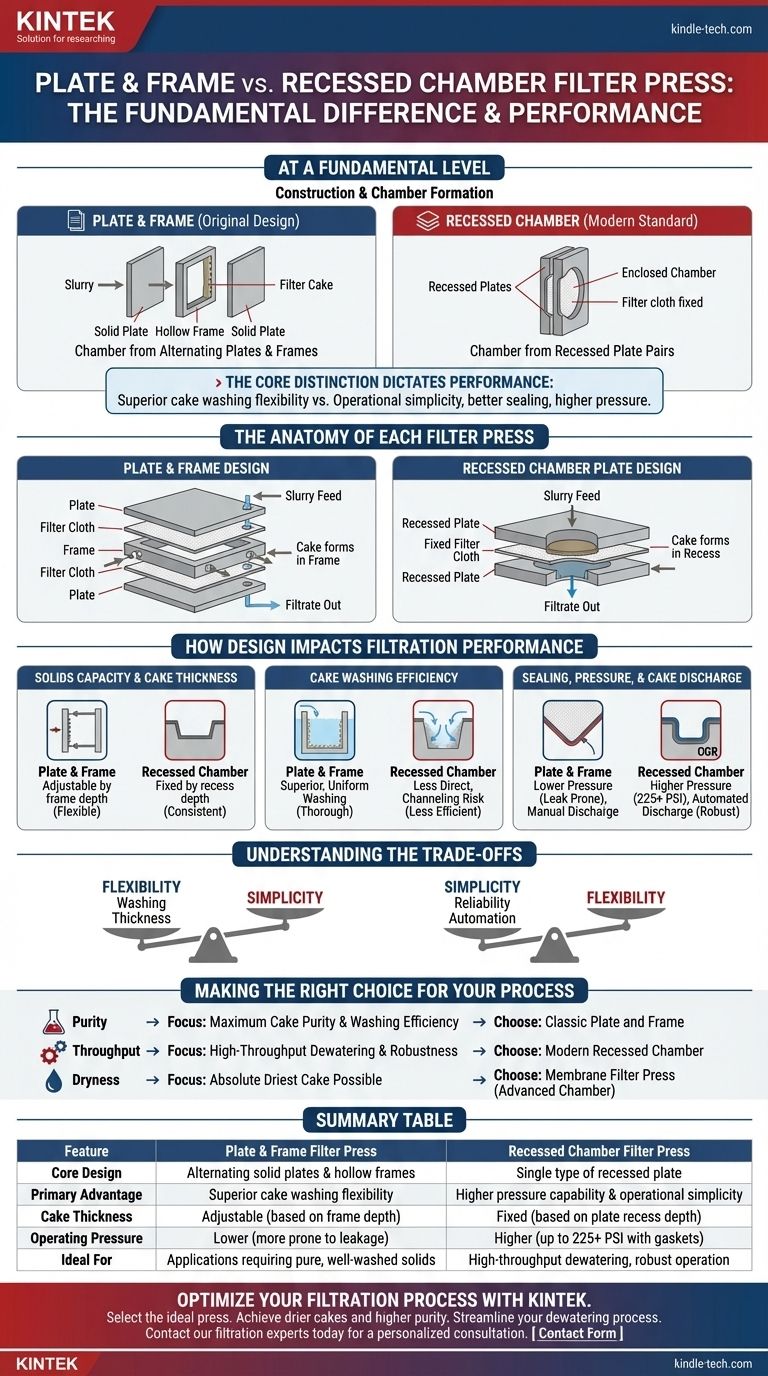

At a fundamental level, the difference lies in their construction and how they form the chamber for collecting solids. A classic plate and frame filter press uses a set of alternating solid plates and hollow frames, where the slurry fills the frame. The more modern and common design, a chamber filter press, uses a single type of recessed plate, where two adjacent plates create the chamber between them.

The core distinction is not merely academic; it dictates performance. The plate and frame design offers superior cake washing flexibility, while the recessed chamber design provides greater operational simplicity, better sealing, and higher pressure capabilities, making it the standard for most modern dewatering applications.

The Anatomy of Each Filter Press

To understand their performance differences, you must first visualize how each type is constructed. The names "plate and frame" and "recessed chamber" directly describe their core components.

The Plate and Frame Design (The Original)

A plate and frame press is assembled from two distinct components in an alternating sequence: a solid plate and a hollow frame.

The filter cloth is draped over the solid plates. When the press is closed, a plate and a frame are pushed together, creating a sealed chamber inside the hollow frame.

Slurry is pumped into this frame, filling it with solids (the filter cake) while the liquid (filtrate) passes through the cloth and out through ports in the plate.

The Recessed Chamber Plate Design (The Modern Standard)

A recessed chamber press uses only one type of component: a plate with a shallow, recessed depression on both sides.

When two of these recessed plates are pressed together, the depressions face each other and form a single, enclosed chamber. The filter cloth is typically fixed directly to the face of each plate.

This design is structurally simpler, as it eliminates the need for separate frames and reduces the total number of components in the press stack.

How Design Impacts Filtration Performance

The seemingly small difference in construction has significant consequences for how each press operates in a real-world industrial setting, affecting everything from efficiency to maintenance.

Solids Capacity and Cake Thickness

With a plate and frame press, the thickness of the filter cake is determined by the depth of the hollow frame. This offers the flexibility to change cake thickness by simply swapping out the frames for ones of a different depth.

In a recessed chamber press, the cake thickness is fixed by the depth of the recess molded into the plate. This is less flexible but provides consistent and predictable performance.

Cake Washing Efficiency

This is the primary area where the plate and frame design can excel. Its structure allows for more uniform and thorough cake washing, as wash liquid can be introduced to flood the entire frame, displacing the mother liquor more effectively. This is critical in applications where recovering a pure, well-washed solid is the main goal.

Chamber presses can also perform cake washing, but the flow path is less direct. There is a higher risk of "channeling," where wash water finds the path of least resistance and bypasses sections of the cake, leading to less efficient washing.

Sealing, Pressure, and Cake Discharge

The recessed chamber press is the clear winner in operational robustness. Modern designs often feature gasketed (CGR) plates that create a virtually leak-proof seal, allowing for much higher operating pressures (up to 225 PSI or higher). Higher pressure results in a drier filter cake.

The plate and frame design relies on the filter cloth itself to act as the primary gasket between the flat faces of the plates and frames. This makes it more prone to leakage ("wicking") at the edges and limits its maximum operating pressure.

Furthermore, cake discharge from a chamber press is simpler and more reliable, as the fixed cloths and plate design are better suited for automatic plate shifters and cloth vibration systems.

Understanding the Trade-offs

Choosing between these technologies is a matter of prioritizing competing goals. Neither is universally "better"; they are simply better for different objectives.

Flexibility vs. Simplicity

The classic plate and frame offers greater process flexibility, particularly in its ability to change cake thickness and its inherent advantage in thorough washing.

The recessed chamber press sacrifices this flexibility for immense gains in operational simplicity, reliability, and automation readiness. It has fewer parts, seals better, and requires less manual intervention.

Historical Context vs. Modern Application

The plate and frame design is the older technology. While still used in some niche applications (like fine chemicals or pharmaceuticals where washing is paramount), it has been largely superseded.

The recessed chamber design is the foundation for virtually all modern filter presses. Innovations like the membrane filter press—which adds a flexible diaphragm to squeeze the cake for maximum dewatering—are built upon the recessed chamber concept.

Making the Right Choice for Your Process

Your selection should be guided by a clear understanding of your primary operational goal.

- If your primary focus is maximum cake purity and washing efficiency: The classic plate and frame design may offer superior performance, making it a contender for specialized chemical or pharmaceutical processes.

- If your primary focus is high-throughput dewatering and operational robustness: A modern recessed chamber press is almost always the correct choice due to its better sealing, higher pressure capabilities, and lower maintenance needs.

- If your primary focus is achieving the absolute driest cake possible: You should look beyond the basic designs to a membrane filter press, a type of recessed chamber press that adds a final squeezing stage for ultimate dewatering.

Understanding these core design differences empowers you to select the filtration technology that aligns directly with your operational and product quality goals.

Summary Table:

| Feature | Plate & Frame Filter Press | Recessed Chamber Filter Press |

|---|---|---|

| Core Design | Alternating solid plates & hollow frames | Single type of recessed plate |

| Primary Advantage | Superior cake washing flexibility | Higher pressure capability & operational simplicity |

| Cake Thickness | Adjustable (based on frame depth) | Fixed (based on plate recess depth) |

| Operating Pressure | Lower (more prone to leakage) | Higher (up to 225+ PSI with gaskets) |

| Ideal For | Applications requiring pure, well-washed solids | High-throughput dewatering, robust operation |

Optimize Your Filtration Process with KINTEK

Choosing the right filter press is critical for your lab's efficiency and product quality. Whether your priority is superior cake washing with a plate and frame design or the high-pressure, low-maintenance operation of a modern recessed chamber press, KINTEK has the expertise and equipment to meet your specific laboratory needs.

Let us help you:

- Select the ideal press for your application and throughput requirements.

- Achieve drier cakes and higher purity with the right technology.

- Streamline your dewatering process with reliable, high-performance equipment.

Contact our filtration experts today for a personalized consultation and discover how our lab equipment solutions can enhance your results.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy