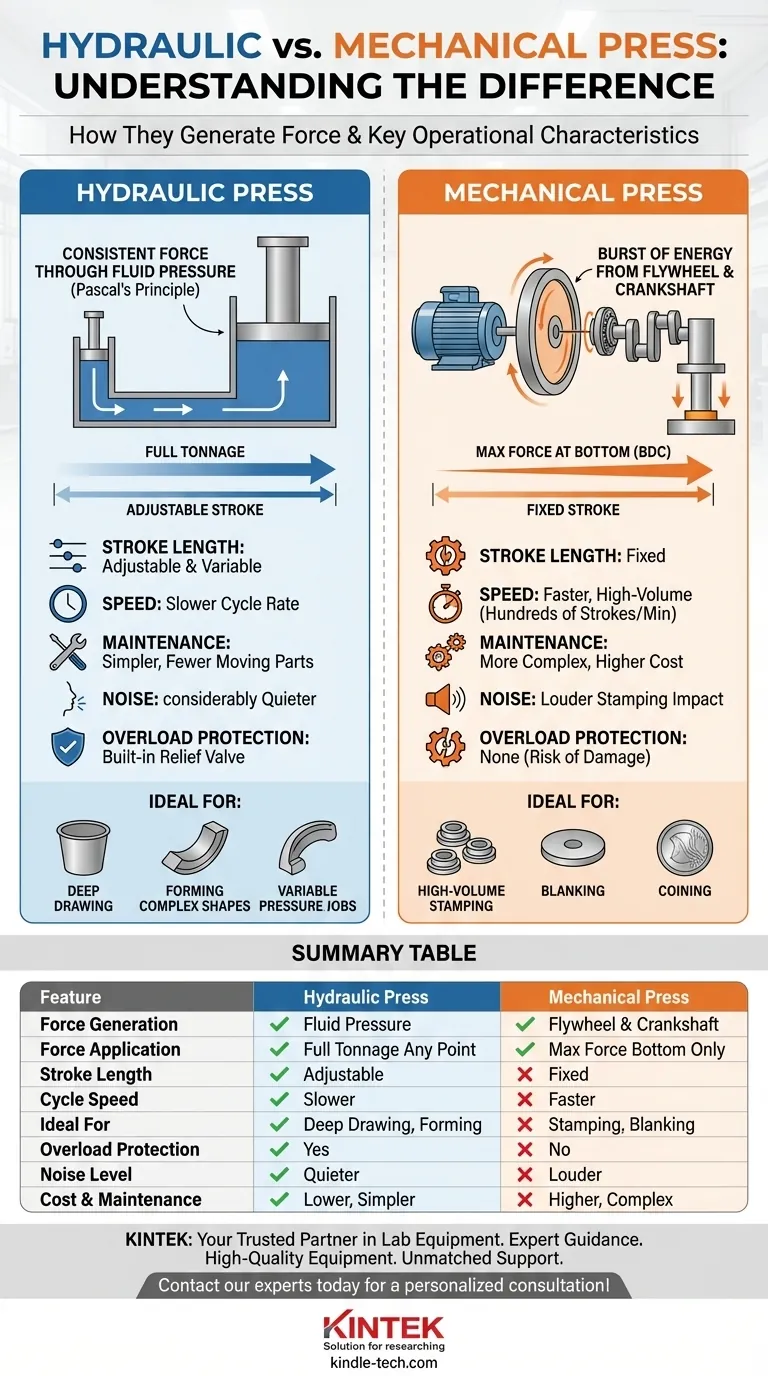

The Fundamental Difference: How They Generate Force

To understand their different applications, you must first grasp their distinct operating principles. Each method of generating force creates a unique set of advantages and limitations.

Hydraulic Presses: Consistent Force Through Fluid Pressure

A hydraulic press operates on Pascal's Principle, which states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In simple terms, a small amount of force applied to a small piston creates immense pressure in the hydraulic fluid. This pressure then acts on a much larger piston, multiplying the initial force significantly.

This method allows a hydraulic press to deliver its full, rated tonnage at any point in the ram's stroke, from the very top to the very bottom.

Mechanical Presses: A Burst of Energy from a Flywheel

A mechanical press functions more like a hammer. An electric motor spins a heavy flywheel, which stores a large amount of kinetic energy.

When the press is activated, a clutch engages and connects the spinning flywheel to a crankshaft. This crank mechanism drives the ram down in a fixed-length stroke.

The press delivers its maximum force only at the very bottom of its stroke, often called bottom dead center (BDC). The force available diminishes significantly anywhere else in the stroke.

Comparing Key Operational Characteristics

The differences in force generation directly impact performance, cost, and suitability for various tasks.

Force Control and Stroke Length

A key advantage of a hydraulic press is its full control over the stroke length and pressure. The operator can precisely adjust the ram's travel distance and the amount of force applied.

Mechanical presses, by contrast, have a fixed stroke length determined by the physical construction of the crankshaft. Force is not easily adjustable and is entirely dependent on the ram's position.

Speed and Cycle Rate

For high-volume, repetitive tasks like blanking or coining, mechanical presses are significantly faster. Their flywheel-based action is designed for rapid cycling, often achieving hundreds of strokes per minute.

Hydraulic presses are generally slower, as time is required to build and release fluid pressure for each cycle.

Initial Cost and Maintenance

As noted in industry analysis, hydraulic presses are often less expensive to purchase. Their design is simpler, with fewer moving parts.

This simplicity also translates to easier and cheaper maintenance. There are no complex clutches, gears, or brake systems to service.

Operational Noise

Hydraulic presses are considerably quieter than their mechanical counterparts. With fewer high-speed moving parts, the primary noise comes from the hydraulic pump, which is much less obtrusive than the stamping impact of a mechanical press.

Understanding the Trade-offs

Choosing a press requires an objective look at the inherent limitations of each design.

Overload Protection: A Key Hydraulic Advantage

A hydraulic press has built-in overload protection. A pressure relief valve prevents the system from exceeding its set tonnage, protecting both the press and the tooling from damage.

A mechanical press has no such protection. If it encounters a force greater than its capacity (e.g., a double-fed part), it will attempt to complete its stroke, which can lead to catastrophic failure of the frame or components.

Deep Drawing vs. Stamping

The consistent force of a hydraulic press makes it ideal for applications like deep drawing, where pressure must be applied evenly over a long stroke to form sheet metal without tearing.

The high speed and repeatable bottom-stroke accuracy of a mechanical press make it the superior choice for high-volume stamping, blanking, and coining operations.

The Rigidity of a Fixed Stroke

The fixed stroke of a mechanical press, while a limitation for flexibility, is an asset for precision. It ensures extreme repeatability at the bottom of the stroke, which is critical for consistent part quality in mass production.

The variable stroke of a hydraulic press offers versatility but may not provide the same level of high-speed positional accuracy as a mechanical press cycle after cycle.

Making the Right Choice for Your Application

Your final decision must be guided by the specific demands of your production goals.

- If your primary focus is deep drawing, forming complex shapes, or jobs requiring variable pressure: A hydraulic press is the superior choice due to its consistent force through the full stroke.

- If your primary focus is high-volume stamping, blanking, or coining: A mechanical press provides the speed and repeatability necessary for mass production.

- If your primary focus is budget, versatility, and operational safety: A hydraulic press is often the more accessible, flexible, and safer starting point for a wider range of tasks.

Ultimately, understanding the core principles of force application will empower you to select the press that functions as a true solution for your specific challenge.

Summary Table:

| Feature | Hydraulic Press | Mechanical Press |

|---|---|---|

| Force Generation | Fluid pressure (Pascal's Principle) | Flywheel & crankshaft |

| Force Application | Full tonnage at any point in stroke | Maximum force only at bottom of stroke |

| Stroke Length | Adjustable and variable | Fixed |

| Cycle Speed | Slower | Faster (ideal for high-volume) |

| Ideal For | Deep drawing, forming, variable pressure | Stamping, blanking, coining |

| Overload Protection | Yes (pressure relief valve) | No |

| Noise Level | Quieter | Louder |

| Initial Cost & Maintenance | Generally lower cost, simpler maintenance | Higher cost, more complex maintenance |

Still Unsure Which Press is Right for Your Lab?

Choosing between a hydraulic and mechanical press is critical for your productivity and results. KINTEK, your trusted partner in lab equipment, specializes in helping laboratories like yours select the perfect press for their specific applications—whether it's for material testing, sample preparation, or R&D prototyping.

We provide:

- Expert Guidance: Our specialists will analyze your needs to recommend the optimal press type.

- High-Quality Equipment: From versatile hydraulic presses for precise force control to high-speed mechanical presses for repetitive tasks.

- Unmatched Support: Installation, training, and maintenance to keep your lab running smoothly.

Don't leave your production efficiency to chance. Contact our experts today for a personalized consultation and discover the KINTEK difference in performance and reliability!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy