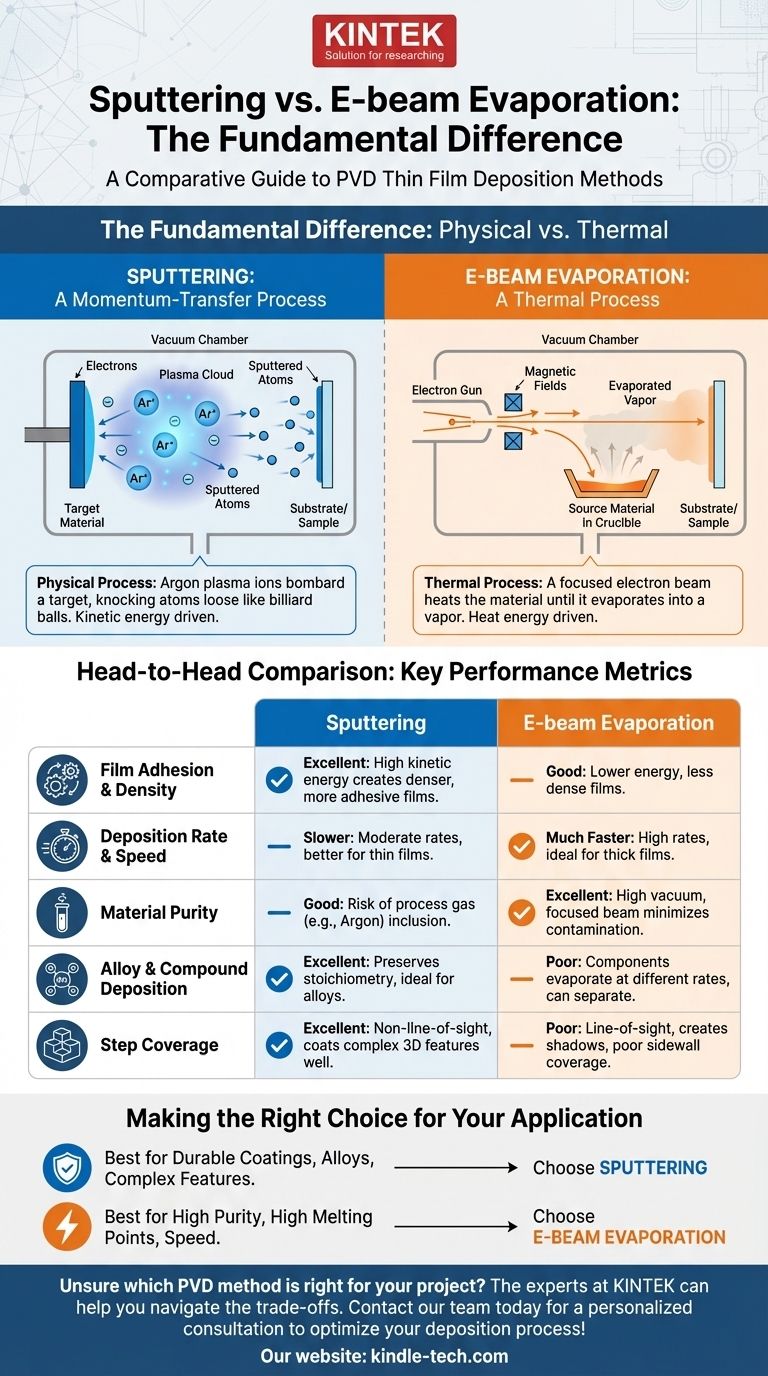

The fundamental difference between sputtering and electron beam (E-beam) evaporation lies in how atoms are removed from the source material. Sputtering is a physical, momentum-transfer process where ions from a plasma bombard a target, knocking atoms loose like billiard balls. In contrast, E-beam evaporation is a thermal process where a focused beam of electrons heats the material until it evaporates into a vapor.

While both are methods for depositing thin films in a vacuum, the choice between them represents a critical engineering trade-off. Sputtering excels at creating dense, adhesive films with excellent uniformity, while E-beam evaporation offers higher purity and much faster deposition rates.

The Physics of Sputtering: A Momentum-Based Approach

Sputtering is a type of Physical Vapor Deposition (PVD) that relies on kinetic energy rather than heat to generate a vapor of atoms for deposition.

The Core Mechanism: The Plasma "Sandblaster"

First, a vacuum chamber is filled with a small amount of an inert gas, typically Argon (Ar). High voltage is applied, which ionizes the gas and creates a plasma—a glowing cloud of positive ions and free electrons.

Ejecting Target Atoms

The source material, known as the target, is given a strong negative electrical bias. This attracts the positive Argon ions from the plasma, causing them to accelerate and collide with the target at high speed.

This bombardment is a purely physical process. The impact of the heavy Argon ions transfers enough momentum to knock out, or "sutter," individual atoms from the target's surface.

Deposition on the Substrate

These sputtered atoms are ejected with significant kinetic energy and travel in various directions. They eventually strike the sample, or substrate, and condense on its surface, slowly building up a thin film one atom at a time.

The Physics of E-beam Evaporation: A Thermal Approach

E-beam evaporation is a thermal PVD method that uses highly focused energy to melt and vaporize the source material.

The Core Mechanism: Focused Electron Heating

In a high-vacuum chamber, a filament emits a stream of electrons. These electrons are accelerated by high voltage and then precisely steered by magnetic fields to form a high-energy electron beam.

Melting and Vaporization

This beam is directed onto the source material, which sits in a water-cooled crucible. The intense, localized energy of the beam rapidly heats the material past its melting point and causes it to evaporate (or sublimate, if it's a material that goes directly from solid to gas).

Line-of-Sight Deposition

The resulting cloud of vapor travels in a straight line—a "line-of-sight" path—from the source to the cooler substrate. Upon contact, the vapor condenses back into a solid, forming the thin film.

Head-to-Head Comparison: Key Performance Metrics

Understanding the differences in their physical mechanisms allows us to compare their performance for specific applications.

Film Adhesion and Density

Sputtered atoms arrive at the substrate with much higher kinetic energy than evaporated atoms. This energy helps them form a denser, more tightly packed film with superior adhesion to the substrate.

Deposition Rate and Speed

E-beam evaporation is generally much faster than sputtering. Because it directly heats the material to high vapor pressures, it can achieve deposition rates that are orders of magnitude higher, making it ideal for creating thick films.

Material Purity

E-beam is typically the purer process. The highly focused beam only heats the source material, and the high vacuum minimizes contamination. Sputtering, by contrast, can lead to the process gas (e.g., Argon) becoming embedded in the growing film, which can be undesirable.

Material Compatibility

Sputtering is highly versatile and is the preferred method for depositing alloys and compounds. Because it ejects atoms physically, it preserves the material's original composition (stoichiometry). E-beam can struggle with alloys, as the component with the lower boiling point may evaporate faster, changing the film's composition. However, E-beam excels at depositing high-melting-point materials like tungsten or tantalum.

Step Coverage

Sputtering provides better step coverage, which is the ability to uniformly coat surfaces with complex 3D features. The sputtered atoms scatter within the chamber, allowing them to coat the sides of features. E-beam's line-of-sight nature creates "shadows" behind tall features, leading to poor sidewall coverage.

Understanding the Trade-offs

Neither method is universally superior; the choice involves balancing competing priorities.

System Complexity and Cost

Simple DC sputtering systems can be relatively inexpensive and easy to maintain. However, more advanced RF or magnetron sputtering systems are significantly more complex. E-beam systems are inherently complex and expensive due to the electron gun, high-voltage power supplies, magnetic steering coils, and the need for a higher vacuum.

Potential for Substrate Damage

Both methods can potentially damage sensitive substrates. The high-energy plasma in a sputtering system can cause surface damage. E-beam systems generate stray electrons and X-rays, which can be highly damaging to sensitive semiconductor devices or certain polymers.

Process Control

Sputtering control is based on gas pressure, power, and target voltage. E-beam control relies on precise management of the electron beam's power and sweep pattern to ensure uniform heating and evaporation.

Making the Right Choice for Your Application

Selecting the correct deposition method requires a clear understanding of your project's primary goal.

- If your primary focus is dense, durable, and highly adhesive films (e.g., optical filters, hard coatings): Sputtering is often the superior choice due to the higher energy of the deposited atoms.

- If your primary focus is high deposition speed and material purity (e.g., depositing thick layers of pure metal): E-beam evaporation is the clear winner.

- If your primary focus is depositing a complex alloy or compound while preserving its composition: Sputtering provides far better stoichiometric control.

- If your primary focus is coating a sensitive electronic device: You must carefully weigh the risk of plasma damage from sputtering against the risk of radiation damage from E-beam evaporation.

Ultimately, the choice hinges on which set of process characteristics best aligns with the required properties of your final film.

Summary Table:

| Feature | Sputtering | E-beam Evaporation |

|---|---|---|

| Primary Mechanism | Momentum transfer (physical) | Thermal evaporation |

| Film Adhesion/Density | Excellent | Good |

| Deposition Rate | Slower | Much Faster |

| Material Purity | Good (risk of gas inclusion) | Excellent |

| Alloy/Compound Deposition | Excellent (preserves stoichiometry) | Poor (can separate) |

| Step Coverage | Excellent (non-line-of-sight) | Poor (line-of-sight) |

| Best For | Durable coatings, complex alloys | High purity, high melting point materials, speed |

Unsure which PVD method is right for your project? The experts at KINTEK can help you navigate the trade-offs between sputtering and E-beam evaporation to achieve the perfect thin film for your application. We specialize in providing lab equipment and consumables to meet your specific research and production needs.

Contact our team today for a personalized consultation and let us help you optimize your deposition process!

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- What is the widely used boat made of in thermal evaporation? Choosing the Right Material for High-Purity Deposition

- What is thermal evaporation used to deposit? A Guide to Metals, Compounds, and Key Applications

- What are the drawbacks of thermal evaporation? Understanding the Limitations for High-Performance Applications

- What is the difference between sputtering and thermal evaporation? Choose the Right PVD Method for Your Thin Film

- What is the meaning of thermal evaporation? A Guide to Simple, Cost-Effective Thin Film Coating