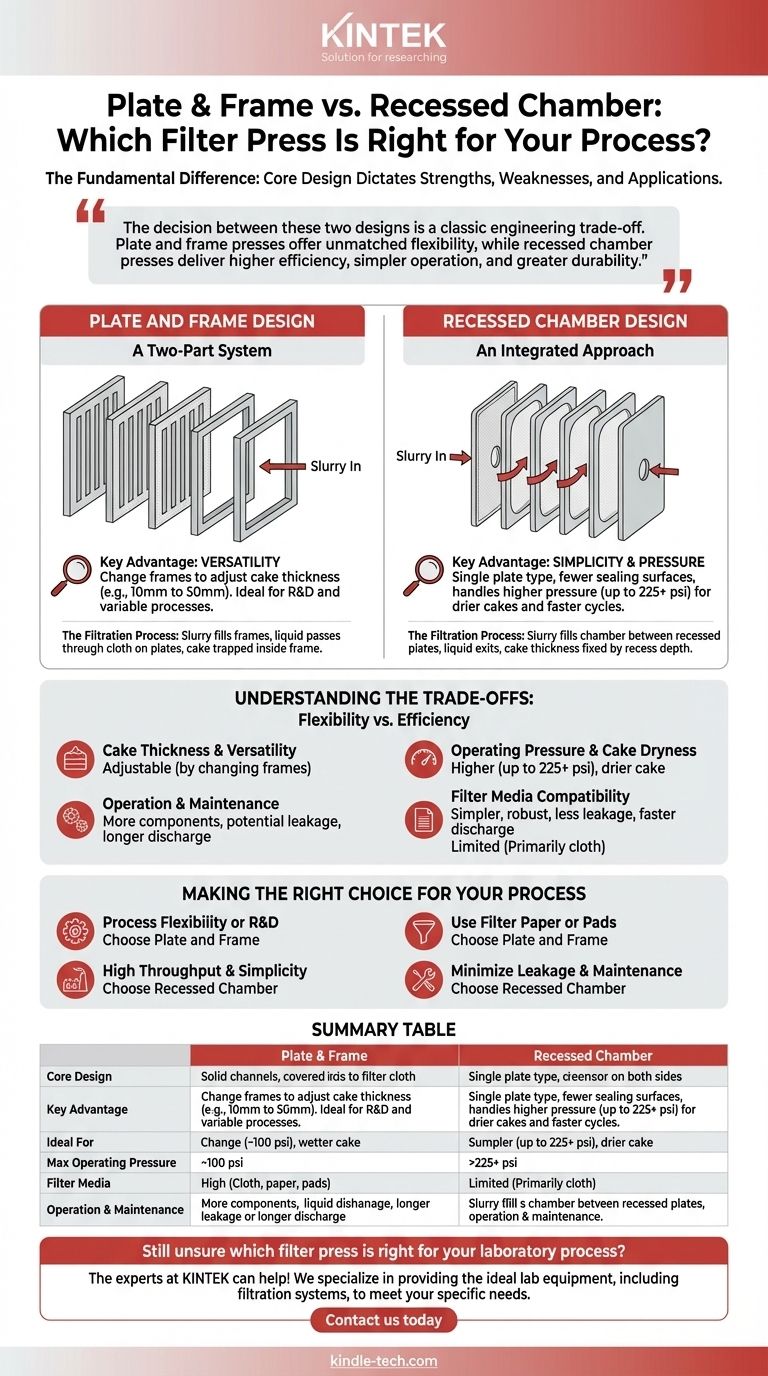

The fundamental difference between a plate and frame filter press and a recessed chamber press lies in the construction of the filter plates themselves. A plate and frame press uses a two-part system of flat solid plates and hollow frames to create a chamber for solids. In contrast, a recessed chamber press uses a single type of plate with a depression on each side, which forms the chamber when two plates are pressed together. This core design difference dictates their respective strengths, weaknesses, and ideal applications.

The decision between these two designs is a classic engineering trade-off. Plate and frame presses offer unmatched flexibility for varying process conditions, while recessed chamber presses deliver higher efficiency, simpler operation, and greater durability for consistent, high-volume production.

The Plate and Frame Design: A Two-Part System

The plate and frame filter press is the original design, characterized by its modular, two-component structure.

How It's Constructed

This press consists of two distinct types of plates that are arranged alternately in a pack: solid plates and hollow frames.

A sheet of filter cloth is draped over each solid plate. When the plate pack is compressed, the hollow frame between two cloth-covered plates creates a sealed chamber.

The Filtration Process

Slurry is pumped into the hollow frames. The liquid phase passes through the filter cloth on either side, flows down channels in the solid plate, and exits the press.

The solid particles, or "cake," are trapped inside the frame. The thickness of the cake is determined entirely by the thickness of the hollow frame.

Key Advantage: Versatility

The defining strength of the plate and frame design is its flexibility. By simply swapping out the frames for ones of a different thickness, you can easily change the volume of the chamber and thus the thickness of the filter cake. This makes it ideal for research, pilot testing, or processes where the slurry composition varies significantly.

The Recessed Chamber Design: An Integrated Approach

The recessed chamber press is a more modern evolution designed for greater efficiency and simplicity in production environments.

How It's Constructed

This press uses only one type of plate. Each plate has a shallow, recessed depression on both faces, with a feed port in the center.

The filter cloth is cut to fit within this recess. When two plates are pressed together, the two recesses form a single, enclosed chamber.

The Filtration Process

Slurry is pumped through the central feed port and fills the chamber formed between two plates. The liquid passes through the cloth and exits, leaving the solid cake behind.

The cake thickness is fixed by the depth of the recess on the plates.

Key Advantage: Simplicity and Pressure

The recessed chamber design is mechanically simpler and more robust. With fewer sealing surfaces, it is less prone to leakage than the plate and frame model.

Crucially, its integrated design allows it to withstand much higher feed pressures. This results in a drier filter cake and often faster filtration cycle times.

Understanding the Trade-offs: Flexibility vs. Efficiency

Choosing the right press requires a clear understanding of the compromises between these two designs.

Cake Thickness and Versatility

The plate and frame press is the clear winner for processes requiring variable cake thickness. You can change frames to go from a 10mm cake to a 50mm cake with the same press.

A recessed chamber press has a fixed cake depth, determined by the plate design. Changing the cake thickness requires purchasing an entirely new set of plates, which is not practical.

Operating Pressure and Cake Dryness

The recessed chamber press is superior. Its robust, single-body plate design can handle significantly higher operating pressures (typically up to 225 psi or higher).

Higher pressure squeezes more liquid from the cake, resulting in a drier, more compact solid product. Plate and frame presses usually operate at lower pressures (around 100 psi) to prevent leakage.

Operation and Maintenance

The recessed chamber press is simpler to operate. Cake discharge is typically faster, and with only one type of plate to handle and clean, maintenance is more straightforward.

The plate and frame design has more components (plates and frames), increasing handling time during cake discharge and cleaning. It also has double the sealing surfaces, creating more potential points for leakage.

Filter Media Compatibility

A plate and frame press is more versatile with filter media. Its design can easily accommodate filter paper or disposable pads in addition to standard filter cloth. This is essential for applications requiring extremely fine filtration, such as in the beverage or pharmaceutical industries.

Making the Right Choice for Your Process

Your selection should be guided by the specific demands of your filtration task.

- If your primary focus is process flexibility or R&D: Choose a plate and frame press for its unmatched ability to adjust cake thickness by simply changing the frames.

- If your primary focus is high throughput and operational simplicity: A recessed chamber press is the better choice for its higher pressure tolerance, drier cakes, and faster, more reliable operation.

- If you need to use filter paper or pads instead of cloth: The plate and frame design is your only practical option for this type of media.

- If minimizing leakage and maintenance is your top priority: The integrated and robust design of the recessed chamber press makes it the more reliable choice for demanding production environments.

By understanding these fundamental design differences, you can select the precise tool required to achieve your specific separation goal.

Summary Table:

| Feature | Plate & Frame Press | Recessed Chamber Press |

|---|---|---|

| Core Design | Two-part system: solid plates & hollow frames | Single plate type with recessed depressions |

| Key Advantage | High flexibility (adjustable cake thickness) | High efficiency & simplicity |

| Ideal For | R&D, pilot testing, variable processes | Consistent, high-volume production |

| Max Operating Pressure | Lower (~100 psi) | Higher (up to 225+ psi) |

| Filter Media | Cloth, paper, or disposable pads | Primarily cloth |

| Operation & Maintenance | More components, higher leakage potential | Simpler, more robust, less prone to leakage |

Still unsure which filter press is right for your laboratory process? The experts at KINTEK can help! We specialize in providing the ideal lab equipment, including filtration systems, to meet your specific needs.

Contact us today for a personalized consultation to enhance your lab's efficiency and achieve superior separation results.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples