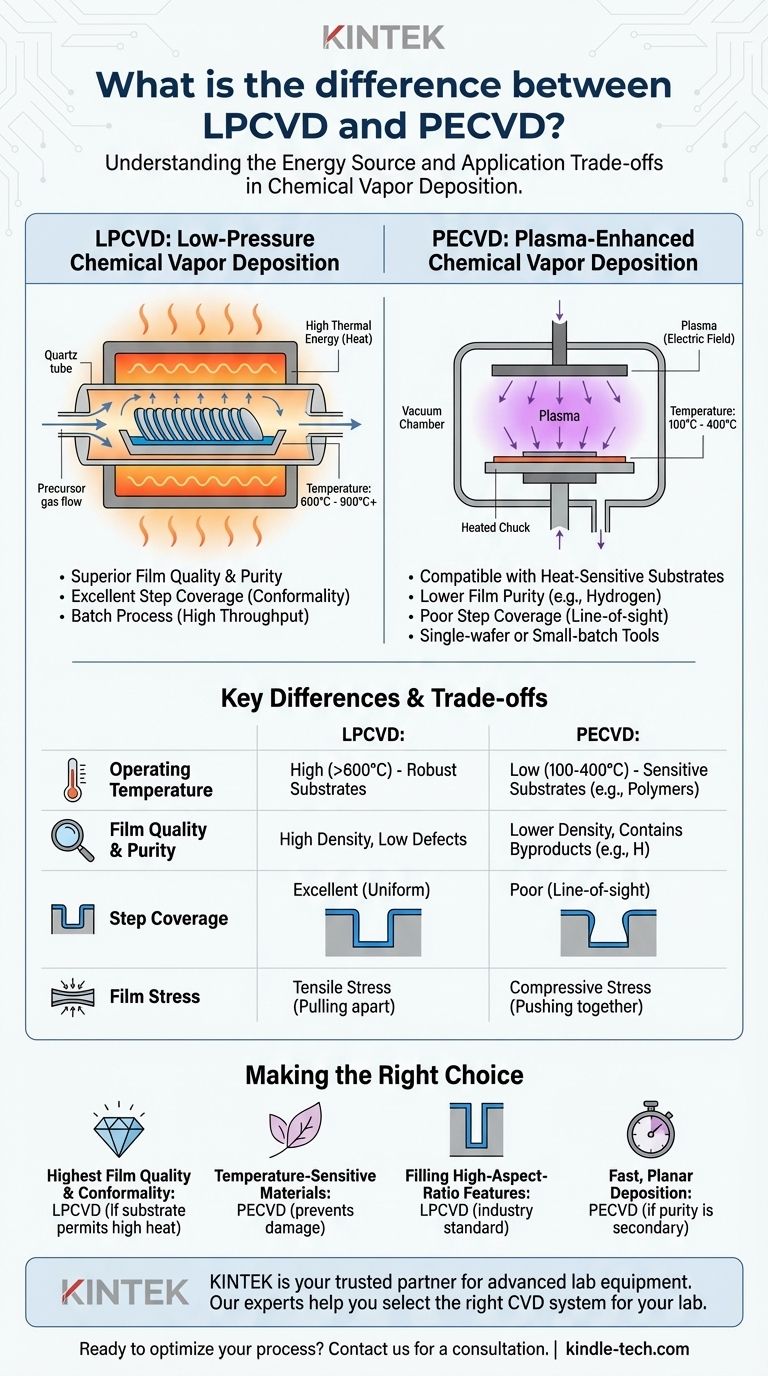

At its core, the difference between LPCVD and PECVD is how they energize the chemical reaction needed for film deposition. Low-Pressure Chemical Vapor Deposition (LPCVD) uses high thermal energy—heat—to drive the reaction. In contrast, Plasma-Enhanced Chemical Vapor Deposition (PECVD) uses energy from an electric field to create a plasma, allowing the process to run at much lower temperatures.

The choice is not about which method is universally better, but which is right for your specific goal. LPCVD delivers superior film quality and uniformity but requires high temperatures, while PECVD enables deposition on heat-sensitive materials at the cost of some film purity and conformality.

The Core Mechanism: Heat vs. Plasma

Both LPCVD and PECVD are types of Chemical Vapor Deposition (CVD), a process that builds a thin film on a substrate from gaseous precursors. The fundamental difference lies in the source of energy used to break apart these gas molecules and initiate the deposition.

How LPCVD Works: Thermal Energy

LPCVD relies on high temperatures, typically ranging from 600°C to over 900°C.

Precursor gases are introduced into a vacuum chamber containing the substrates. The intense heat provides the activation energy for the chemical reactions to occur, depositing a solid, uniform film on the substrate surface.

The "low pressure" aspect is critical, as it slows down gas-phase reactions and allows precursor molecules to spread out evenly, resulting in excellent film uniformity across many substrates at once.

How PECVD Works: Plasma Energy

PECVD sidesteps the need for extreme heat by using an electric field to ionize the precursor gases into a plasma.

This plasma is a highly energetic state of matter containing ions, electrons, and reactive radicals. These reactive species bombard the substrate surface and deposit the film at much lower temperatures, often between 100°C and 400°C.

Key Differences in Process and Outcome

The choice between heat and plasma creates significant differences in the final film's properties and the applicable substrates.

Operating Temperature and Substrate Compatibility

This is the most critical distinction. LPCVD's high heat restricts its use to thermally robust substrates, such as silicon wafers, that can withstand the processing without damage.

PECVD's low-temperature nature makes it suitable for depositing films on materials that would melt or be destroyed by LPCVD, including plastics, polymers, and substrates with pre-existing metal layers.

Film Quality and Purity

LPCVD generally produces films of superior quality. The high temperature and vacuum environment result in dense, pure films with excellent stoichiometry and low defect counts.

PECVD films, due to the lower temperature, often incorporate byproducts like hydrogen. For example, a PECVD silicon nitride film can contain significant hydrogen, which alters its electrical and optical properties compared to a purer LPCVD nitride film.

Step Coverage (Conformality)

Step coverage describes how well a film coats complex, three-dimensional surface features.

LPCVD provides outstanding conformality. The surface-reaction-limited nature of the process means the film grows at an almost equal rate on all surfaces, making it ideal for filling deep trenches and coating high-aspect-ratio structures in microelectronics.

PECVD has poor conformality. The plasma-driven process is more "line-of-sight," meaning it deposits more material on top surfaces than on sidewalls. It is best suited for depositing planar films on flat surfaces.

Understanding the Trade-offs

Choosing between these two methods requires a clear understanding of their inherent compromises.

Film Stress

The deposition method imparts internal stress on the film, which is a critical design consideration.

LPCVD films, such as silicon nitride, are typically under tensile stress (trying to pull apart). PECVD films are generally under compressive stress (trying to push together). This can dramatically affect the mechanical stability of your final device.

Process Throughput and Cost

Both methods require sophisticated, expensive equipment and cleanroom facilities. However, their operating models differ.

LPCVD is typically a batch process, with tube furnaces capable of processing 100+ wafers simultaneously. This gives it a very low cost-per-wafer, making it highly cost-effective for high-volume manufacturing.

PECVD systems are often single-wafer or small-batch tools. While the deposition rate can be faster than LPCVD, the overall throughput may be lower depending on the specific application.

Making the Right Choice for Your Application

Your decision must be guided by your primary objective and the limitations of your material.

- If your primary focus is the highest film quality and conformality: LPCVD is the superior choice, provided your substrate can withstand the high processing temperatures.

- If your primary focus is depositing on temperature-sensitive materials: PECVD is your only viable option, as its low-temperature plasma process avoids substrate damage.

- If your primary focus is filling high-aspect-ratio features: The excellent step coverage of LPCVD makes it the industry standard for this task.

- If your primary focus is a fast, planar deposition: PECVD can offer higher deposition rates and may be more efficient if absolute film purity and conformality are not the top priorities.

Ultimately, choosing between LPCVD and PECVD is a strategic decision that balances the demands of film performance with the thermal budget of your substrate.

Summary Table:

| Feature | LPCVD | PECVD |

|---|---|---|

| Energy Source | High Thermal Energy (Heat) | Plasma (Electric Field) |

| Typical Temperature | 600°C - 900°C+ | 100°C - 400°C |

| Best For | Superior film quality, high conformality | Temperature-sensitive substrates (e.g., polymers) |

| Film Stress | Tensile | Compressive |

| Process Type | Batch (High throughput) | Single-wafer/Small-batch |

Choose the Right Deposition Method for Your Lab

Understanding the trade-offs between LPCVD and PECVD is critical for your research and production outcomes. The right equipment ensures optimal film quality, substrate compatibility, and process efficiency.

KINTEK is your trusted partner for advanced lab equipment. We specialize in providing high-quality CVD systems and consumables tailored to your specific laboratory needs. Whether you require the superior film quality of LPCVD or the low-temperature capabilities of PECVD, our experts can help you select the perfect solution to enhance your workflow and achieve reliable, repeatable results.

Ready to optimize your thin-film deposition process? Contact our team today for a personalized consultation and discover how KINTEK can support your innovation.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Spark Plasma Sintering Furnace SPS Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- Are all lab grown diamonds CVD? Understanding the Two Main Methods

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit

- What are nanotubes drawbacks? The 4 Major Hurdles Limiting Their Real-World Use

- What is the floating catalyst method? A Guide to High-Yield CNT Production