The fundamental difference between a hydraulic and a mechanical press lies in how they generate force. A hydraulic press uses a pump to pressurize a fluid (like oil) to drive a ram, offering constant and controllable force throughout the entire stroke. A mechanical press, in contrast, uses a motor-driven flywheel to store kinetic energy, which is then transferred to the ram through a crankshaft, delivering its maximum force only at the very bottom of the stroke.

The central decision comes down to a choice between flexibility and speed. Hydraulic presses provide unparalleled control over force and stroke for a wide variety of jobs, while mechanical presses offer high speed and repeatability for high-volume production.

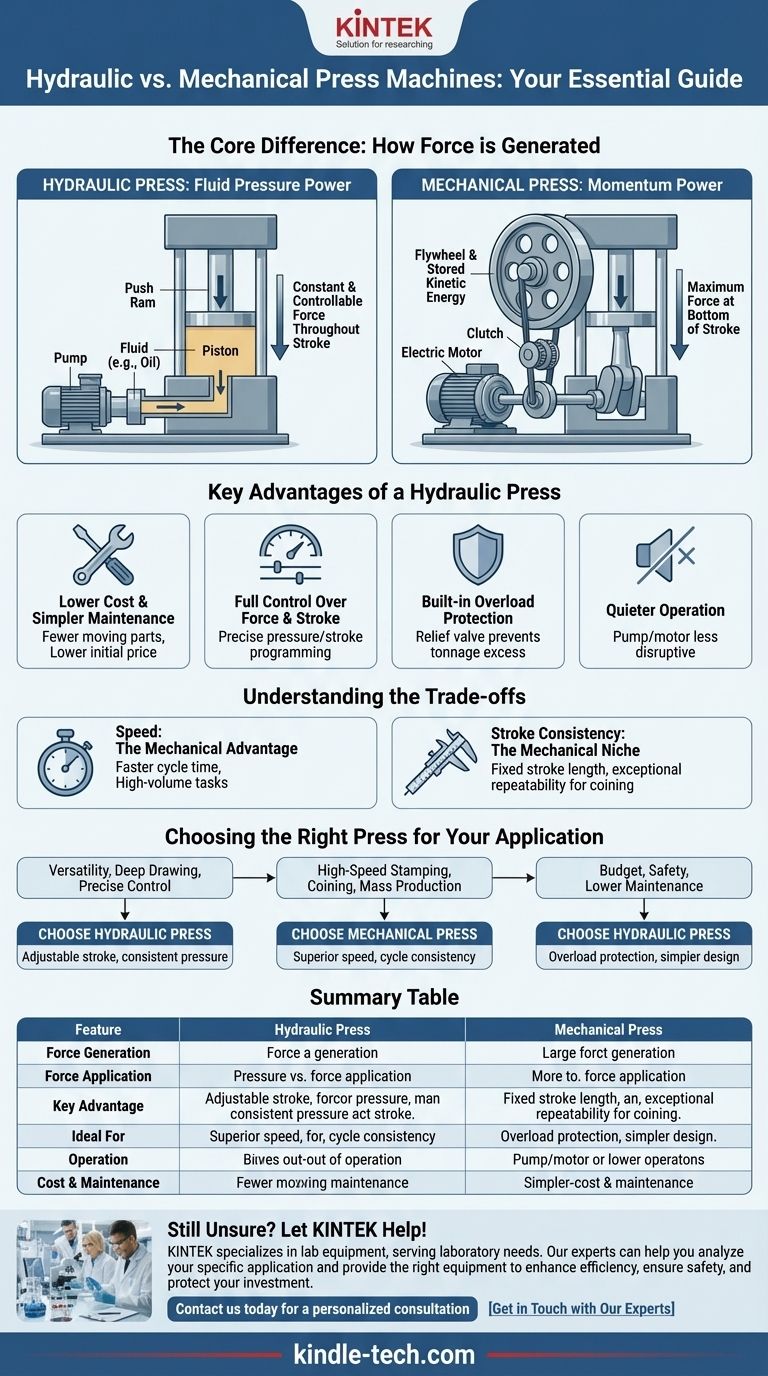

The Core Difference: How Force is Generated

To choose the right machine, you must first understand the mechanism that defines its capabilities. The method of force generation impacts everything from cost and control to safety and noise.

Hydraulic Press: The Power of Fluid Pressure

A hydraulic press operates on the principle of Pascal's Law. A pump pressurizes a confined fluid, and that pressure acts on a piston to generate a powerful, controlled downward force.

This design allows the press to generate its full rated tonnage at any point in the stroke, from the very top to the very bottom.

Mechanical Press: The Power of Momentum

A mechanical press uses a large, heavy flywheel that is kept in constant rotation by an electric motor.

When the operator engages the press, a clutch connects this spinning flywheel to a crankshaft. This converts the stored rotational energy into a powerful linear punch, but the maximum force is only achieved at the very end of the ram's travel.

Key Advantages of a Hydraulic Press

The references highlight several clear benefits that stem directly from the fluid power design of a hydraulic press. These advantages make it a superior choice for many applications.

Lower Cost and Simpler Maintenance

Hydraulic presses have a simpler design with significantly fewer moving parts compared to their mechanical counterparts.

This simplicity translates to a lower initial purchase price and reduced maintenance costs over the life of the machine, as there are fewer components to wear out or break.

Full Control Over Force and Stroke

The operator has precise, adjustable control over the pressure, meaning the force can be set and held constant. The stroke length, speed, and return position are all easily programmable.

This makes hydraulic presses ideal for applications requiring delicate force control or deep drawing, where consistent pressure over a long distance is critical.

Built-in Overload Protection

A hydraulic system is inherently protected from overload. It has a pressure relief valve that prevents the machine from ever exceeding its set tonnage.

This is a critical safety feature that protects not only the operator but also the expensive dies and the press frame itself from catastrophic damage. A mechanical press can get stuck or break if overloaded.

Quieter Operation

With no flywheel, clutch, or brake constantly in motion, hydraulic presses are substantially quieter than mechanical presses.

The primary sound comes from the pump and motor, which are much less disruptive than the shock and vibration of a mechanical press cycling at high speed.

Understanding the Trade-offs

While a hydraulic press offers significant flexibility, a mechanical press holds a distinct advantage in specific scenarios. Understanding this trade-off is key to an informed decision.

Speed: The Mechanical Advantage

For high-volume, repetitive tasks like blanking or punching thin material, a mechanical press is unmatched in speed. Its cycle time is typically much faster than a hydraulic press.

If your primary metric is parts per minute, a mechanical press will almost always outperform a hydraulic one.

Stroke Consistency: The Mechanical Niche

A mechanical press has a fixed stroke length determined by its crankshaft. This provides exceptional repeatability, delivering the exact same shut height with every cycle.

This consistency is crucial for coining or bottoming operations where the final material thickness is the most important factor.

Choosing the Right Press for Your Application

Your final decision should not be based on which press is "better," but on which press is better suited to the specific demands of your work.

- If your primary focus is versatility, deep drawing, or jobs requiring precise force control: Choose a hydraulic press for its adjustable stroke and consistent pressure.

- If your primary focus is high-speed stamping, coining, or mass production of simple parts: Choose a mechanical press for its superior speed and cycle-to-cycle consistency.

- If your primary focus is budget, safety, and lower maintenance: A hydraulic press offers built-in overload protection and a simpler design, making it an excellent choice.

Ultimately, aligning the machine's inherent capabilities with your production goals will ensure you have the right tool for the job.

Summary Table:

| Feature | Hydraulic Press | Mechanical Press |

|---|---|---|

| Force Generation | Fluid pressure (Pascal's Law) | Flywheel & crankshaft (kinetic energy) |

| Force Application | Full tonnage at any point in stroke | Maximum force only at bottom of stroke |

| Key Advantage | Control, flexibility, overload protection | Speed, high-volume repeatability |

| Ideal For | Deep drawing, forming, jobs requiring precise force | High-speed stamping, blanking, coining |

| Operation | Quieter, programmable stroke/speed | Louder, fixed stroke length |

| Cost & Maintenance | Lower initial cost, simpler maintenance | Higher initial cost, more complex maintenance |

Still Unsure Which Press is Right for Your Lab or Production Line?

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you analyze your specific application—whether it's delicate material testing requiring the precise control of a hydraulic press or high-throughput sample preparation needing the speed of a mechanical press.

We provide the right equipment to enhance your efficiency, ensure operator safety, and protect your investment.

Contact us today for a personalized consultation and let us help you make the perfect press choice for your unique requirements.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy