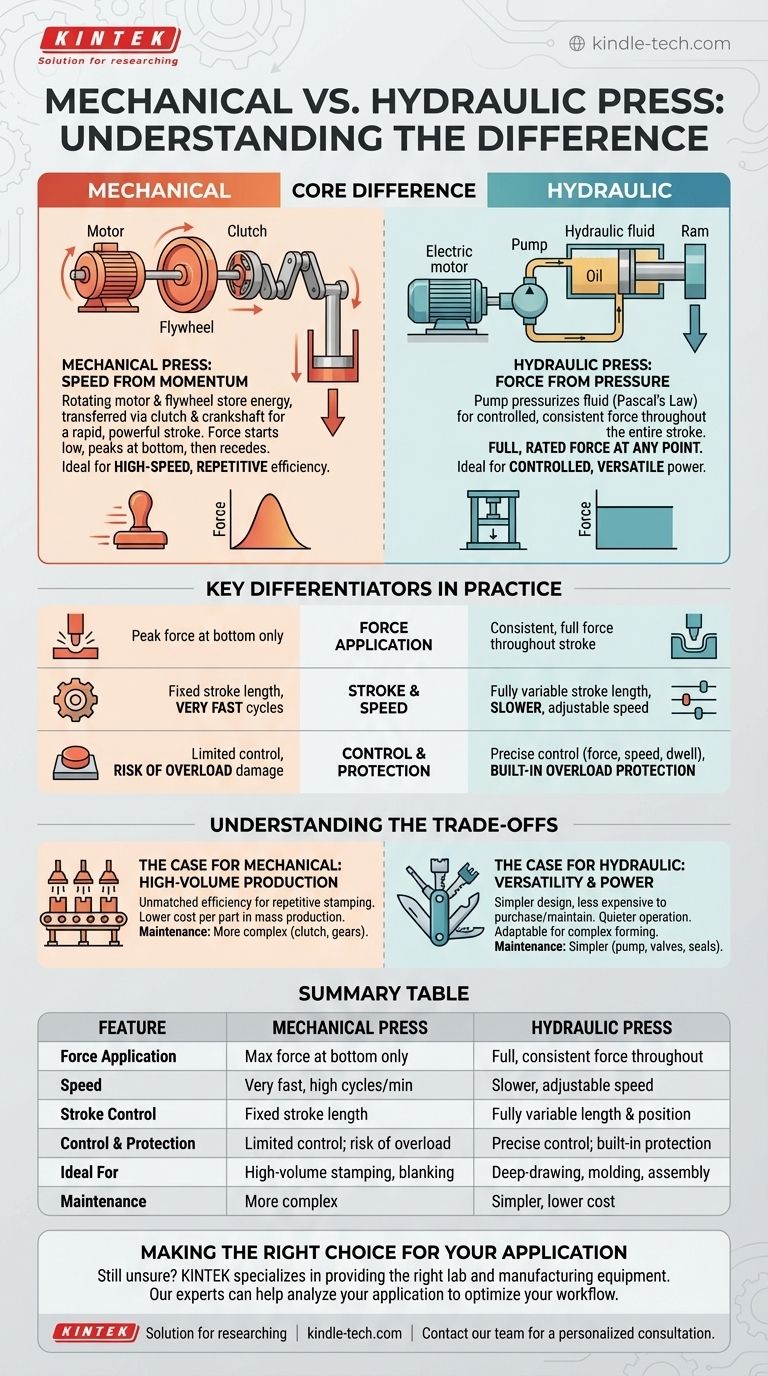

At its core, the difference between a mechanical and a hydraulic press is how each machine generates and delivers force. A mechanical press uses a rotating motor connected to a flywheel to store energy, which is then transferred through a clutch and crankshaft to deliver a fast, powerful stroke. In contrast, a hydraulic press uses a pump to pressurize fluid (typically oil) within a cylinder, generating a controlled and consistent force throughout its entire stroke.

The choice between them is not about which is "better," but which is right for your specific application. The decision hinges on a primary trade-off: the high-speed, repetitive efficiency of a mechanical press versus the controlled, versatile power of a hydraulic press.

How They Work: The Core Difference

The method of force generation dictates every other characteristic of the press, from its speed and control to its ideal use case.

The Mechanical Press: Speed from Momentum

A mechanical press functions much like the engine of a car. A continuously spinning flywheel stores kinetic energy.

When the operator engages the press, a clutch connects the flywheel to a crankshaft, which drives a ram down in a rapid motion.

The force is not constant; it starts low, builds to its maximum tonnage near the very bottom of the stroke, and then recedes as the ram retracts. This makes it exceptionally fast and efficient for high-volume, repetitive work.

The Hydraulic Press: Force from Pressure

A hydraulic press operates on a simple principle known as Pascal's Law: pressure applied to a confined fluid is transmitted undiminished throughout the fluid.

An electric motor drives a pump, which moves hydraulic oil into a cylinder, pushing against a piston. This action moves the ram.

Because the pressure is generated by the fluid, the press can deliver its full, rated force at any point in the stroke. The force, speed, and even the length of the stroke are fully adjustable.

Key Differentiators in Practice

Understanding the core mechanics reveals the practical differences you will experience on the shop floor.

Force Application

A mechanical press delivers its maximum force only at the bottom dead center of its stroke. This is ideal for "punching" operations like blanking, coining, and shallow stamping.

A hydraulic press delivers consistent, full force throughout its stroke. This is critical for applications that require sustained pressure, such as deep-drawing, molding, or assembly operations.

Stroke and Speed

Mechanical presses have a fixed stroke length and are significantly faster in terms of cycles per minute, making them the standard for high-volume production.

Hydraulic presses have a fully variable stroke length. While generally slower, their speed can be precisely controlled—allowing for a rapid advance, a slowed-down working stroke, and a rapid return.

Control and Built-in Protection

Control is the defining advantage of a hydraulic press. You can precisely set and adjust the ram force, speed, stroke distance, and dwell time (how long the press holds pressure at the bottom).

They also feature inherent overload protection. The system's relief valve prevents the press from ever exceeding the set pressure, protecting both the tooling and the machine itself. A mechanical press can be overloaded, potentially causing catastrophic damage.

Understanding the Trade-offs

Each press type comes with a distinct set of advantages and disadvantages tied directly to its design.

The Case for Hydraulic: Versatility and Power

Due to their simpler design with fewer moving parts, hydraulic presses are generally less expensive to purchase and maintain.

Their simplicity also means they are less prone to breakdowns and are significantly quieter in operation than the clatter of a mechanical press. This versatility makes them a jack-of-all-trades for job shops and applications requiring complex forming.

The Case for Mechanical: High-Volume Production

For high-speed, repetitive tasks like stamping simple parts from a coil of metal, a mechanical press is unmatched in its efficiency. Its speed translates directly to a lower cost per part in mass-production scenarios.

Maintenance and Upkeep

A hydraulic press is straightforward to troubleshoot. Problems are typically isolated to the pump, seals, or valves.

A mechanical press has more complex moving parts—clutch, brake, gears, bearings—that require regular lubrication and are more costly to repair or replace when they wear out.

Making the Right Choice for Your Application

Selecting the correct press is essential for optimizing your manufacturing process. Your choice should be driven by the primary requirement of the job.

- If your primary focus is high-speed, repetitive stamping or blanking: A mechanical press is the definitive choice for its unmatched cycle speed and efficiency.

- If your primary focus is deep-drawing, molding, or complex forming: A hydraulic press is required for its ability to deliver consistent force throughout the stroke.

- If your primary focus is versatility for a variety of jobs: A hydraulic press offers superior control over force, speed, and stroke, making it adaptable to many tasks.

- If your primary focus is precision assembly or force-sensitive work: A hydraulic press provides the fine control and built-in overload protection needed to prevent damage.

Ultimately, your decision comes down to a clear choice between the high-speed efficiency of mechanical power and the flexible control of hydraulic power.

Summary Table:

| Feature | Mechanical Press | Hydraulic Press |

|---|---|---|

| Force Application | Maximum force at bottom of stroke only | Full, consistent force throughout the entire stroke |

| Speed | Very fast, high cycles per minute | Slower, but speed is adjustable |

| Stroke Control | Fixed stroke length | Fully variable stroke length and position |

| Control & Protection | Limited control; risk of overload damage | Precise control of force, speed, dwell; built-in overload protection |

| Ideal For | High-volume stamping, blanking, punching | Deep-drawing, molding, complex forming, assembly |

| Maintenance | More complex (clutch, gears, bearings) | Simpler (pump, valves, seals); generally lower cost |

Still unsure which press is right for your operation? The choice between high-speed mechanical efficiency and versatile hydraulic control is critical for your productivity and part quality. At KINTEK, we specialize in providing the right lab and manufacturing equipment for your specific needs. Our experts can help you analyze your application—whether it's high-volume stamping or precision molding—to ensure you get a press that optimizes your workflow and protects your investment.

Contact our team today for a personalized consultation and discover how KINTEK's solutions can power your success.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual Lab Heat Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis