At its core, the difference between spark plasma sintering (SPS) and conventional sintering lies in the heating method. SPS uses a pulsed direct electrical current to heat the sample and its mold internally, enabling extremely rapid heating and consolidation. In contrast, conventional sintering relies on slow, external heating within a furnace, a process that takes significantly more time and energy.

The choice between these methods is not merely about speed; it's about material integrity. SPS's rapid, low-temperature process gives scientists and engineers unprecedented control, allowing them to preserve delicate nanostructures and create high-performance materials that are impossible to fabricate using conventional techniques.

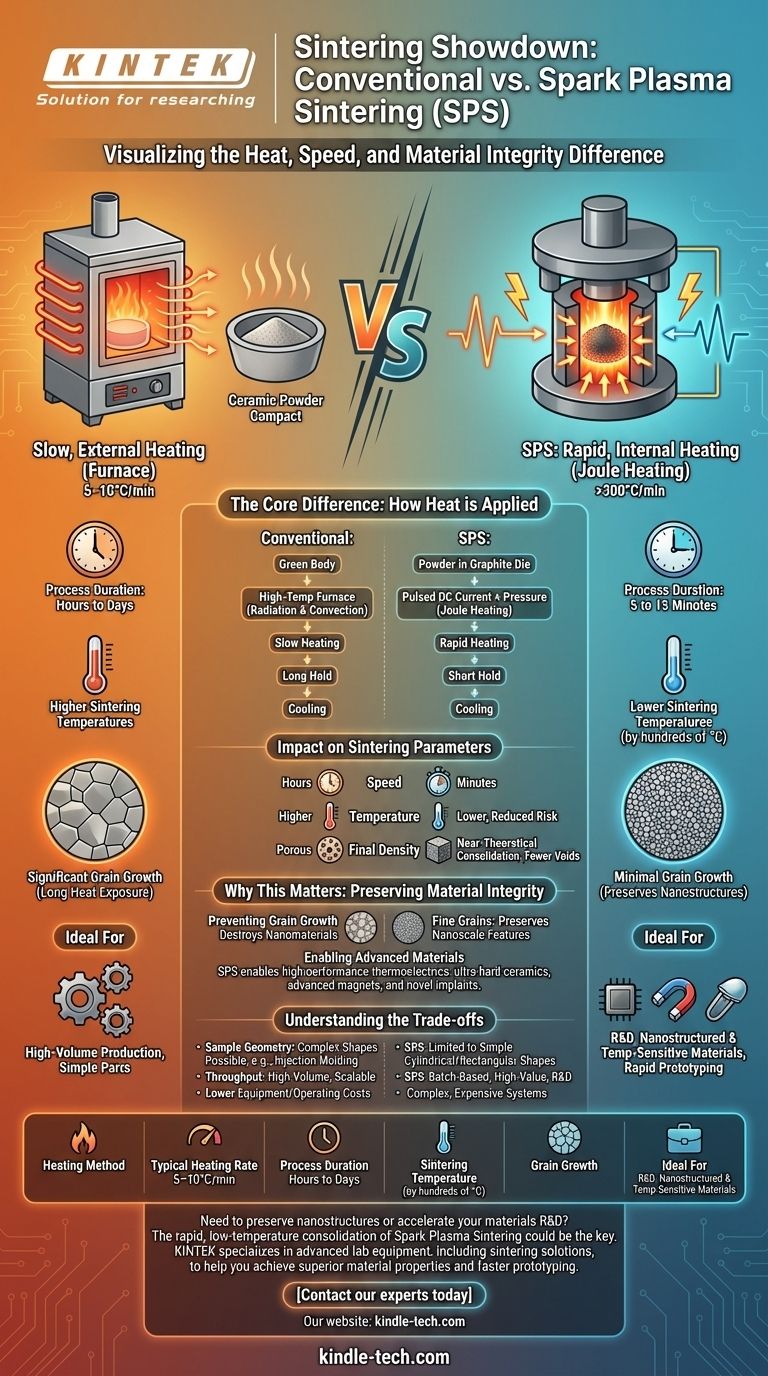

The Core Difference: How Heat is Applied

The fundamental distinction that drives all other advantages and disadvantages is the mechanism used to deliver thermal energy to the powdered material.

Conventional Sintering: Slow, External Heating

Conventional sintering places a pre-compacted part, often called a "green body," into a high-temperature furnace.

Heat is transferred from external heating elements to the part's surface via radiation and convection. This process is slow, with typical heating rates of 5–10°C per minute.

Spark Plasma Sintering: Rapid, Internal Heating

In SPS, the powder is placed in a graphite die, which is then subjected to both mechanical pressure and a high-amperage, pulsed direct current.

Heating is generated internally via Joule heating, as the electrical current passes through the conductive graphite die and, in some cases, the powder itself. This direct heating mechanism allows for incredibly high heating rates, often exceeding 300°C per minute.

The Impact on Sintering Parameters

This difference in heating method has profound consequences for the entire sintering process, from speed and temperature to the final quality of the material.

Speed: Hours vs. Minutes

Conventional sintering is a lengthy process. Reaching the target temperature can take several hours, and the material must be held there for an extended period to densify. The entire cycle can last from many hours to several days.

SPS is orders of magnitude faster. A target temperature of 1200°C can be reached in under five minutes. The total processing time, including heating, holding, and cooling, is often just 5 to 15 minutes.

Temperature: Lower Sintering Temperatures

Because pressure is applied simultaneously with the rapid heating, SPS can achieve full densification at temperatures several hundred degrees lower than conventional methods.

This lower thermal budget reduces the risk of unwanted phase transformations, decomposition, or thermal stress in the final part.

Final Density: Near-Theoretical Consolidation

The combination of pressure and the unique effects of the pulsed electrical current (which can help clean particle surfaces) allows SPS to consistently produce materials with near-theoretical density.

This means fewer internal voids or pores, leading to superior mechanical, optical, and electrical properties.

Why This Matters: Preserving Material Integrity

The primary advantage of SPS is not just its speed but its ability to consolidate powders while minimizing damage to their delicate microstructures.

Preventing Grain Growth

In conventional sintering, the long exposure to high temperatures causes small grains in the powder to grow larger, a process called coarsening. This destroys the unique properties of nanomaterials.

The short duration of the SPS process is its key strength. It consolidates the powder into a dense solid before the grains have time to grow, preserving nanoscale or nanostructured features in the final material.

Enabling Advanced Materials

By preventing grain growth, SPS is essential for fabricating advanced materials whose properties depend on their fine microstructure.

This includes high-performance thermoelectrics, ultra-hard ceramics, advanced magnets, and novel biomedical implants whose performance is directly tied to maintaining a nanoscale grain structure.

Understanding the Trade-offs

While powerful, SPS is not a universal solution. It has specific limitations that make conventional methods more suitable in certain scenarios.

Sample Geometry and Size

SPS is limited to the simple cylindrical or rectangular shapes of the expensive graphite dies used in the process. Creating complex shapes is difficult and costly. Conventional sintering can handle more complex geometries produced by methods like injection molding.

Material and Throughput

The SPS process is typically batch-based and best suited for high-value materials in research and development or small-scale production. For high-volume, low-cost manufacturing of simple parts, conventional furnace sintering is often more scalable and economical.

Equipment and Operating Costs

SPS systems are significantly more complex and expensive to purchase and maintain than a standard high-temperature furnace and hydraulic press.

Making the Right Choice for Your Goal

Selecting the correct sintering method requires a clear understanding of your material, budget, and final application.

- If your primary focus is researching novel, nanostructured, or temperature-sensitive materials: SPS is the superior choice for its ability to preserve fine microstructures and achieve high density quickly.

- If your primary focus is high-volume production of simple, robust ceramic or metal parts: Conventional sintering often provides a more cost-effective and scalable solution where microstructure control is less critical.

- If your primary focus is rapid material discovery and prototyping: The speed of SPS allows for significantly faster iteration, enabling you to test dozens of compositions in the time it would take to run a single conventional experiment.

Ultimately, your choice depends on whether your goal is to efficiently manufacture a known material or to engineer an entirely new one with precisely controlled properties.

Summary Table:

| Parameter | Conventional Sintering | Spark Plasma Sintering (SPS) |

|---|---|---|

| Heating Method | Slow, external furnace heating | Rapid, internal Joule heating via pulsed DC current |

| Typical Heating Rate | 5–10°C per minute | >300°C per minute |

| Process Duration | Hours to days | 5 to 15 minutes |

| Sintering Temperature | Higher | Lower (by hundreds of degrees) |

| Grain Growth | Significant due to long heat exposure | Minimal, preserves nanostructures |

| Ideal For | High-volume production of simple parts | R&D, nanostructured & temperature-sensitive materials |

Need to preserve nanostructures or accelerate your materials R&D? The rapid, low-temperature consolidation of Spark Plasma Sintering could be the key to your breakthrough. KINTEK specializes in advanced lab equipment, including sintering solutions, to help you achieve superior material properties and faster prototyping.

Contact our experts today to discuss how the right sintering technology can advance your research and development goals.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- What is spark plasma sintering of polymers? Rapidly Create Dense, High-Performance Materials

- What is the difference between spark plasma sintering and flash sintering? A Guide to Advanced Sintering Methods

- What is the plasma sintering method? Unlock Rapid, High-Density Material Fabrication

- What is the process of plasma sintering? Achieve Rapid, High-Performance Material Densification

- What are the applications of spark plasma sintering? Fabricate High-Performance Materials with Precision