At its core, nitriding is a category of heat treatment processes that diffuse nitrogen into a metal's surface to create a hardened case. Plasma nitriding, also known as ion nitriding, is a specific and more advanced method within this category that uses ionized gas in a vacuum to achieve this effect, offering superior control and quality compared to traditional gas-based methods.

The fundamental difference is not the outcome, but the method of delivery. Traditional nitriding relies on a thermal-chemical reaction in a gas furnace, while plasma nitriding uses an electro-physical process of ion bombardment, providing precise control over the resulting hardened layer.

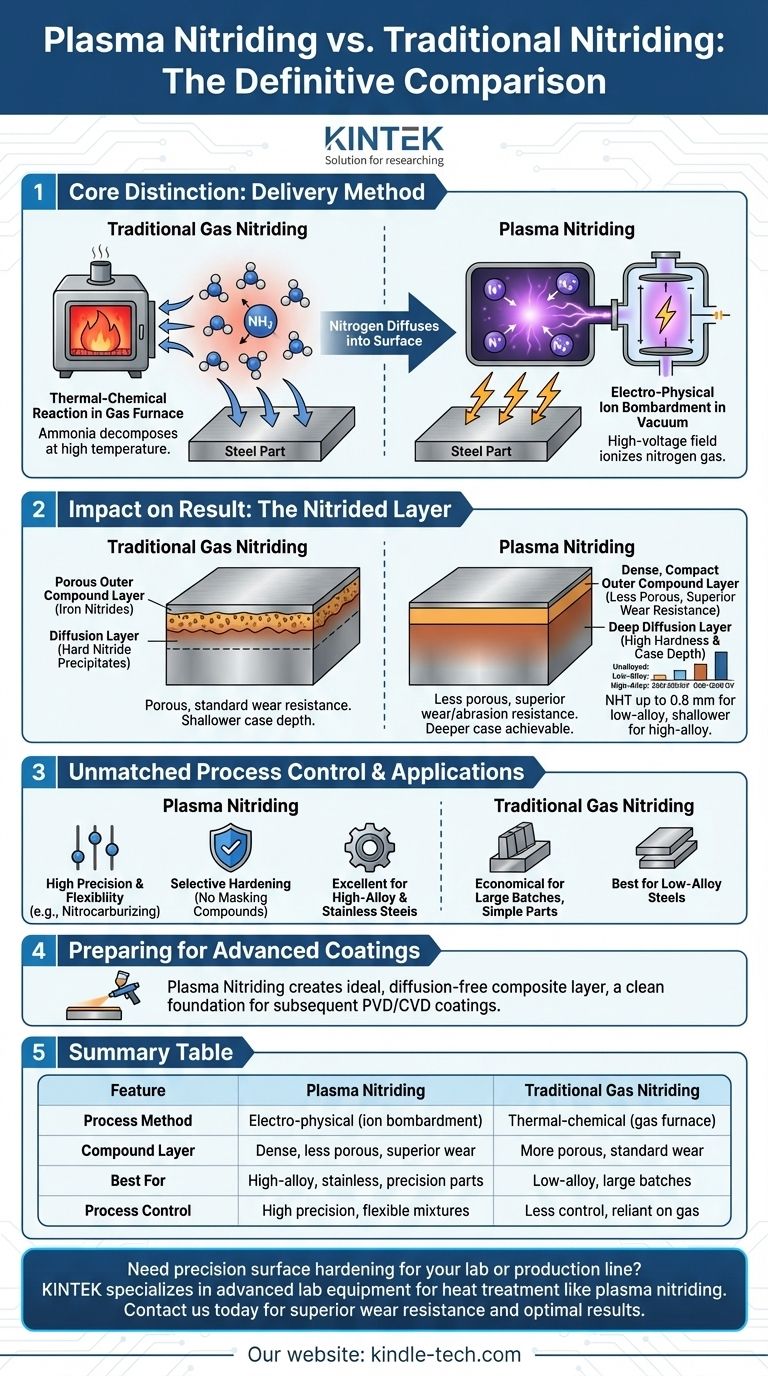

The Core Distinction: How Nitrogen Reaches the Surface

The method used to introduce nitrogen to the workpiece is the primary differentiator and dictates the advantages and disadvantages of each process.

Traditional Gas Nitriding: A Chemical Approach

Gas nitriding, the most common traditional form, involves heating parts in a sealed furnace filled with a nitrogen-rich gas, typically ammonia (NH3).

At high temperatures, the ammonia decomposes, releasing active nitrogen atoms that are absorbed by the steel surface and diffuse inward.

Plasma Nitriding: An Electro-Physical Approach

Plasma nitriding takes place in a vacuum vessel. A high-voltage electrical field is applied, stripping electrons from the low-pressure nitrogen and hydrogen gas mixture and creating an energized, ionized gas known as plasma.

These positively charged nitrogen ions are then accelerated by the electric field, bombarding the workpiece. This bombardment heats the part and delivers nitrogen directly into the surface with high efficiency and control.

How the Process Difference Impacts the Result

This distinction in delivery mechanism leads to significant differences in the final properties of the nitrided layer, which consists of two main zones.

The Outer Compound Layer

This outermost layer, composed of iron nitrides (ε and γ’), is the first line of defense against wear.

In plasma nitriding, this layer is characteristically more compact and less porous than one produced by gas nitriding. This dense structure provides superior resistance to wear, abrasion, and galling and is less prone to chipping.

The Inner Diffusion Layer

Beneath the compound layer, nitrogen diffuses deeper into the material, forming hard nitride precipitates with alloying elements in the steel. This is what creates the "case depth."

The hardness achieved depends heavily on the steel's composition. For example:

- Unalloyed Steels: 250-300 HV

- Low-Alloy Steels: 600-700 HV

- High-Alloy Steels: 800-1200 HV

Typical case depths (NHT) can reach up to 0.8 mm for low-alloy steels but are often shallower (under 0.15 mm) for high-alloy steels due to their dense structure.

Unmatched Process Control

The plasma environment allows for precise management of the gas mixture. Adding a small amount of a carbon-containing gas like methane transforms the process into plasma nitrocarburizing.

This flexibility allows for creating tailored compound layers, like the hard epsilon (ε) layer, which is particularly effective for unalloyed steels and cast irons.

Understanding the Practical Trade-offs

Choosing between plasma and traditional nitriding involves weighing precision and performance against simplicity and cost.

When to Consider Gas Nitriding

Gas nitriding is an established, robust process that can be more economical for large batches of simple, low-alloy steel components where the absolute highest performance is not the primary driver.

The Advantages of Plasma Nitriding

Plasma nitriding is the superior choice for high-performance applications. It excels with high-alloy and stainless steels, which are difficult to treat with gas methods.

The plasma process also allows for selective hardening without the need for physical masking compounds, as shields can be used to control where the plasma forms.

Preparing for Advanced Coatings

A key industrial advantage of plasma nitriding is its ability to produce a diffusion-free composite layer. This clean, dense surface is the ideal foundation for subsequent Physical Vapor Deposition (PVD) or Chemical Vapor Deposition (CVD) coatings.

Making the Right Choice for Your Application

The best method depends entirely on your material, part geometry, and performance requirements.

- If your primary focus is cost-effective hardening for simple, low-alloy steel parts: Traditional gas nitriding is often a sufficient and economical choice.

- If your primary focus is maximum hardness and wear resistance on high-alloy or stainless steels: Plasma nitriding offers superior control and produces a higher quality, denser surface.

- If your primary focus is preparing a part for a subsequent PVD or CVD coating: Plasma nitriding is the preferred method for creating the ideal, non-porous foundation.

By understanding these fundamental process differences, you can select the precise surface treatment to achieve your specific engineering goals.

Summary Table:

| Feature | Plasma Nitriding | Traditional Gas Nitriding |

|---|---|---|

| Process Method | Electro-physical (ion bombardment in vacuum) | Thermal-chemical (gas furnace) |

| Compound Layer | Dense, less porous, superior wear resistance | More porous, standard wear resistance |

| Best For | High-alloy steels, stainless steels, precision parts | Low-alloy steels, cost-effective large batches |

| Process Control | High precision, flexible gas mixtures (e.g., nitrocarburizing) | Less control, reliant on gas chemistry |

Need precision surface hardening for your lab or production line? KINTEK specializes in advanced lab equipment and consumables for heat treatment processes like plasma nitriding. Our solutions help you achieve superior wear resistance, precise control, and optimal results for high-performance materials. Contact us today to discuss how our expertise can enhance your laboratory's capabilities!

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- 1700℃ Laboratory Quartz Tube Furnace with Alumina Tube Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the plasma sintering method? Unlock Rapid, High-Density Material Fabrication

- What is spark plasma sintering of polymers? Rapidly Create Dense, High-Performance Materials

- What are the applications of spark plasma sintering? Fabricate High-Performance Materials with Precision

- What is the process of plasma sintering? Achieve Rapid, High-Performance Material Densification

- What is spark plasma sintering process? Fast-Track to Dense, Fine-Grained Materials